36

en

Overload temperature

If only reduced power is available when the motor is

started in LOW, the temperature sensor is defective. If

this occurs several times, contact the customer service.

PRCD personal protection switch (*)

(see page 14)

The PRCD personal protection switch is specifically for

your protection; therefore, do

not

misuse it as on

On/Off switch.

If the PRCD personal protection switch is damaged, e.g.

due to contact with water, do not use it any more.

The PRCD personal protection switch is indispensable;

it is used for protection of the power tool operator

against electric shock. Under fault-free operation, the

control lamp of the PRCD personal protection switch

lights up.

Check the operability of the PRCD personal protection

switch before beginning to work:

1. Connect the plug of the PRCD personal protection

switch with the mains socket outlet.

2. Press the RESET–button. The indication light on the

PRCD personal protection switch lights up.

3. Disconnect the plug from the socket outlet. The indi-

cation light goes out.

4. Repeat steps 1. and 2.

5. Press the TEST–button; the indication light goes out.

If the indication light does not go out, do not run the

machine. In this case, contact the customer service.

6. Press the RESET–button; when the indication light

lights up, the machine can now be switched on.

Do not use the PRCD personal protection switch for

switching the power tool on and off.

Repair and customer service.

When working metal under extreme oper-

ating conditions, it is possible for conductive

dust to settle in the interior of the power

tool. The total insulation of the power tool can be

impaired. Blow out the interior of the power tool via

the ventilation slots frequently with dry and oil-free

compressed air.

Renew stickers and warning indications on the power

tool when aged and worn.

After several hours of operation, the play in the dove-

tail guide can increase. As a consequence, the drill

motor can glide alongside the dove-tail guide by itself.

In this case, retighten all set screws of the dove-tail

guide correspondingly so that the drilling motor can

easily be moved manually, yet does not glide by itself

(see page 20).

Products that have come into contact with asbestos

may not be sent in for repair. Dispose of products con-

taminated with asbestos according to the applicable

country-specific regulations for such disposal.

When the machine's power supply cord is damaged, it

must be replaced by the manufacturer or their repre-

sentative.

The current spares parts list for this power tool can be

found on our website at www.fein.com.

Use only original spare parts.

If required, you can change the following parts your-

self:

Application tools, coolant container, contact protector

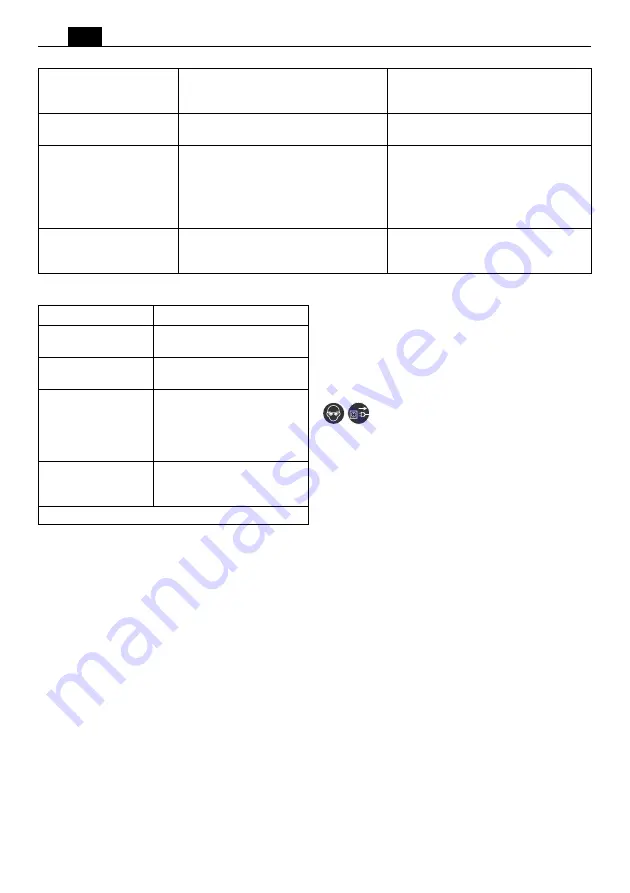

Error message/

Response of magnet signal

lamp

Meaning

Corrective Action

Indicator lights up green

Magnetic holding power possibly suffi-

cient.

Indicator flashes (1 Hz)

Magnetic holding power possibly insuffi-

cient.

Even when working on steel materials

where the material thickness is below

12 mm, the work piece must be made

thicker with an additional steel plate in

order to ensure the magnetic holding

power.

Indicator flashes (5 Hz)

–

Magnet defective

–

Incorrect mains voltage

–

Motor temperature too high

–

Repair magnet

–

Ensure correct mains voltage

–

Allow motor to cool down

Temperature range

Meaning

Temperature > Tg1

Cooling speed very low, with-

out cooling capacity

Temperature < Tg1

Motor switches off and can be

restarted

Temperature > Tg2

Motor switches off, indicator

flashes at 5 Hz;

Motor must cool down below

Tg2 before restarting is possi-

ble

Temperature

between Tg1 and

Tg2

Cooling speed without cool-

ing capacity

Tg1, Tg2: Limit temperatures

Summary of Contents for 72706061000

Page 1: ...KBU 110 4 M 7 270 7 273 ...

Page 3: ...3 7 17 19 23 14 9 11 12 6 8 13 4 5 8 19 20 22 6 9 10 15 16 17 18 ...

Page 4: ...4 3 1 2 max 500 ml max 17 US fl oz ...

Page 5: ...5 1 3 2 5 4 max 500 ml max 17 US fl oz ...

Page 6: ...6 6 mm 4 1 4 2 5 5 3 3 2 1 1 50 mm 100 mm 2 2 3 ...

Page 7: ...7 3 5 5 3 5 4 1 2 4 1 3 2 MK 4 MT 4 CM 4 ...

Page 8: ...8 3 5 6 4 7 7 4 2 3 1 1 3 5 mm 6 mm ...

Page 9: ...9 0 mm 0 mm ...

Page 10: ...10 12 mm 12 mm ...

Page 11: ...11 5 mm 6 mm 1 5 3 2 4 4 3x2 ...

Page 12: ...12 5 mm 5 0 2 Nm 6 mm 6 6 3x2 5 7 ...

Page 13: ...13 2 1 ...

Page 14: ...14 ...

Page 15: ...15 1 2 ...

Page 16: ...16 2 1 ...

Page 17: ...17 ...

Page 19: ...19 30 mm ...

Page 20: ...20 2 5 mm ...

Page 21: ...21 2 5 mm ...

Page 22: ...22 2 5 mm ...