19

7. MAINTENANCE

Good maintenance is essential for safe, economical, and trouble-free operation. It will also help

reduce air pollution.

WARNING

Exhaust gas contains poisonous carbon modoxide. Shut off the engine before performing

any maintenance. If the engine must be run, make sure the area is well ventilated.

Periodic maintenance and adjustment is necessary to keep the generator in good operating

condition. Perform the service and inspection at the intervals shown in the Maintenance schedule

below.

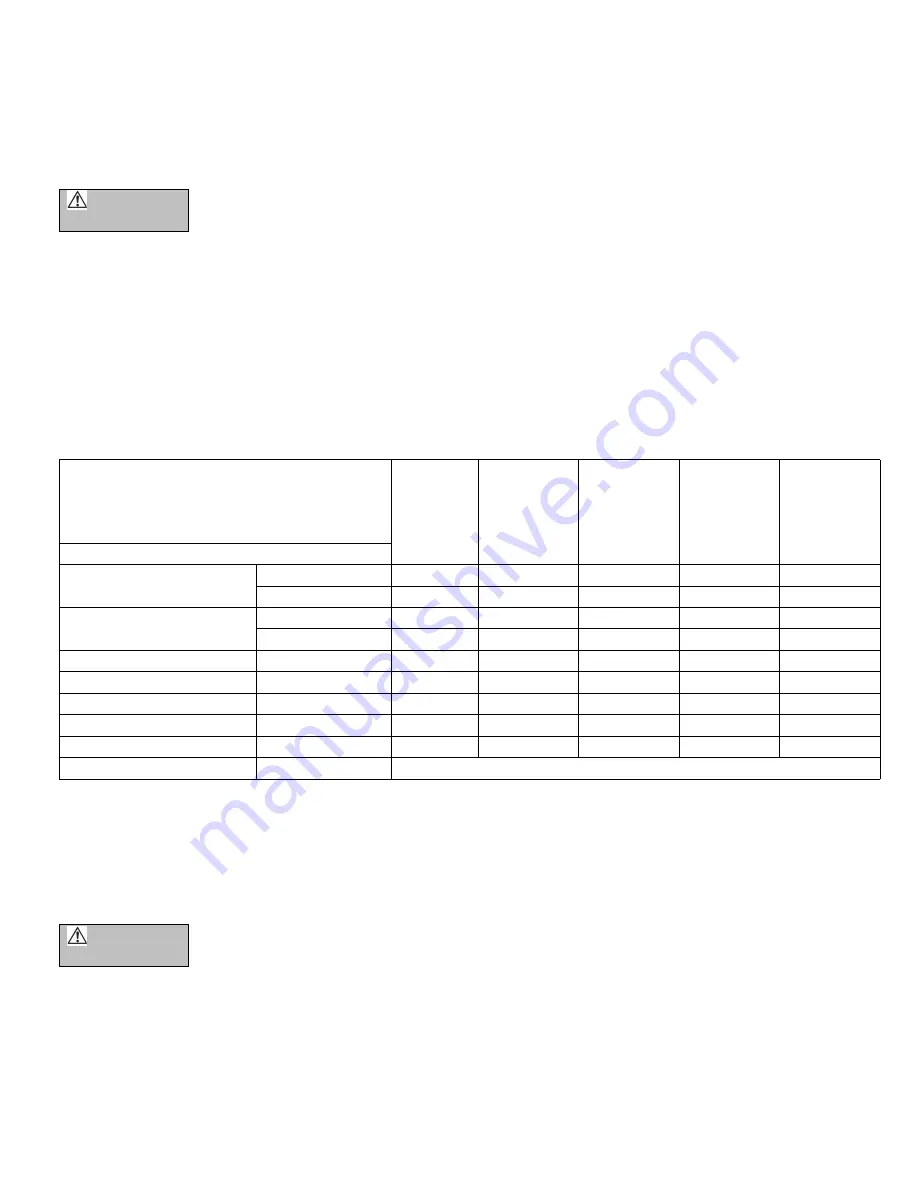

1) MAINTENANCE SCHEDULE

REGULAR SERVICE PERIOD

Performed at every indicated month or

operating hour interval, whichever

comes first.

Each

use

First

month or

20 Hrs.

(3)

Every 3

months or

50 Hrs.

(3)

Every 6

months or

100 Hrs.

(3)

Every

year or

300 Hrs.

(3)

ITEM

Engine oil

Check level

o

Change

o

o

Air cleaner

Check

o

Clean

o(1)

Sediment Cup

Clean

o

Spark plug

Check-Clean

o

Spark arrester

Clean

o

Valve clearance

Check-Adjust

o(2)

Fuel tank and strainer Clean

o(2)

Fuel line

Check

Every 2 years (Replace if necessary) (2)

1) Service more frequently when used in dusty areas.

2) These items should be serviced by an authorized generator dealer, unless the owner has the

proper tools and is mechanically proficient.

(3) For professional commercial use, long hours of operation to determine proper maintenance

intervals.

WARNING

Improper maintenance, or failure to correct a problem before operation, can cause a

malfunction in which you can be seriously hurt or killed. Always follow the inspection and

maintenance recommendations and schedules in this owner's manual.

Summary of Contents for FG4500-1

Page 28: ...28 10 CIRCUIT DIAGRAM...