Chapter 4: Wiring the INTEGRITY Lightbar in the Vehicle

24

Integrity Lightbar

5.

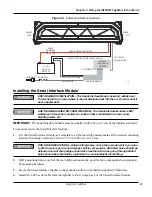

Install the three-foot-long, 24-conductor cable from the lightbar to the J1 input connector of the Serial

Interface Module.

NOTE:

Powering multiple devices with a common control wire may cause one or more devices to briefly

remain functional after signal power is removed. For example, due to the high input filter capacitance, a

strobe supply can briefly supply the current required to signal a lightbar function to remain on. If necessary,

use a relay to isolate devices with large filter capacitors (Figure 4.2). All components/wires are user-supplied.

SHOCK HAZARD—Strobe and HID light systems generate high voltages. Disconnect

power from the system and wait at least 5 minutes before opening the unit. Do not

apply power to the unit while the unit is open. Failure to follow this warning could

result in serious injury or death.

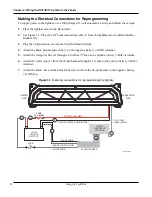

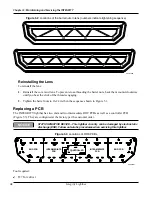

Figure 4.2 Relay for isolating devices with large filter capacitors

290A7446

+12 Vdc

CONTROL LEAD

(12 Vdc SIGNAL ACTIVATED)

RELAY

FUSE*

STROBE SUPPLY

*FUSE AMPERAGE DEPENDS ON AMPERAGE OF DEVICES

Wiring the Serial Interface Module

FUSE ELECTRICAL SOURCES—Always fuse current/voltage sources with a fuse

connected near the power source. Be sure that the fuse is properly rated to protect

the electrical load, the wiring and the connectors used in the circuit. Failure to

follow this notice could result in vehicle or equipment damage.

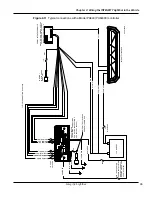

This section is an overview of default settings that are activated when connecting LED and Mode control

wires to 12 Vdc (+BAT). The basic light functions of the lightbar must be controlled by an installer-supplied

control head. All programming and changes to default settings should be done after quick testing the lightbar

and before installation. Programming is covered in “Programming Priority Modes 1, 2, 3, and Intersection”

on page 17.

For a description of the control wires from the Serial Interface Module, see Table 3.3 on page 19. For typical

installations with common controllers and switch boxes, see the wiring schematics starting on page 21 in

Chapter 4.

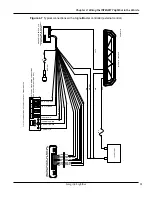

For wiring the controller functions to the 24-pin cable harness of the Serial Interface Module, see Table 3.2

on page 16 and the figures on pages 29 and 30. If additional wire is necessary for the harness (except

ground), 22 AWG wire is adequate. The ground wires must be extended with 16 AWG or thicker wire.

Priority Modes 1, 2, and 3

To activate a priority mode, apply 12 Vdc (+BAT) to a mode control wire. Mode 3 (black/red) overrides

Mode 2 (blue/white), and Mode 2 overrides Mode 1 (blue). You can program one of the flash patterns in

the lightbar to each Mode input.

Summary of Contents for Integrity44

Page 2: ...blank page ...