17

EN

Do not carry the power tool at your side while the motor is

running.

Accidental contact with the rotating accessory

could cause it to snag your clothing, pulling the accessory

into your body.

Causes of kick-back and precautionary measures for

the operator.

Kick-back is a sudden reaction of the power tool to a

pinched or snagged rotating wheel, backing pad, brush or

other accessory.

Pinching or snagging causes rapid stalling of the rotating

accessory, which in turn causes the uncontrolled power

tool to be forced in the direction opposite to the acces-

sory’s rotation at the point of the binding.

For example, if an abrasive wheel is snagged or pinched

by the workpiece, the edge of the wheel entering into

the pinch point can dig into the surface of the material,

causing the wheel to climb out or kick out.

The wheel may either jump towards or away from the

operator, depending on the direction of the wheel’s rota-

tion at the point of pinching and can possibly also break.

Kickback is the result of power tool misuse and/or incor-

rect operating procedures or conditions and can be

avoided by taking the proper precautions listed below.

Hold the power tool firmly and position your body and arms

optimally to withstand any kickback forces. Always use the

original auxiliary handle so that kickback forces or the

starting torque can be mastered in the best possible way.

The operator can master the starting torque and kickback

forces if suitable precautionary measures are taken.

Never place your hand near the rotating accessory.

The

accessory may kick back over your hand.

Do not position your body in the area where the power tool

will move if kickback occurs.

Kickback will propel the

power tool in the direction opposite to the wheel’s

movement at the point of snagging.

Take special care when machining corners, sharp edges,

etc. Prevent the accessory from bouncing off or tilting.

Cor-

ners, sharp edges or bouncing have a tendency to snag

the rotating accessory and cause loss of control or kick-

back.

Do not attach a saw chain, wood-carving blade or circular

saw blade.

Blades of this kind cause frequent kickback or

loss of control over the power tool.

Additional safety instructions, particularly for

cutting operations

Avoid jamming the cutting wheel or applying excessive

pressure. Do not attempt to make an excessive depth of cut.

Overstressing the wheel increases the loading and sus-

ceptibility to twisting or binding in the cut and the likeli-

hood of kickback or wheel breakage.

Do not position yourself in line with and behind the rotating

cutting wheel.

When the cutting wheel, at the point of

operation, is moving away from your body, a possible

kickback may propel the cutting wheel and power tool

directly at you.

Switch the power tool off if the cutting wheel blocks or if

the cutting process is interrupted for some reason. Hold the

power tool motionless until the cutting wheel has come to

a complete stop. Never attempt to remove the cutting wheel

from the cut while the wheel is still moving, otherwise kick-

back may occur.

Investigate and take corrective action to

eliminate the cause of the wheel binding.

Do not restart the cutting operation if the cutting wheel is

in the workpiece. Let the cutting wheel reach full speed and

then carefully reenter the cut.

The cutting wheel may bind,

jump out or kick back if the power tool is restarted with

the cutting wheel in the workpiece.

Support the panels or any oversized workpiece to minimize

the risk of wheel pinching or kickback.

Large workpieces

tend to sag under their own weight. Supports must be

placed under the workpiece near the line of cut on both

sides of the cutting wheel and at the ends of the work-

piece.

Use extra caution during “plunge cuts" in walls or other

blind areas.

The penetrating cutting wheel may cut gas or

water conduits, electrical wiring or objects that could

cause kickback.

Safety instructions, particularly for sanding work

with a sanding disc.

When sanding, do not use an excessively oversized sanding

disc. Follow the manufacturer’s recommendations when

selecting sanding discs.

Sanding discs larger than the

backing pad present a laceration hazard; they can tear,

cause snagging, rip off from the backing pad or cause

kickback.

Special safety instructions for sanding work with

wire brushes.

Be aware that wire bristles are thrown by the brush even

during normal operation. Do not overstress the wire bristles

by applying excessive load to the brush.

The wire bristles

can easily penetrate light clothing and/or the skin.

If the use of a guard is stipulated for sanding with wire

brushes, do not allow the wire bristles to contact the guard.

The wire brush may expand in diameter due to the work

load and centrifugal forces.

Before putting into operation, check the mains connection

and the mains plug for damage.

The value of the estimated weighted acceleration

obtained in the laboratory can serve for predicting the

exposure to vibration. During work, weighted accelera-

tions will be dependent on the particular application, and

deviation from this laboratory value can occur.

Intended use of the power tool:

hand-guided angle grinder for commercial use, for dry-

sanding/grinding and cutting metal and stone in weather-

protected environments using the application tools and

accessories recommended by FEIN.

This machine is also intended to be powered by a.c. gen-

erators with sufficient power output that correspond

with ISO 8528, design class G2. Compliance with this

Standard in particular is not given when the so-called dis-

tortion factor exceeds 10%. When in doubt, inform

yourself about the generator in use.

3 41 01 088 06 0.book Seite 17 Dienstag, 13. November 2007 3:20 15

Summary of Contents for WSG14-125

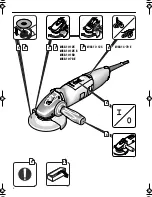

Page 3: ...3 5 6 4 7 7 8 8 4 10 9 WSG 14 125 WSG 14 125 S WSG 14 150 WSG 14 70 E WSS 14 125 WSG 14 70 E...

Page 4: ...4 2 3 2 1 WSG 14 125 S WSG 14 150 WSG 14 70 E 1 4...

Page 6: ...6 2 3 1 2 1 3 WSS 14 125 WSS 14 125...

Page 7: ...7 2 2 WSS 14 125 WSG 14 125 1 3 WSG 14 125 S WSG 14 150 WSG 14 70 E 1 3...

Page 9: ...9 20 40...

Page 40: ...40 EL 3 41 30 054 06 1...

Page 41: ...41 EL To...

Page 42: ...42 EL FEIN ISO 8528 G2 10 5 6 Service WSS 14 Service FEIN FEIN FEIN H FEIN...

Page 76: ...76 RU 3 41 30 054 06 1...

Page 77: ...77 RU...

Page 78: ...78 RU FEIN 8528 G2 10 1 5 6 WSS 14 FEIN...

Page 79: ...79 RU FEIN FEIN FEIN...