29

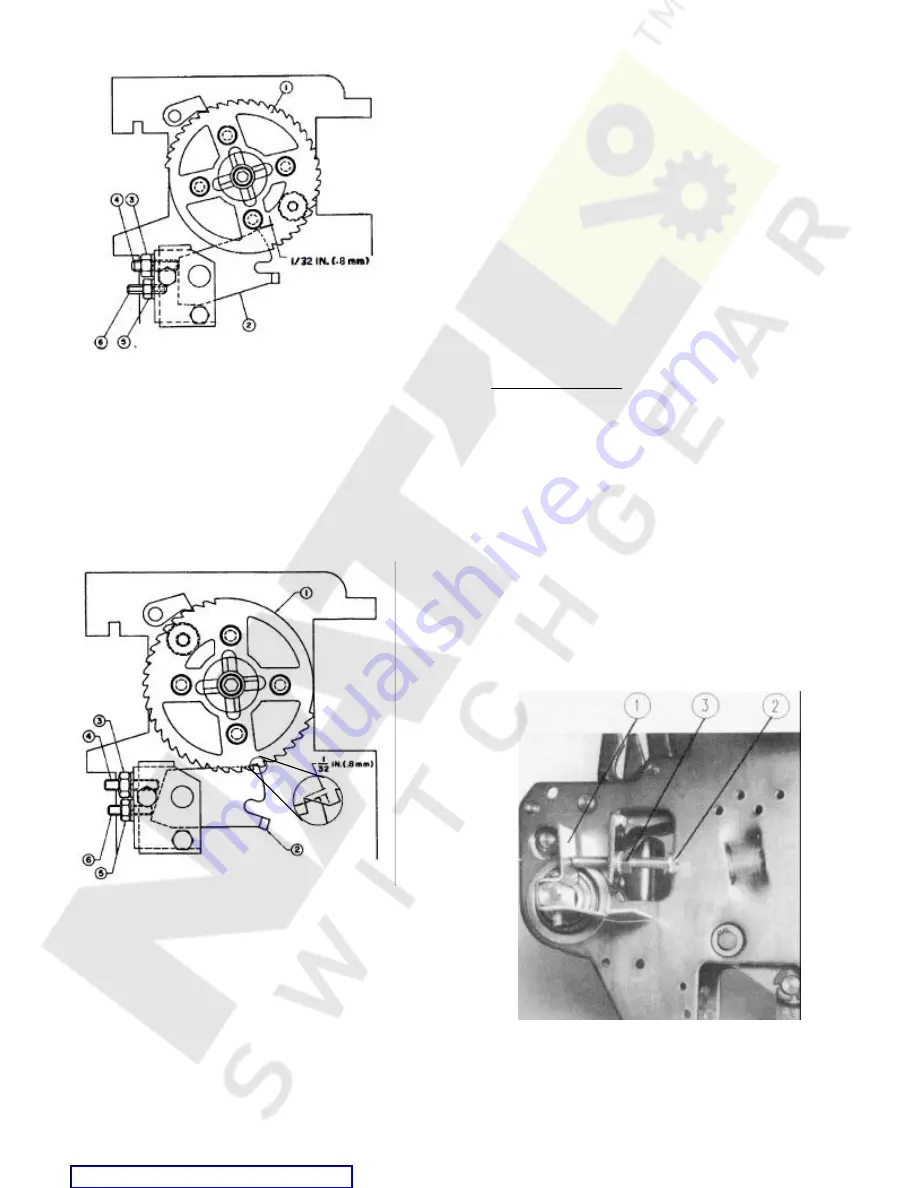

FIG. 8.3.1 TRIP LATCH ADJUSTMENT

1.

TRIP SHAFT LEVER

2.

ADJUSTMENT SCREW

3.

LOCKNUT

TURNING THE STOPSCREW (ITEM 4) ADJUST THE CLOSE LATCH

HEIGHT UNTIL THERE IS APPROXIMATELY 1/32 INCH (0.8 MM)

CLEARANCE BETWEEN THE SPACER AND THE NOSE OF THE CLOSE

LATCH. HOLD THE STOPSCREW SECURELY WITH THE ALLEN WRENCH

WHILE TIGHTENING THE LOCKNUT.

REFERRING TO FIGURE 8.2.2, THE ADJUSTMENT PROCEDURE FOR

THE LOWER STOP SCREW IS AS FOLLOWS. BE SURE THAT THE CLOSING

SPRING IS DISCHARGED AND THAT THE MAIN CONTACTS ARE OPEN.

LOOSEN LOCKNUT (ITEM 5). MANUALLY DEPRESS THE CLOSE LATCH

(ITEM 2) UNTIL IT STOPS ON THE LOWER STOPSCREW (ITEM 6).

TURNING THE STOPSCREW, ADJUST THE CLOSE LATCH HEIGHT UNTIL

THERE IS APPROXIMATELY 1/32 INCH (0.8 MM) CLEARANCE BETWEEN

THE RATCHET WHEEL TOOTH VALLEY AND THE NOSE OF THE CLOSE

LATCH. HOLD THE STOPSCREW SECURELY WITH THE ALLEN WRENCH

WHILE TIGHTENING THE LOCKNUT.

8.3 TRIP LATCH ADJUSTMENT

THIS ADJUSTMENT, LOCATED ON THE OUTSIDE OF THE LEFT

HAND SIDE MECHANISM SIDE PLATE, CONTROLS THE ENGAGEMENT OF

THE TRIP LATCH ROLLER. IF THIS ENGAGEMENT IS INSUFFICIENT, THE

ROLLER MAY RELEASE DURING THE CLOSING STROKE, RESULTING IN

FAILURE TO CLOSE. THE MAIN CONTACTS MAY MOVE BUT NOT

COMPLETE THE TRAVEL.

TO ADJUST, THE FOLLOWING PROCEDURE SHOULD BE USED:

WITH TRIP SHAFT LEVER (ITEM 1 ) RESTING AGAINST ADJUSTING

SCREW (ITEM 2), LOOSEN LOCKNUT (ITEM 3) AND TURN ADJUSTING

SCREW COUNTER-CLOCKWISE TWO TURNS. CLOSE THE BREAKER

AND SLOWLY TURN THE SCREW CLOCKWISE UNTIL THE UNIT TRIPS.

NOW TURN THE SCREW COUNTER- CLOSKWISE ONE AND ONE

QUARTER TURNS AND TIGHTEN THE LOCKNUT.

FIG. 8.2.2 CLOSE LATCH ADJUSTMENT

REFERRING TO FIG. 8.2.1 THE ADJUSTMENT PROCEDURE FOR THE

UPPER STOPSCREW IS AS FOLLOWS:

THE RATCHET WHEEL ASSEMBLY IS MADE UP OF TWO PLATES

RIVETED TOGETHER. THE TWO PLATES ARE HELD APART BY

SPACERS LOCATED BETWEEN THE PLATES ON THE FOUR RIVETS.

ROTATE THE RATCHET WHEEL UNTIL ONE OF THE SPACERS IS

DIRECTLY ABOVE THE NOSE OF THE CLOSE LATCH (ITEM 2). LOOSEN

LOCKNUT (ITEM 3).

FIG. 8.2.1 CLOSE LATCH ADJUSTMENT

1.

RATCHET WHEEL

2.

CLOSE LATCH

3.

UPPER LOCKNUT

4.

UPPER STOPSCREW

5.

LOWER LOCKNUT

6.

LOWER STOPSCREW