2

Welcome among the customers of our products!

We hope that our new type, economic, reliable water heater, which requires little room will satisfy

you in all respects. To have an undisturbed operation, long durability and economical running please

study the Instructions for Use thoroughly.

The heating appliances are adjusted to the desired type of gas. The devices equipped with a

room thermostat or with another switching type controller (e. g.: with a timer) work fully automatically.

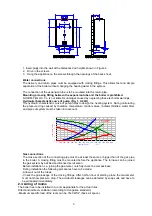

The appliances can be used either for opened or closed loop heating systems. For a closed loop

heating system the suitable fittings- a closed expansion tank, a safety valve, a pressure gauge are

needed. Although the appliance is not suitable for direct connection to floor heating systems,

appropriate auxiliary fittings allow this application.

The boilers can be deployed altogether with a water heater. If the regulations for the chimney

or for the air space make it required, a blocking system must be used.

Major particulars for the sake of your safety and peace

Boilers can only be operated by a person who has learnt their operation, knows the fire safety

regulations and is not disabled.

If the regulations laid down in the Instructions for Use are not met, the operator of the appliances is

liable for all the ensuing consequences. It is PROHIBITED to take hot water directly out of the boiler or

out of the heating system!

If the operator notices that the pilot extinguishes on its own (e.g. as a result of gas cut-off),

switch it on after about a minute, if it extinguishes again or you notice any kind of disorder (e.g. gas

leakage, excessive smoke, unpleasant smell, etc.) put the appliance out of action. Turn off the gas tap

under the appliance and cut off the current.

In case of a gas leakage turn off the gas valve under the appliance, air the room (meanwhile

do not switch on any electric appliance, do not move any electric wall plug, do not employ an open

fire). In case of further gas leakage turn off the main gas valve under the gas meter. The gas leakage

must be reported to the local gas company.

Disorders can only be fixed by a skilled serviceman. The appliance MUST NOT be used until

the disorder is fixed!

In case of failure of the appliance, skilled repairmen of gas appliance services must be

contacted (addresses of service networks is enclosed). For housekeeping purposes in the room where

the boiler is mounted, only one - in a flat maximum two-either 11,5 kg or 23 kg loading weight gas

cylinders can be stored with a total loading weight not more than 35 kg.

Flammable materials cannot be kept under and nearer than 60cm beside the appliance. The

instructions for use must be preserved and kept in a place where it is available for the operator. If it

gets lost it must be substituted.

1.Technical parameters and dimensions

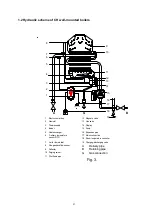

The C24H boilers are equipped with an atmospheric injector burner, a water circulating pump, a

thermoelectric flame safety device, a manually ignited pilot burner and a flue-gas connection to be

joined to a chimney having natural air flow. The appliances can be used for opened and closed loop

heating systems as well.

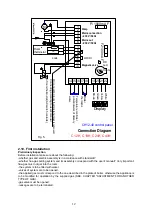

Control unit: ELEKTRONIKA MECHANIKA CH-12-40

Water temperature control: T7335 HONEYWELL NTC thermistor

Safety water temperature limiter, flue-gas backflow sensor: 2pcs. of EMERSON 36TXE-12732

Accelerating pump: WILO EARS 20/70

Combined gas valve: HONEYWELL V4600 1367-230V-50Hz

The boilers contain all the safety and control units that are specified by the regulations.

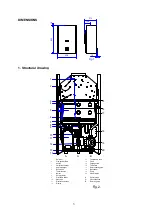

Subassemblies:

•

Brass heat exchanger with oval tubes and bossed lamellas.

•

Two-point control in accordance with the temperature of the room and of the heating water.

The temperature of the delivered water and the maximum temperature are displayed

electronically.

•

Flue-gas backflow sensor wired into the circle of thermoelectric flame safety device, water

temperature monitoring safety limiter thermostat.

•

Double insulated casing