FEIN - Repair - Tools

Alle Rechte bei FEIN, insbesondere für den Fall der Schutzrechtanmeldung.

Jede Verfügungsbefugnis wie Kopieren und Weitergabe liegt bei FEIN.

MVK

04 / 08

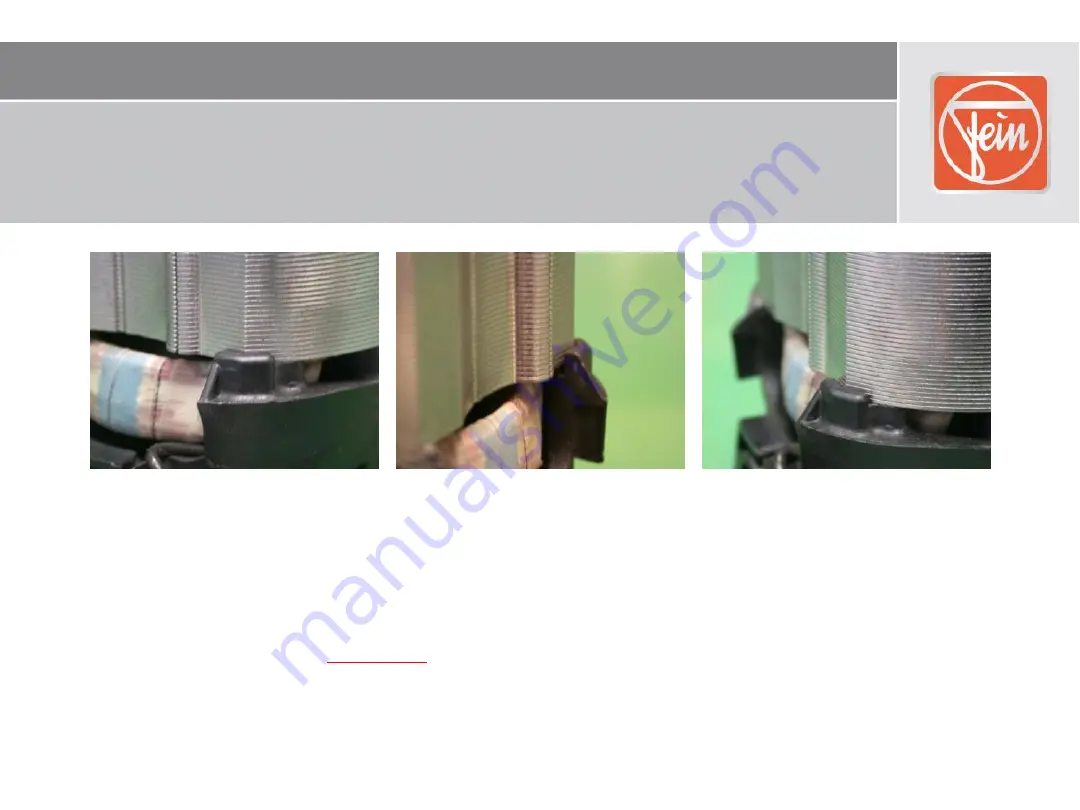

If the field coil unit is correct assembled, there is no air gap between the edge guide

and the field coil. The field coil must touch the plastic cover and has to be tighten.

If this is the reason for a machine failure, the field coil unit has to be changed

at all hazards.

A new adjustment is

impossible

.

7. Special information