24

WARM AIR FURNACE

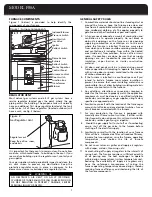

TABLE 11: GENERAL TROUBLESHOOTING WHITE-RODGERS INTEGRATED FAN CONTROL

IF

AND

CHECK or REPAIR

Induced blower does

not energize

2 Flash code does not come o n

1.

Induced blower wiring.

2.

Induced blower.

Induced blower does

not energize

2 Flash code does come on

1.

Pressure switch stuck closed.

2.

Pressure switch is mis-wired or jumpered.

Induced blower is

energized

3 Flash code does not come o

n

Wait for the pre-purge to expire.

3 Flash code

comes on

Induced blower turns off

1.

Pressure switch stuck in the open position.

2.

Pressure switch, tubing and wiring.

3.

Obstruction in furnace venting that is preventing proper combustion airflow.

Pre-purge time h as

expired

HSI element does not glow r

ed

within 10 seconds.

1.

Broken or damaged HSI element.

2.

Broken or damaged HSI element leadwires.

HSI element i s glow-

ing red.

No other visible control system

action

Wait for HSI element warm up time to expire.

HSI element warm u p

time has expired a nd

main valve has been

energized.

Main valve does not light within

trial for ignition period

1.

Induced blower moving main burner gas away from the HSI element.

2.

Inlet gas pressure too low for main burner ignition.

3.

Input line voltage too low to heat HSI element.

4.

HSI element incorrectly positioned.

5.

Clogged or incorrect main burner orifice.

Main burner lights

within trial for ignition

period.

Main valve i s de-energized a

t the

end of the trial for ignition period.

If main flame i s not sensed during

trial for ignition, system will shut o ff

HSI element and main gas flow,

then g o through another purge

period and initiate another ignition

trial. A total o f 4 ignition trials will

be attempted before the system

goes into lockout.

1.

Line voltage to L 1 terminal of

must be 120 volts with reference to furnace

chassis.

2.

Furnace must be reliably connected to earth ground.

3.

Induced blower moving main burner flame away from the flame sensor rod.

4.

Inlet gas pressure too low for proper flame sensing.

5.

Flame sensor rod contaminated or in incorrect position.

Main burner stays o n

after the end of t

he

trial

for ignition p

e-

riod.

Circulating fan is not turned on after

30-second time delay.

1.

Wiring between system control and IFC. Proper operation of 50V51-250 IFC.

Main burner goes o ut

before thermostat call

for heat ends.

4 Flash code comes on

1.

2.

Open high limit switch.

High limit wiring in good condition and securely connected.

Main burner goes o ut

before thermostat call

for heat ends.

4 Flash code does not come on

1.

2.

Induced blower moving main burner flame away from flame sensor rod.

3.

Pressure switch has opened.

1.

2.

Open flame rollout switch

Rollout switch wiring in good condition

4.

Flame sensor rod ceramic or leadwire overheated.

Gas supply / flow reduced or interrupted.

5 Flash code comes

on.

1 Flash code comes

on.

After 1-hour

lockout

reset delay, control

will reset and initiate

a new ignition s e-

quence i f the call f or

heat is still present.

1.

Gas supply off or at too low a pressure to operate furnace.

2.

Damaged or broken HSI element.

3.

Line voltage to L1 terminal of 50V51-250 IFC must be 120 volts with reference t o the

furnace chassis.

4.

Furnace is not properly connected to earth ground.

5.

Flame rod contaminated or in incorrect location.

6.

Hot surface element located in incorrect position.

7.

Hot surface element or flame sensing rod wiring i n good condition and properly con-

nected.

8.

5 flame failures caused by opening limit switch o r flame rollout switch, within t

he

thermostat call for heat. Turn thermostat down below room temperature t o reset

control. Check for blocked air filter, closed ducts, etc.

50V51-250

Summary of Contents for F80A

Page 24: ...23 MODEL F80A 50V51 250...