Maintenance and inspection

1.

Inspecting the tool

When using dull tool bits this can cause motor malfunction and degraded efficiency.

Always replace dull bits with new ones without delay when abrasion is noted.

2.

Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that they are properly tightened.

Should any of the screws be loose, retighten them immediately. Failure to do so could

result in serious injury.

3.

Maintenance of the motor.

The motor unit winding is the very “heart” of the power tool. Exercise due care to ensure

the winding does not become damaged and/or wet with oil or water.

4.

Inspecting the carbon brushes.

Two carbon bushes are provided.

The motor employs carbon brushes that are consumable parts; when an excessively

worn carbon brush could result in motor trouble, replace the carbon brush. The carbon

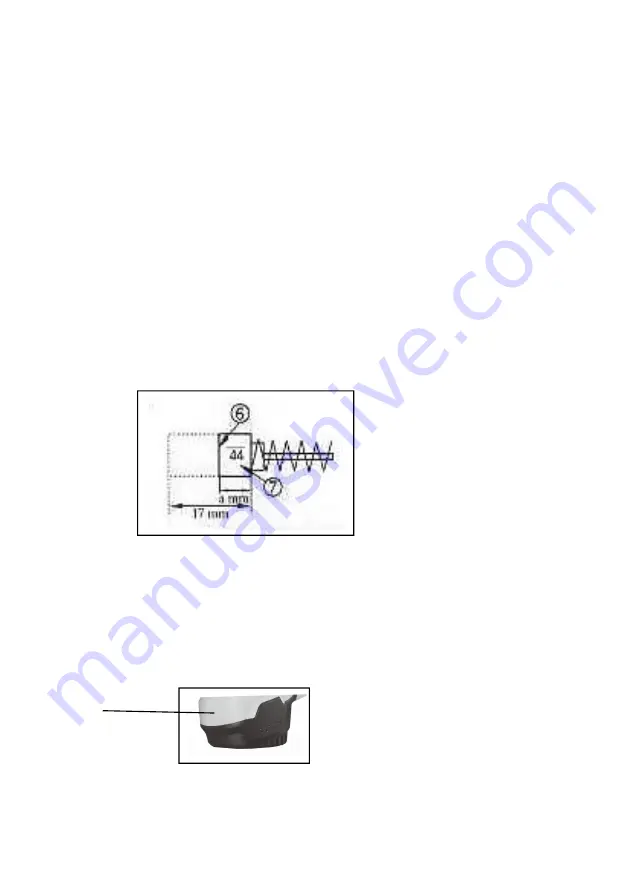

brushes must be only replaced by a qualified service. Wear limiter (6) No of carbon brush

(7). (See Fig 7)

Fig 7

Always keep carbon brushes clean and ensure that they slide freely within the brush

holders.

Replacement

The carbon brush can be removed by removing the cap cover (9), cap rubber and brush

cap in that order at the interior

(See Fig 8)

brush

carton

Fig 8

To replace carbon brush, reverse order of removal.

11