16

WARM AIR FURNACE

THERMOSTAT LOCATION

The thermostat should be located approximately 5 feet above

the floor, on an inside wall where there is good natural air

circulation, and where the thermostat will be exposed to

average room temperatures. Avoid locations where the

thermostat will be exposed to cold drafts, heat from nearby

lamps or appliances, exposure to sunlight, heat from inside

wall stacks, etc.

THERMOSTAT HEAT ANTICIPATOR SETTING:

0.45 AMP (White-Rodgers)

See page 21 for information on connecting optional

accessories such as electronic air cleaners and power

humidifiers.

DANGER

THE FURNACE CABINET MUST HAVE AN UNINTERRUPTED

GROUND.

A GROUND WIRE IS PROVIDED IN THE ELECTRICAL

JUNCTION BOX.

DO NOT USE GAS PIPING AS A GROUND.

FAILING TO GROUND THE FURNACE PROPERLY CAN

RESULT IN ELECTRIC SHOCK RESULTING IN PERSONAL

INJURY OR DEATH.

WARNING

THIS FURNACE IS EQUIPPED WITH A BLOWER DOOR

SAFETY SWITCH. DO NOT DISABLE THIS SWITCH. FAILURE

TO FOLLOW THIS WARNING CAN RESULT IN ELECTRICAL

SHOCK, PERSONAL INJURY, OR LOSS OF LIFE.

In the United States, all electrical work must be in accordance

with the latest edition of the National Electrical Code, ANSI /

NFPA 70, in Canada, all electrical work must be in accordance

with the latest edition of CSA-C22.1, Canadian Electrical Code

Part 1, and any applicable local code.

Although a suitably located circuit breaker may serve as a

service switch, a separate service switch is recommended.

A separate in service switch is necessary if the circuit breaker

is in a location where accessing it would require getting close

to the furnace, or if the furnace is located between the main

electrical panel and the entry to the furnace room. The

furnace switch (service switch) should be clearly labeled and

installed in a location where it is not likely to be mistaken as

being a light switch or similar control.

FURNACE CONNECTION

120V: The furnace is shipped fully wired except for the

connections to the house wiring. The furnace power

connections are made in a junction box inside the blower

compartment. The junction box is factory installed on the left

hand side however, it may be moved to the right hand side.

The junction box contains a BLACK wire to be connected with

L1 (hot), a WHITE wire to be connected with L2, the Neutral,

and a GREEN wire to be connected to the ground.

Use good quality wire nuts; e.g. Marrette® connectors, Ideal®

wire nuts, etc.

IMPORTANT: USE COPPER CONDUCTORS ONLY

If the junction box must be moved to the right hand side:

1. Unfasten the junction box from the left hand side.

2. Remove the right side panel knockout.

3. Remove the junction box cover hook screw and reinstall it

on the opposite side of the box.

4. Fasten the junction box to the right hand panel.

NOTE: L1 (hot) and L2 (Neutral) polarity must be observed

when making field connections to the furnace. The ignition

control may not sense flame if L1 and L2 are reversed. The

ground is also essential.

NOTE: The furnace shall be installed so the electrical

components are protected from water.

LOW VOLTAGE WIRING

The low voltage terminals are located on the control board

mounted to the blower assembly; see Figure 11 on page 19.

The furnace is prewired for air conditioning. Insert the

thermostat and air conditioner contactor low voltage wiring

through the bushing provided in the side panel. Route the

control wiring through the blower compartment to the

24 volt terminal screws.

THERMOSTAT

The room thermostat must be compatible with the integrated

control in the furnace. Electromechanical thermostats should

be rated 30 V / 1.5 amps.

Most electronic or microprocessor based thermostats except

those with "current robbing" circuits should work

satisfactorily. Consult the instructions of the thermostat

manufacturer for technical and installation details.

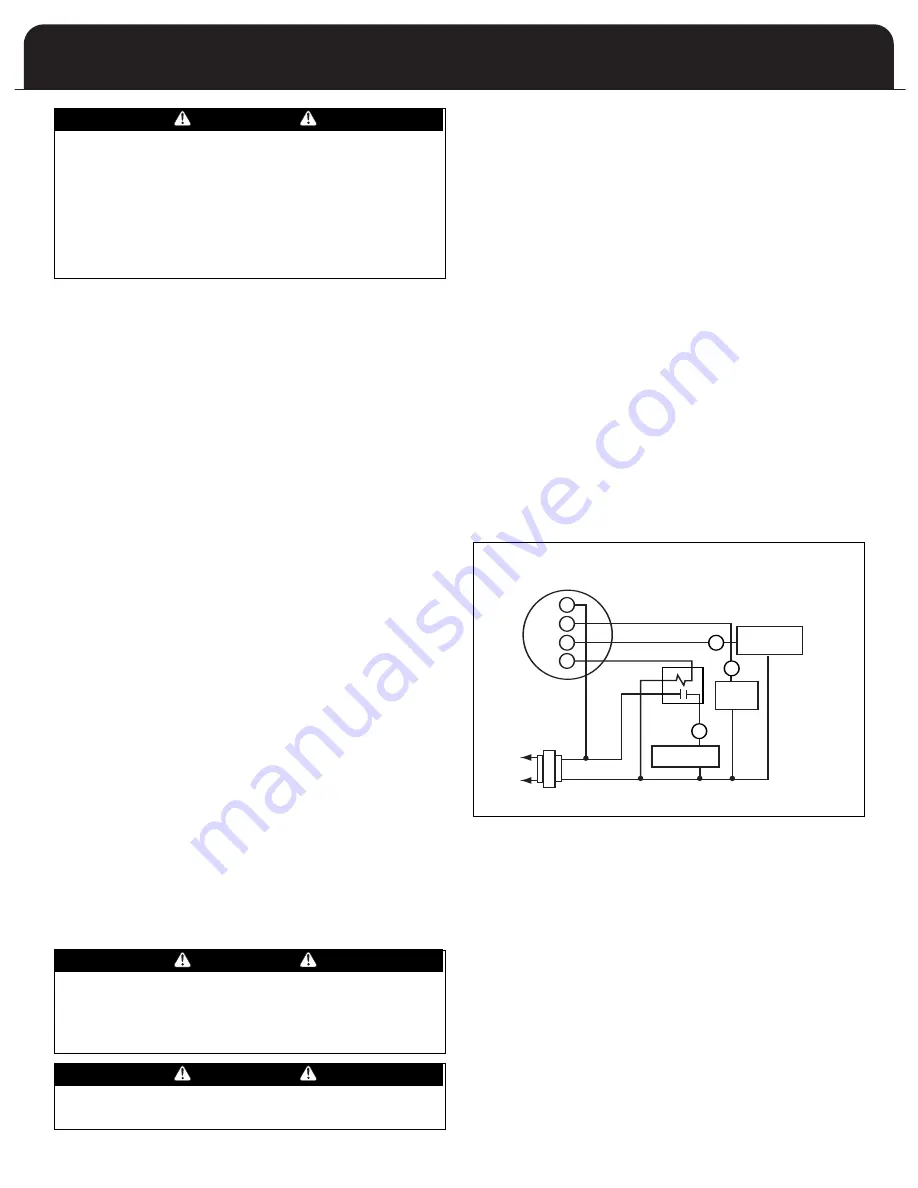

Most compatibility problems can be overcome by the use of

an isolation relay. The isolation relay should be SPST with a 24-

volt coil. The switch ratings should be a minimum of 0.5 amps;

see figure 9 below.

The thermostat and control wiring should be a minimum of 18

AWG copper. Excessive lengths of wire may result in enough

voltage drop to impair the proper functioning of the furnace.

For thermostat wires in excess of 25 feet, use 16 AWG; 50 feet,

use 14 AWG.

Figure 13: Isolation Relay

THERMOSTAT

COOLING

CONTACTOR

FAN

RELAY

HEATING RELAY

24V

115V

R

G

Y

W

Y

G

W

Figure 9: Isolation relay

CAUTION

ELECTRICAL WIRING AND COMPONENTS MUST BE PROTECTED

FROM MOISTURE, INCLUDING WATER AND CONDENSATE.

Summary of Contents for F80A

Page 24: ...23 MODEL F80A 50V51 250...