- 25 -

MAINTENANCE

LED Light Replacement

1.1

LIGHT REPLACEMENT

1.

Remove both rear doors as described in the “Door Removal” section of this manual.

2.

Remove shelving from unit through rear door opening as described in the “Shelving Installation and

Removal” section of this manual.

3.

Unplug appropriate light cord from socket and remove shelf from unit through rear door opening.

All lights are LED Bar type. If replacement should become necessary, follow the directions below to

replace LED lights.

TOP LIGHT

5.

Unplug cord from light

6.

Carefully pry plastic clip tab away from lip on LED light body, with a slight

rotational motion, disengage the clip locking tab on each of the plastic clips.

Install replacement LED by inserting lip on replacement LED body under the

locking tab on plastic clip and snap into place

Re-install cord plug.

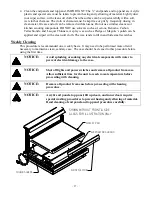

SHELF LIGHTS

7.

Unplug cord from light

8.

Use putty knife to pry LED light body from Shelf and or Top Light Liner. It may be

useful to slide the putty knife along the length of light once putty knife is between

LED light body and component surface. (it is recommended to remove shelves

from case when replacing LED lights)

9.

Remove residual adhesive tape from shelf / top light liner and clean surface with

alcohol

10.

Remove liner from Double Sided Tape on replacement Light

11.

Use small holes in Top Light Liner & Shelves as a locational guide for LED

placement

12.

Mount light and apply pressure along the length of LED body to ensure good

adhesion

Re-install shelf and cord plug.

![FRIGOGLASS Retro [R290] LC User Manual preview](http://thumbs.mh-extra.com/thumbs/frigoglass/retro-r290-lc/retro-r290-lc_user-manual_2338098-001.webp)