9

Physical installation

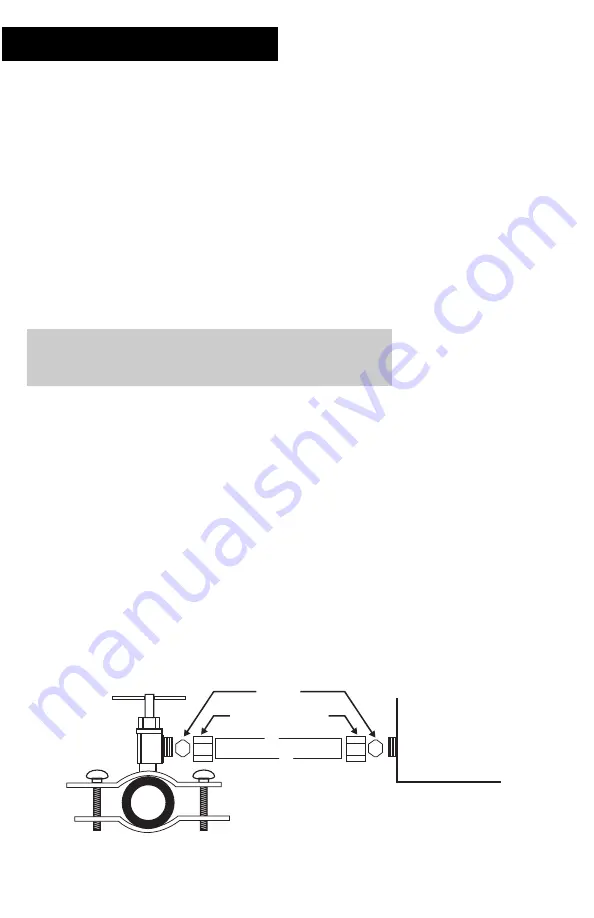

Final installation steps for all mounting locations

•

Install the saddle valve on the nearest cold water supply

pipe (see the instructions on the package). If applicable,

connect the saddle valve upstream of any type of water

softener.

•

After the saddle valve has been installed and 1/4” copper

tubing fitted to the valve, but before attaching the copper

tubing to the float and valve assembly, turn the saddle valve

to the open position and discharge the water into a bucket

or pan. This will allow the water to void the line of any

debris that may have accumulated during the installation

process.

•

Attach the 1/4” copper tubing to the float and valve

assembly with the ferrule and compression nut (provided).

Caution: The float and valve assembly must not turn when

tightening the copper tubing compression fittings to the

humidifier water reservoir pan fitting.

•

Turn the water supply on at the saddle valve.

•

Check the water level in the water reservoir pan to ensure

it is 1-1 1/2” deep.

IMPORTANT:

In installations where accidental overflow could cause water

damage, connect a drain hose from the humidifier water

reservoir pan overflow tube to a drain. Do NOT use a soldered

joint because the overflow tube will become heated and warp

the water reservoir pan.

1/4" Copper Tubing

Compression Nut

Ferrule

Saddle Valve

Humidifier Water

Resivoir Pan

NOTE:

The following items are

located in the bag

identified:

“707 SM/STD Hardware Kit”:

•

Saddle valve assembly