15. To put circuit breaker into service push

interlock to left, insert

lever in

bottom

3. Make sure all retaining rings are in place.

bole of the

mechanism (Figure 8) and

4. Surfaces marked “F” should be lubricated by thin

upward stroke rack breaker into operating position.

of “Conducto-Lube

before assembly.

Remove

lever. interlock

should

in

Contacts must be inspected after every known short circuit

and should also he

at regular in-

spect& periods. If contacts are found to be worn or

cessively pitted they should be dressed or replaced.

When

reinstalling the arc chutes, adjust the

retaining screws on the arc chute retaining bar so that

the contact insulating block clears the arc chute base when

the breaker is closed.

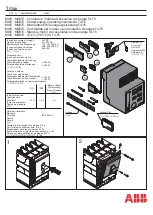

CONTACT ASSEMBLY

repair or replace

arcing contacts,

follows (Figure 11)

1.

stored energy

2. Remove arc chutes and

barrier.

3. Remove insulating block and

fork assembly.

4. Tighten

arcing

adjusting screw

Figure 9 Figure

PART 4

MAINTENANCE

The breakers with all component

have been

tested for performance as per

Standards SG

3 and ANSI

and proved to be satisfactory

wide margin of safety.

solid and

retaining pins.

6. Remove arcing

contact pivot pin and replace

arcing contacts.

contacts should be replaced at

one time.

6. Make

nylon bushings on arcing

pivot pin

are in place and in good condition, when replacing

arcing contact.

A periodic maintenance

should be established. An

annual inspection should

made for clean,

applications. More frequent inspections should be made

for dirty, corrosive or high-use applications.

Reassemble following the reverse

of operations

and adjust per Figs. 10 and 11. In most

it is not

to replace contacts, but occasional

and readjustments are

recommended.

The following instructions and

should be fol-

lowed carefully:

CONTACT ADJUSTMENT

Figure 10 and 11

MAIN AND ARCING CONTACTS ADJUSTMENT

FOR

AND

BREAKERS

To replace stationary arcing contacts (Figure

remove

unit pole assembly, replace main stud and arcing contact

assembly, part 1151-9939, for 600A breaker and

9937 for

breaker.

Adjust

as per

10, 11 12.

“A” Main Contact Pressure

Over Travel Mains

Arcing Contact Press

Gap (distance) between

mains when arcing

contacts touch

42-50 lbs., measured at

point of contact

lbs., measured at

of contact

&

(Fig. 10)

CHECK POINTS

-Figure

11 and 12

1. Stationary arcing contacts

make sure that retaining

screws and contacts are tight.

2. Main contacts should be clean and free