8

/

16

STARTING THE ENGINE

WARNING! Engine delivered without oil and fuel: Fill up with unleaded gasoline and

oil before staring the engine.

a)

Turn engine switch to ON position.(Fig F)

b)

Press the primer button 3 times. (Fig G)

c)

Pull the recoil starter handle gently until it engages the give it a good strong

pull to start the engine. (Fig H)

Fig F Fig G Fig H

TURN THE ENGINE OFF

Turn the engine switch on OFF position, or take out the dustbin.

OPERATIONS

WARNING! Never operate without dustbin; it may be dangerous to your

body.

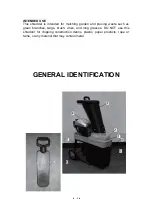

1. TOP HOPPER-FRONT CUT

The large slopping front chute of the top hopper is designed to accept

leaves and small garden clippings. Shredding and mulching is achieved by

natural suction of the debris through the blade chamber. Do not overfeed

and do not feed wet, soggy material into the shredder as this may clog the

blade chamber and the discharge chute. (Fig I)

Engine switch