24

2

)

storage

●

The following steps should be taken to prepare the machine for storage.

1. Empty the fuel tank after use in the last quarter.

a

)

Empty the fuel tank with a suction pump.

Be careful! Do not discharge gasoline in a closed room or near an open flame. do not smoke! This can cause an explosion or fire.

b

)

Start the engine and let it run until it runs out of all remaining gasoline.

c

)

Remove the spark plug. Approximately 20 ml of oil was injected into the combustion chamber using a syringe. Pull the starter disk to

evenly distribute the oil in the combustion chamber.

2. Clean and lubricate the machine carefully as described in the Lubrication Instructions above.

3. Gently apply the rust inhibitor to the impeller and exposed metal parts to avoid corrosion.

4. Store the machine in a dry, clean, frost-proof place away from unauthorized personnel

Be careful! The engine must be completely cooled before storing the machine.

Machine maintenance instructions

1

)

The importance of proper maintenance

●

Proper maintenance is critical to safe, economical and

trouble-free operation; it also helps reduce air pollution.

Improper maintenance or failure to correct problems prior to

operation can result in serious injury or death.

●

Always follow the maintenance recommendations and

schedules in this instruction manual.

To help you properly maintain your machine, the following pages

include maintenance plans, routine inspection procedures, and simple

maintenance procedures using basic hand tools. Other maintenance

tasks that are more difficult or require special tools are best handled by

professionals, usually by our technical staff or other qualified

mechanics.

The maintenance plan is for normal operating conditions. If you

operate the machine under harsh conditions, such as continuous high

load or high temperature operation, or in unusually humid

temperatures, consult your service dealer for advice that is appropriate

for your individual needs and use.

Maintenance, replacement or repair of the emission control

devices and systems can be performed by any engine service

facility or individual using components that meet the EPA

standards in the "Certification".

2

)

Maintenance safety

We cannot warn you of the dangers that can arise when performing

maintenance. Only you can decide if you should perform the given

situation.

3

)

Safety instructions

●

Make sure the engine is off before starting any maintenance or

repairs.

4

)

Routine maintenance

1.

Oil maintenance

Before each use of the machine, check the oil level to see if it is between the upper and lower scales of the oil gauge (see Fig 39-2).

。

The new

machine is run for 4 hours before use to achieve the best effect of the machine. After the running-in period, please replace the oil. The oil should be

replaced after 25 hours of use, and the oil should be changed periodically according to the instructions.

The oil change should be carried out after the engine is in the heat engine. Do not add too much oil, otherwise it will appear: black smoke, no

power (excessive cylinder carbon deposit, small spark plug clearance). Engine overheating. Filling the engine oil should not be too small, otherwise it

will appear: the engine gear is noisy, the piston ring accelerates wear and damage, and even the piston jams, causing serious damage to the engine.

When changing the oil, the machine must be tilted in the direction of the oil port, you can pour it out and replace it with new oil, but you can't tilt it to

the other side. Otherwise, the oil will flow into the carburetor, causing damage to the carburetor.

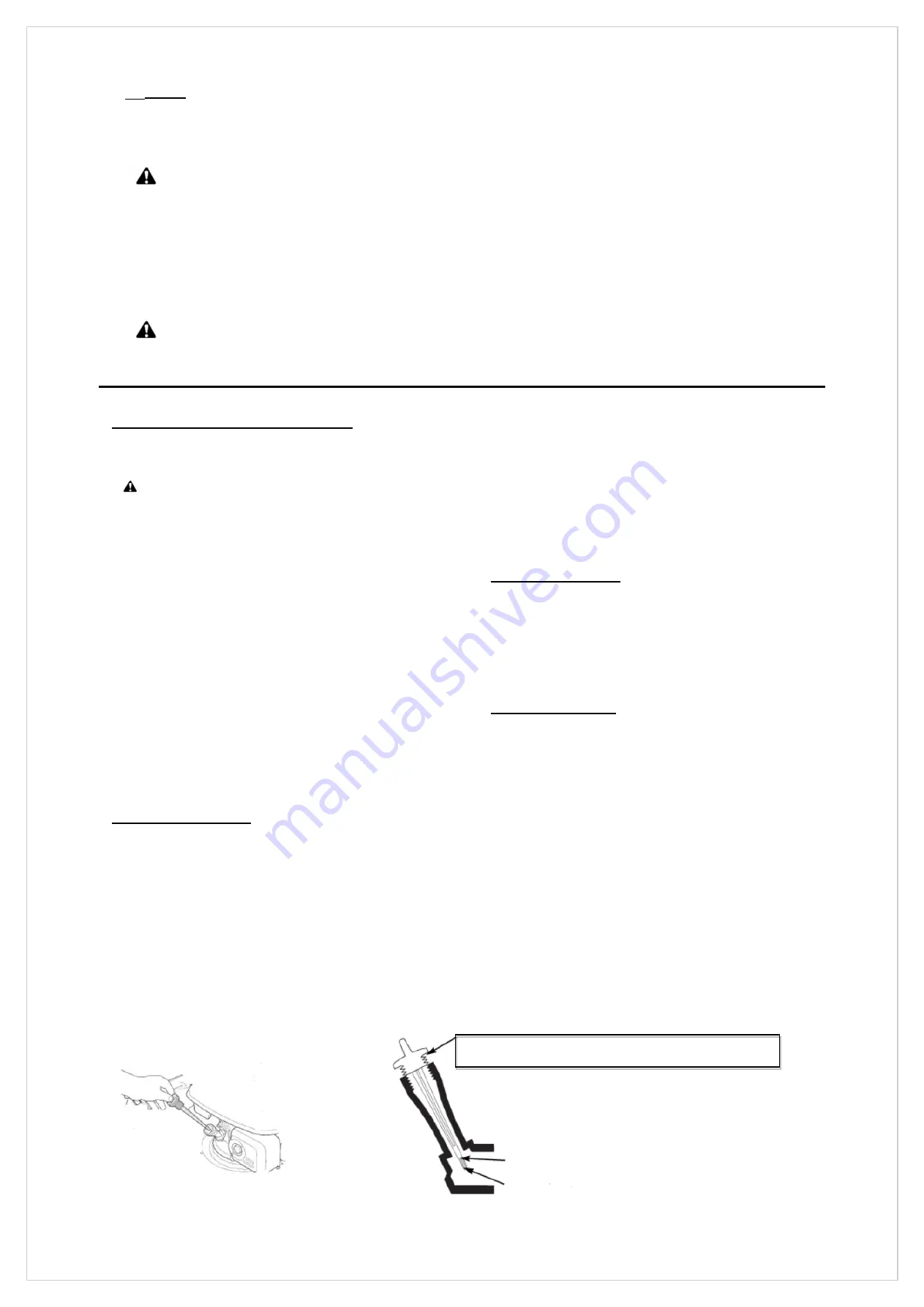

Fig.

39-1 Take out the dipstick

Fig.

39-2 Measuring oil level

Upper limit of oil level

Lower limit of oil level

Do not screw in the dipstick when checking the oil level