• Replace worn or damaged parts for safety.

• Store machine in a clean, dry, dark and frost-free place, protected from dust and out of reach of

children. The ideal storage temperature is between 5 and 30°C.

• Use the original packaging to storage whenever possible.

• Cover unit with a suitable protective cover that does not retain moisture. Do not use sheet

plastic as a dust cover. A nonporous cover will trap moisture around the machine, promoting

rust and corrosion.

TRANSPORT

Turn the motor off and disconnect the mains plug. When transporting, be careful not to drop, or

otherwise shock the machine. For transport, the machine has to be fixed against slipping and

tipping over. Do not place objects on the machine.

TROUBLESHOOTING

A CAUTION!

Failures of your machine which require larger interference must always be eliminated by

specialized workshop. Unauthorized interferences can cause damages. If you can not rectify

the fault using the measures described here, contact an authorized service.

SERVICE AND SPARE PARTS _________________________________________________________

•

Have your device serviced by a qualified repair personnel using only identical replacement

parts. This will ensure that the safety of the device is maintained.

•

Whether you need technical advice, repairs, or genuine factory replacement parts, contact

SWAP. Information on service locations, visit

•

When ordering spare parts, please quote the part number, this can be found

at

DISPOSAL

_______________________________________________________________

Electrical products should not be discarded with household products. According to the

European Directive 2012/19/EU on waste electrical and electronic equipment and its

implementation into national law, electrical products used must be collected separately

and disposed of at collection points provided for this purpose. Talk with your local

authorities or dealer for advice on recycling.

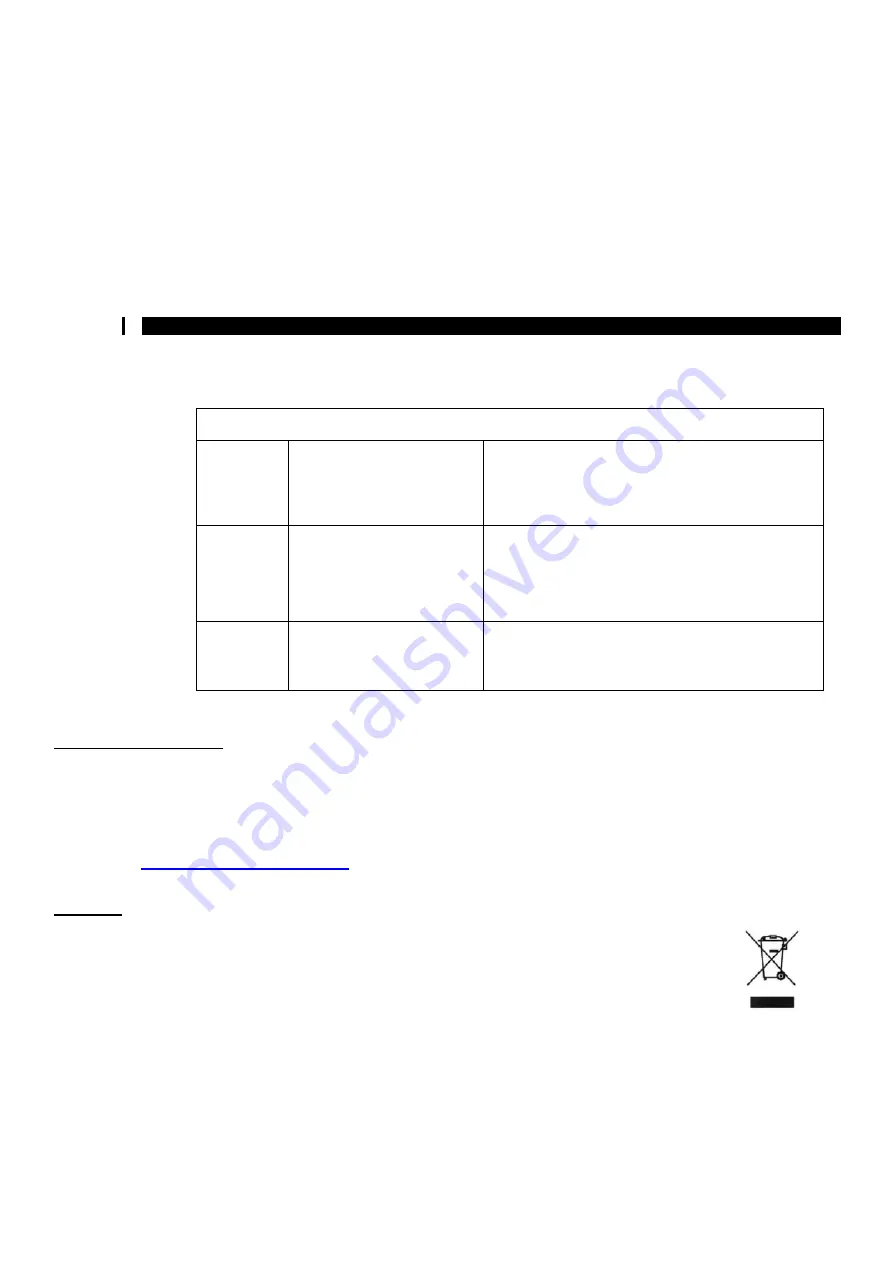

Trouble Possible cause Corrective action

No start

condition

a)

Failure mains power

supply

b)

Loose

electrical

connections

c)

Overheated motor

a)

Check for cause of blown fuse/breaker and

replace or reset

b)

Contact the authorized service center

c)

Let the engine cool

Low

pressure

a)

Air leak in safety valve

b)

Restricted air filter

c)

Defective check valve

a)

Check valve manually by pulling on rings. If

condition persists replace valve by an

authorized service.

b)

Clean or replace as necessary.

c)

Replace check valve by an authorized

service

Safety valve

releasing

a) Defective pressure

switch or improper

adjustment

a) Check for proper adjustment and if

problem persists, replace pressure switch

by an authorized service.

Summary of Contents for FC6LS

Page 5: ......