- 8 -

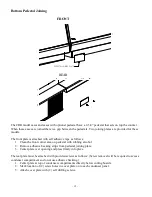

CORD OPTIONS

CORD OPTION 1: The electrical cord is shipped from the factory protruding from the A 2-3/4” hole

located in the bottom rear corner of the condensing compartment and does not require a hole to be drilled

into the cabinet. (You may need to reach up into 2-3/4” hole to retrieve cord.)

CORD OPTION 2: The power cord can also be allowed to drop into counter interior space. This option

does not require any rewiring of the case, but does require a hole to be drilled into the back of cabinet.

1. Before placing the case onto the counter remove the (6) screws holding the condenser cover and remove

the condenser cover.

2. There is a 2-3/4” hole in the lower corner of the compartment and a 2-3/4”hole plug in the compartment

back. Remove the 2-3/4” plug from the back hole and place it into the bottom hole.

3. Install and fasten the case onto the counter.

4. Drill a 1-1/2” hole through the counter back in the location of the 2-3/4” hole for power cord to be

dropped into cabinet compartment.

5. Reinstall the condenser cover and the (6) screws.

OPTION 3: An electrical cord connection hole is provided in the rear control panel next to the controls. A

1-1/2”dia hole through the counter is not required for this option. NOTE: Only a licensed electrician must

perform the electrical work required to move the cord to this optional position.

DANGER:

Electric shock hazard. Do not operate unit with panels removed.

1. Before or after the case has been installed onto the counter remove the (6) screws holding the condenser

cover and remove the condenser cover.

2. Remove the (4) screws holding the rear frame panel located under the door track. Loosen the (4) screws

holding the cutting board under each end of the cutting board. Tilt and lift the rear panel out from behind

the cutting board.

3. Remove the 7/8” hole plug located next to the controls in the control panel. Disconnect power cord

connections and move cord and cord strain relief from bottom hole in frame channel to the 7/8” hole in

the control panel. Reconnect power cord and plug bottom in frame channel with the 7/8” hole plug

removed from the control panel.

4. Reinstall the condenser cover and the rear frame panel and retighten the cutting board mounting screws.

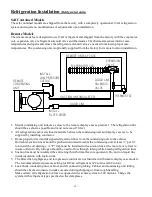

Refrigerated CRB Self Contained Models

Cabinet Preparation

The CRB Self Contained models have a large condenser compartment hanging from the bottom of case that

contains the condenser/condensate evaporator unit. This compartment hangs inside the cabinet

compartment. The interior of the cabinet must be open to allow space for this compartment and air

movement. The countertop must be cut to allow the case’s base and condenser compartment to drop into

the cabinet interior. Use the diagram below for cutout dimensions.

The condenser air inlet and discharge louvers are located on each side of the case condenser compartment.

The cabinet interior must have a divider that isolates intake and the exhaust sides of the condenser air. The

provided gasket must be attached to case in divider location to insure a seal between the air intake and air

discharge sides of condenser compartment. The Louvers provided must also be installed on each side of

these compartments for required condenser outside cabinet air exchange. The louvers can be installed in

either the front or the rear of the cabinet, as long there is a min. of 8”air space (drawing shows louvers in

rear for reference only). The cabinet compartment must not be used for storage or air restriction may occur.

(2) ½” dia. case fastening holes will need to be drilled through the counter top surface to attach case to

counter with ¼” X 2” screws provided. Use the diagram below for hole placement location.

IMPORTANT: Federal Industries reserves the right to deny warranty if the cabinet is not divided

internally and the cabinet louvers not installed properly, blocked or located near a source of heat.