27

Installation, Maintenance, and Service Manual

Federal Signal

www.fedsig.com

Wiring the Valor in the Vehicle

independent ground signal to turn on each head (Figure 7).

For the switch setting in the Serial Interface Module, see “Selecting External

SignalMaster Control” on page 14. To activate the light bar’s internal SignalMaster

controller, apply 12 Vdc (+BAT) to the SignalMaster control wires (Table 7 and

Figure 5).

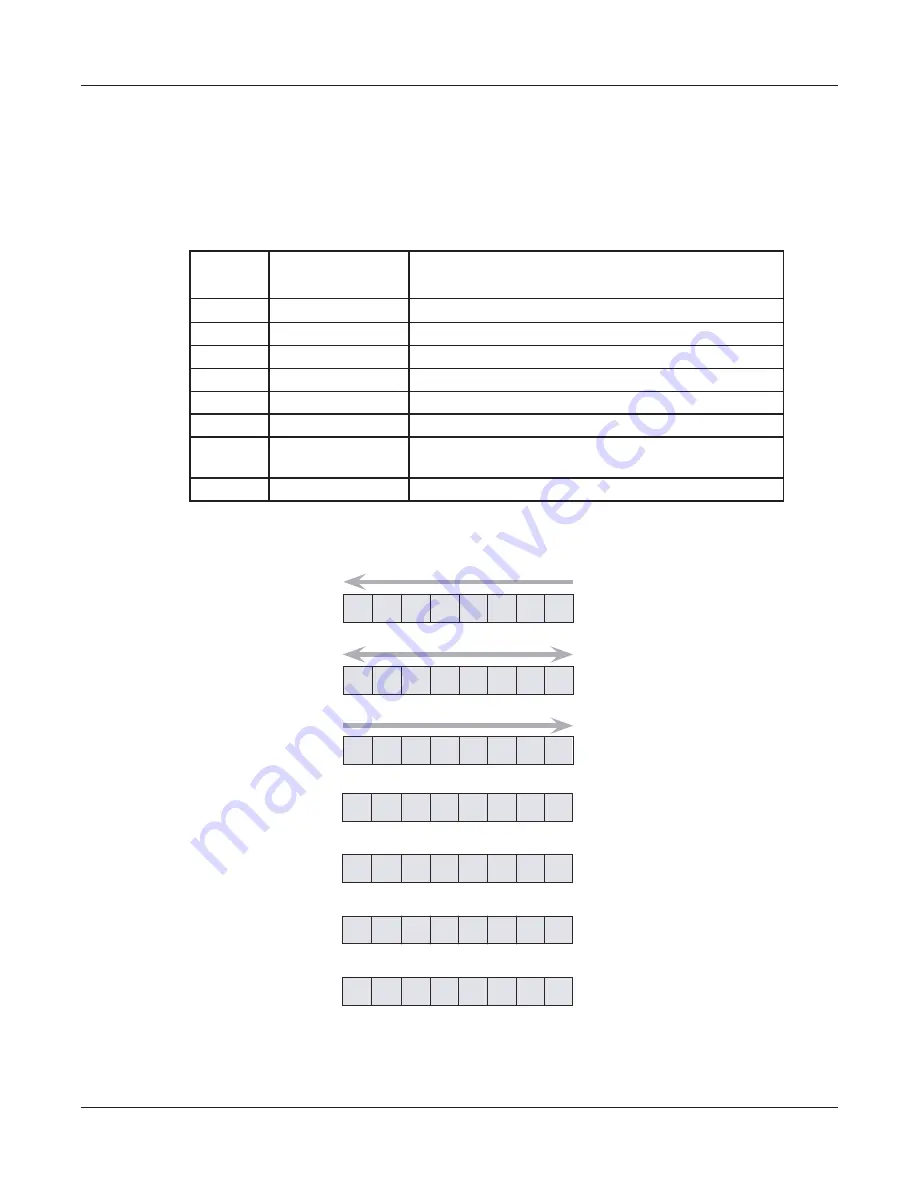

Table 7 SignalMaster control wires and warning patterns

Warning

Pattern

Control Wires

Description

LEFT

Red

Rear LEDs flash from right to left

CENTER Green

Rear LEDs flash from center out to both sides

RIGHT

Green/Black/White

Rear LEDs flash from left to right

WARN 1

Orange/Green

Outer LEDs alternate

WARN 2

Orange

Two outer LEDs alternate

WARN 3

Blue/Red

Outer LEDs and two inner LEDs alternate

WARN 4

Red/Green

Outer LEDs and two inner LEDs flash, then the LEDs

between the inner and outer LEDs

FAST

White/Red

Operates the selected pattern 50 percent faster

Figure 5

SignalMaster flash sequences

290A6578D

LEFT

CENTER

RIGHT

WARN 1

WARN 2

WARN 3

WARN 4

2

1

1

2

3 4

3

4

3

4

5

6

7 8

2

1

2

2

1

1

1

1

1

1

2 2

2 2

2

2

2

1

6

5

4

3

2 1

7

8

1

1

2 2

1

1