GB

15

4

、

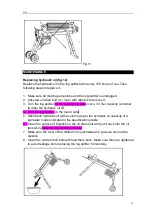

Install the stock support plate. Push the two M8

×

16 screws through mounting hole of the support

plate and the stock support plate, tighten with two M8 nuts. Then push two M8

×

16 screws through

the two mounting hole of the stock support plate, push two M8

×

50 bolts through the mounting hole

of the left and right bent legs and mounting hole of the stock support plate on the other side, tighten

with four M8 nuts. (Fig. 4)

Fig. 4

5

、

After the third step, an entire machine has been assembled

OPERATION

Warning!

Before operating the log splitter, the Bleed Screw (15) Fig. 6, should be

loosened by some rotations until air can go in and out of the oil tank

smoothly.

Air flow through the Bleed Screw hole should be detectable while the log

splitter is under operations.

Before moving the log splitter, make sure the Bleed Screw is tightened to

avoid oil leaking from this point.

Failed to loosen the bleed screw will keep the sealed air in hydraulic system being

compressed after being decompressed, such continuous air compression and

decompression will blow out the seals of the hydraulic system and cause

permanent damage to the log splitter.