10

3. OPERATING INSTRUCTIONS

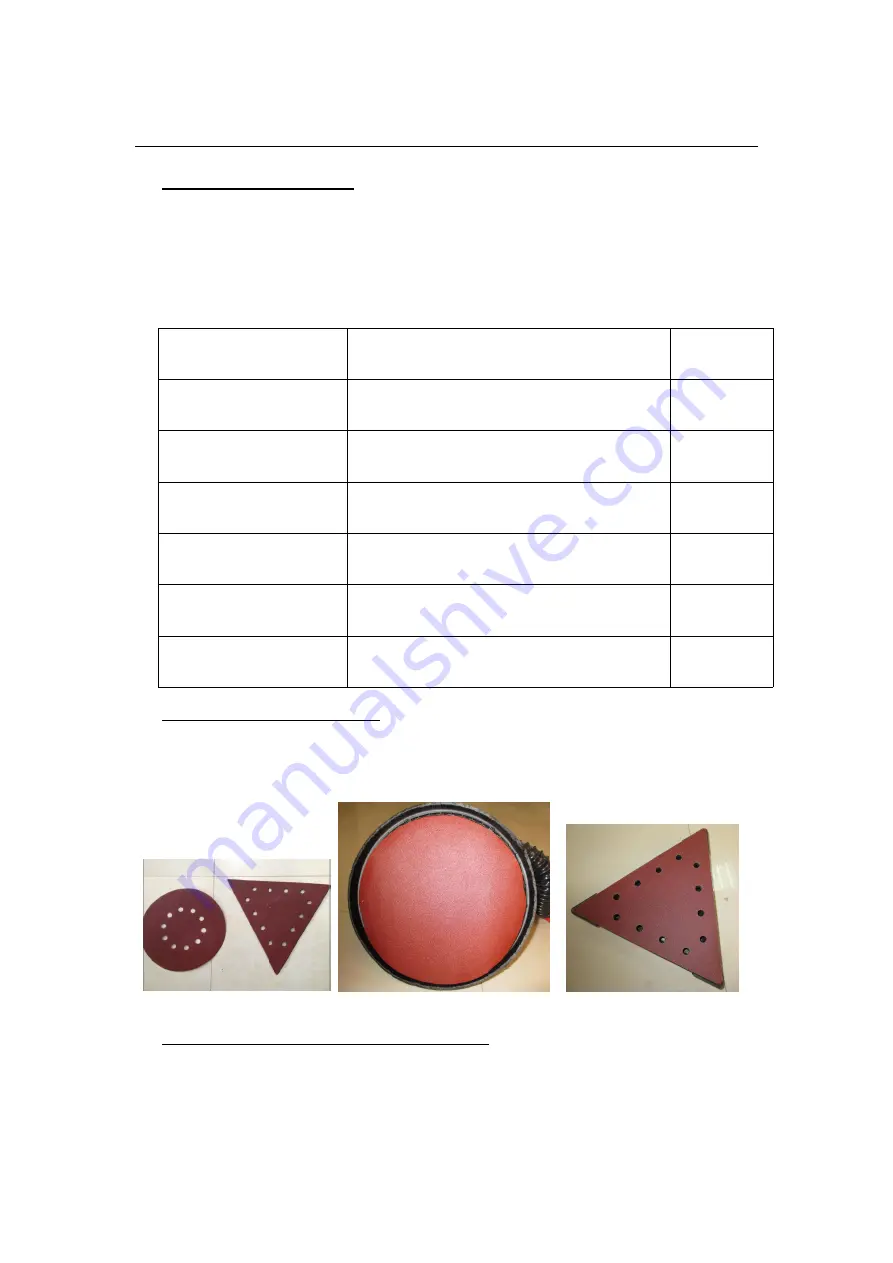

a. Selection of the sandpaper

The drywall sander is equipped with 6 pcs of sanding paper (80/100/120/150/180/240).

This abrasive is suitable for most applications. 120 and 240 abrasive discs are available

for works requiring a smoother finish.

According to the material and grinding effect, choose the appropriate sandpaper.

Material

Usage

Sandpaper

Pigment

Removal of pigment layer

40

Paint

Removal of paint

60

Filling agent

Sanding pigment (such as finishing bottom)

80

Interstitial material

Removal of pickling, sanding residues

100

Pigment layer drips and

convex surface

Removal brushing marks

120

Flat bottom material

Good finished sanding for new painting

180-240

b. Replacement of sanding paper

Before installing the new paper, the wheel must be clear from dirt. Clean it by using a

brush. The surface of the adhesive disc has a lint layer that can quickly and easily be

installed flocking self-adhesive sandpaper. The sandpaper surface has to be pressed on

the adhesive disc.

c. Installation of the pad (sanding and delta pad)

Push the two locking device localized on the side of the bracket. If already installed,

remove the current pad by turning it a little. Install the pad and release the locking device.

Check if the pad is well installed.