59

Planer-Thicknesser

A 941 / AD 941 / AD 951

11.4 Faults, causes and repairs

Fault

Cause

Repair

Machine does not start

Main switch at setting „0“

Check switch position

Emergency stop switch engaged

Unlock the Emergency stop button

Planer tables and/or vacuum hood incor-

rectly positioned (Safety break switch is

not activated)

Close planer tables properly and position

the vacuum hood correctly

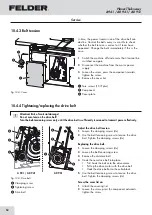

Squeaking noises when start-

ing up

Insufficient tension (Drive belt)

Retensioning the drive belt

The joint is not true (extremely

splayed or open joint)

Receiver-side of the planer table is mis-

aligned

Adjusting the joint

Replace the planer knives*1)

Planer knives are worn out

Replace the planer knives*1)

When surface planing, work-

piece stops at the receiver-side

of the planer table

Receiver-side of the planer table is too

high in relation to the circle of cut

Adjusting the joint

Replace the planer knives*1)

„Straight cut“ at the end of the

workpiece when surface plan-

ing

Receiver-side of the planer table is too

low in relation to the circle of cut

Adjusting the joint

Replace the planer knives*1)

The planer fence angle is not

correct

Angle setting misadjusted

Correcting the angle of the planing fence

Unsatisfactory planing result

Planer knives are worn out

Replace the planer knives*1)

„Straight cut“ at the beginning

of the workpiece when thick-

ness planing

Insufficient spring pressure on the feeder-

side (corrugated) feed roller

Adjusting the feed rollers*2)

„Straight cut“ at the end of the

workpiece when thickness

planing

Insufficient spring pressure on the

extraction-side (smooth) feed roller

Adjusting the feed rollers*2)

„Oblique cut“ at the beginning

of the workpiece when thick-

ness planing

Insufficient spring pressure on one side of

the feeder-side (corrugated) feed roller

Adjusting the feed rollers*2)

„Oblique cut“ at the end of the

workpiece when thickness

planing

Outfeed roller (smooth) spring pressure

too low on one side

Adjusting the feed rollers*2)

Electrical height adjustment is

not running

The motor safety switch has been trigge-

red

Cleaning the height guides, lubricating

the height spindle/engage motor safety

switch

*1) System planer knives: Reverse or replace

Standard planer knives: Sharpen or replace

Adjusting the joint

*2) Contact service technician

Faults

Summary of Contents for AD 941

Page 13: ...13 Planer Thicknesser A 941 AD 941 AD 951 Safety...

Page 67: ...67 Planer Thicknesser A 941 AD 941 AD 951 Faults...

Page 69: ...69 Planer Thicknesser A 941 AD 941 AD 951 Annex...

Page 70: ......

Page 71: ......