Visual Inspection

Before and after using the chipper/shredder, closely inspect the machine for loose parts

and damage.

⚫

Check the hopper, hopper guard, and funnel for cracks, holes, and loose bolts.

⚫

Check the box frame for cracks or damage.

⚫

Check the entire machine for loose bolts or screws.

⚫

Check the blades for cracks and dings.

⚫

Check the engine oil level.

Cleaning

Clean the machine after each use. Allow the motor to cool and remove the spark plug wire.

Brush off or vacuum wood chips and wipe off the remaining dust from the exterior of the

machine with a dry cloth. DO NOT rinse off the chipper/ shredder with water. Remove any

chips or debris from the hopper and the discharge chute.

It is much harder to clean the machine if you allow it to sit for a while after use. You may

need to use an engine cleaner to remove the built up resins from the motor. Engine

cleaners are available at most auto parts stores.

Maintenance of engine

Spark Plug

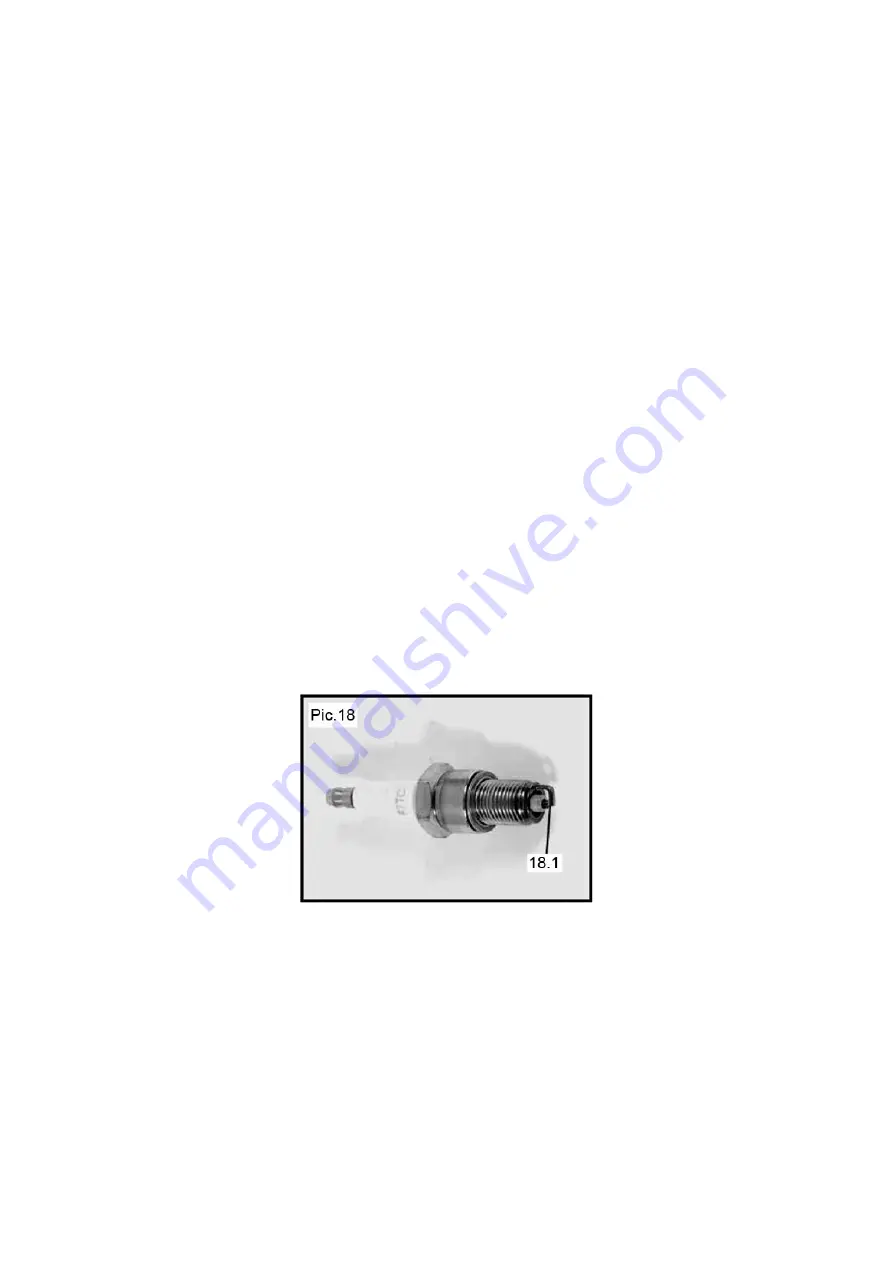

After every 50 hours of running the spark plug should be removed. Check the color of the

deposits on the end of the spark plug it should be a

“Tan” color. Remove all deposits using

a stiff brush a brass wire brush is ideal. Check the spark plug gap (

Pic.18

) (18.1) and adjust

if required. The correct gap should be 0.7 to 0.8mm.

Engine oil replacement

Place the machine on a level surface and warm up the engine for several minutes. Then

stop the engine.

Remove the oil filler cap (

Pic.5

) (5.1).

Place an oil pan under the engine. Remove the oil drain plug (

Pic.5

) (5.2) so that the oil

can be completely drained. You will need to use a tube or other similar device to prevent

the oil leaking onto the frame of the chipper/shredder.

Check the oil drain plug, gasket, oil filler cap and O-ring and if damaged replace.

Reinstall the oil drain plug.

Add engine oil up to the upper level of the dipstick (

Pic.6

) (6.1).