5

en

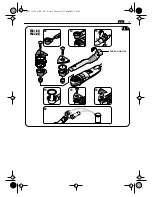

Special safety instructions.

This double-insulated power tool is equipped

with a polarized plug (one contact is wider than

the other). The plug will only fit into the polar-

ized socket outlet in one position. Turn the plug

if it does not fit completely into the socket out-

let. If the plug still does not fit, have a qualified

electrician install a polarized socket outlet. Do

not modify or alter the plug under any circum-

stances.

Double-insulated power tools nei-

ther require a three-core power cable nor a

power connection with ground contact.

Operate the power tool only off of power sup-

plies whose voltage and frequency values cor-

respond with the values on the type plate of the

power tool.

When operating the power tool in a damp envi-

ronment, it must be connected via a ground-

fault circuit interrupter (g.f.c.i.).

Using special

rubber protective gloves and footwear

increase your own safety.

Use clamps or another practical way to secure

and support the workpiece to a stable platform.

Holding the work by hand or against your

body leaves it unstable and may lead to loss of

control.

Before mounting or replacing application tools

or accessories, pull the power plug.

This pre-

ventive safety measure rules out the danger of

injuries through accidental starting of the

power tool.

Hold the power tool by the insulated gripping

surfaces when performing operations where

the application tool could contact hidden wir-

ing or its own power cord.

Contact with a

“live” wire will also make exposed metal

parts of the power tool “live” and shock the

operator.

Use appropriate detectors to determine if utility

lines are hidden in the work area or call the

local utility company for assistance.

Contact

with electric lines can lead to fire and electric

shock. Damaging a gas line can lead to explo-

sion. Penetrating a water line causes property

damage or may cause an electric shock.

Do not direct the power tool against yourself,

other persons or animals.

Danger of injury

from sharp or hot application tools.

For all work or when changing application

tools, always wear protective gloves.

Danger

of injury from the sharp edges of the applica-

tion tools. Application tools can become very

hot while working. Danger of burns!

Grasp the power tool in such a safe manner

that your body never comes into contact with

the application tool, especially while working

with application tools such as saw blades or

other blades pointed toward the grasping

range.

Touching sharp tips or cutting edges

can lead to injuries.

The power tool is not permitted for operations

or working with water supply.

Water penetrat-

ing the motor casing can lead to electric

shock.

Do not rivet or screw any name-plates or signs

onto the power tool.

If the insulation is dam-

aged, protection against an electric shock will

be ineffective. Adhesive labels are recom-

mended.

Clean the ventilation openings on the power

tool at regular intervals. The motor blower

draws dust into the housing.

An excessive

accumulation of metallic dust can cause an

electrical hazard.

3 41 01 120 21 0.book Seite 5 Dienstag, 26. Mai 2009 2:21 14