Setting the Operating Mode

The operating mode of the power tool is selected with the mode selector switch.

Note:

Change the operating mode only when the machine is switched off! Otherwise, the machine can be

damaged.

To change the operating mode, push the release button and turn the mode selector switch to the requested

position until it can be heard to latch.

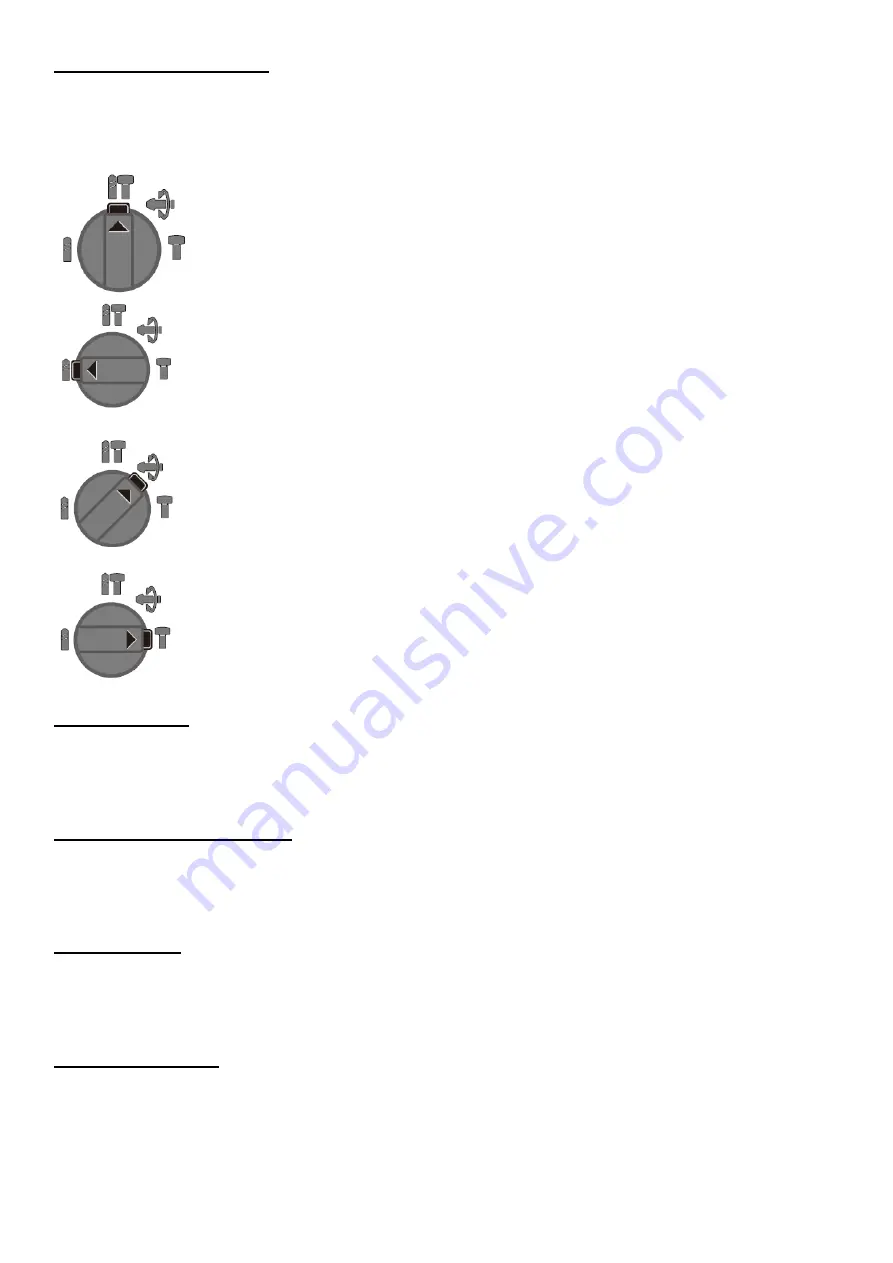

Position for

hammer drilling

in concrete or stone

Position for

drilling

without impact in wood, metal, ceramic and plastic as well as for

screwdriving and thread cutting

Vario-Lock

position for adjustment of the chiseling position

The mode selector switch does not latch in this position.

Position for

chiseling

Sense of rotation

The direction of rotation switch is used to change the direction of rotation of the machine. Switch off and

unlock the ON/OFF switch before changing the direction of rotation.

Clockwise rotation:

press the right rotation switch (forward arrow)

Counter-clockwise rotation:

press the left rotation switch (backward arrow)

Setting the Speed/Impact Rate

The speed/impact rate of the switched-on power tool can be variably adjusted, depending on how far the

ON/OFF switch is pressed.

Light pressure on the ON/OFF switch results in low speed/impact rate. Further pressure on the switch

increases the speed/impact rate.

Overload Clutch

If the tool insert becomes caught or jammed, the drive to the drill spindle is interrupted. Because of the

forces that occur always hold the power tool firmly with both hands and provide for a secure stance.

If the power tool jams, switch the machine off and loosen the tool insert. When switching the power tool on

with the drilling tool jammed, high reaction torques can occur.

Working Instructions

The chisel can be locked in 36 positions. In this manner, the optimum working position can be set for each

application.

Insert the chisel into the tool holder.

Turn

the mode selector switch to the “Vario-lock” position (See “setting the operating mode”). Turn the tool

holder to the desired chiseling position.

Turn the mode selector switch to the chiseling position, the tool holder is now locked.

For chiseling, set the rotation direction to right rotation.

Summary of Contents for FMP800-CL

Page 14: ......

Page 15: ......

Page 16: ...BUILDER SAS 32 rue Aristide Berg s ZI 31270 Cugnaux France Made in PRC 2022...