1. If the furnace and air conditioner are on separate

thermostats, turn the furnace thermostat off during the

cooling season to prevent simultaneous operation of the

heating and cooling systems. Reverse the procedure during

the heating season.

Adjust thermostat temperature and fan settings according

to the thermostat manufacturer’s recommendations. It is not

recommended to vary the temperature settings more than 5

degrees. Varying the temperature more than 5 degrees or

turning the thermostat off for periods less than 12 hours can

actually cost you more in energy consumption than keeping

the temperature constant. Consider indoor plants and pets

when varying the temperature from the normal comfort

level.

2. IMPORTANT: Wait at least 3 minutes after turning the air

conditioner off before trying to restart. If an attempt is

made to start the compressor before the refrigerant

pressures are equalized, the compressor motor may trip on

its overload. An additional waiting period will be required

before restarting.

OPERATION INSTRUCTIONS

1. Keep the condenser (outdoor coil) clean. Wash it down with

a garden hose if necessary.

For continuing high performance and to minimize possible

equipment failure, periodic maintenance must be performed on

this equipment. Frequency of maintenance may vary depending

upon geographic areas, such as costal applications.

MAINTENANCE INSTRUCTIONS

WARNING

BE SURE THE UNIT DISCONNECT IS IN THE “OFF”

POSITION AND THAT ALL ELECTRICAL POWER TO THE

UNIT IS TURNED “OFF” BEFORE CLEANING THE SYSTEM.

2. Remove any loose grass, leaves, papers, etc., from the area

around the condenser coil. These could reduce the air supply

through the coil and reduce the amount of cooling.

3. Always install and keep system filters clean. Consult your

licensed Contractor for filter replacement schedules and

instructions.

WARNING

SERIOUS PERSONAL INJURY OR DEATH MAY RESULT IF

WATER SPRAY IS DIRECTED TOWARD LIVE ELECTRICAL

CONNECTIONS OR POWER SOURCES.

Model

5

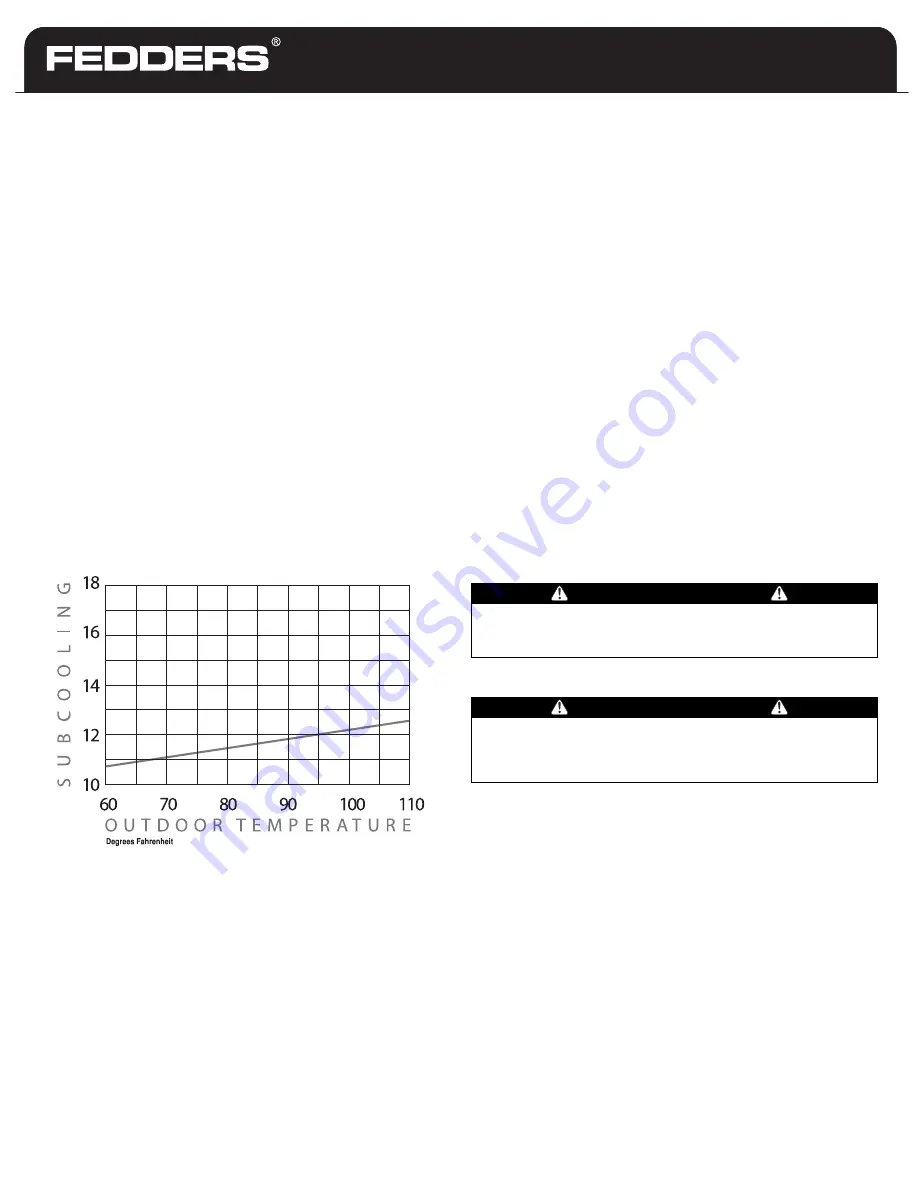

SUB-COOLING CHARGING

Coils with TXVs should be charged 10-12 degrees (+ or – one

degree) of sub-cooling. For proper sub-cooling readings, a

standard high side gauge is required for pressure readings.

Use the chart below to determine the required sub-cooling value.

INSTRUCTIONS

1. Measure the outdoor air temperature. (T1)

2. Measure the liquid line pressure at the outdoor unit and

determine condenser refrigerant temperature by the scale on

the high side pressure gauge. (T2)

3. Measure the liquid line temperature on the liquid line at the

outdoor unit. (T3)

4. Subtract T3 from T2. (T2 – T3) This is the subcooling value.

Compare this value and the outdoor temperature (T1), to the

charts below. If the value is below the line, add refrigerant. If

the value is above the line, remove refrigerant charge.

NOTE: For the majority of installations no adjustment to the

TXV setting is required. However, if the measured superheat

at the evaporator is less than 4° or greater than 8° an

adjustment is required. The adjustment stem is at the base of

the valve under the flare nut. To increase superheat tighten

the stem clockwise and to decrease superheat back-out the

stem counter-clockwise. Use a 1/4” refrigeration service

wrench for this function.

NOTE: When removing refrigerant, always use standard reclaim

procedures.

FINAL CHECKS FOR INSTALLER

1. Ensure that all wiring is routed away from tubing and sheet

metal edges to prevent rub-through or wire pinching.

2. Ensure that all wiring and tubing is secure in unit before

adding panels and covers.

3. Tighten service valve stem caps to 1/12 turn past finger tight.

4. Leave Owner’s Manual with owner. Explain system operation

and periodic maintenance requirements outlined in manual.

°F

°F

°F

°F

°F

°F

SUB-COOLING CHART FOR UNITS WITH TXV