27

"

#

!

!

#

#

!

"

Bandsaw

FB 540/640/740/840/940

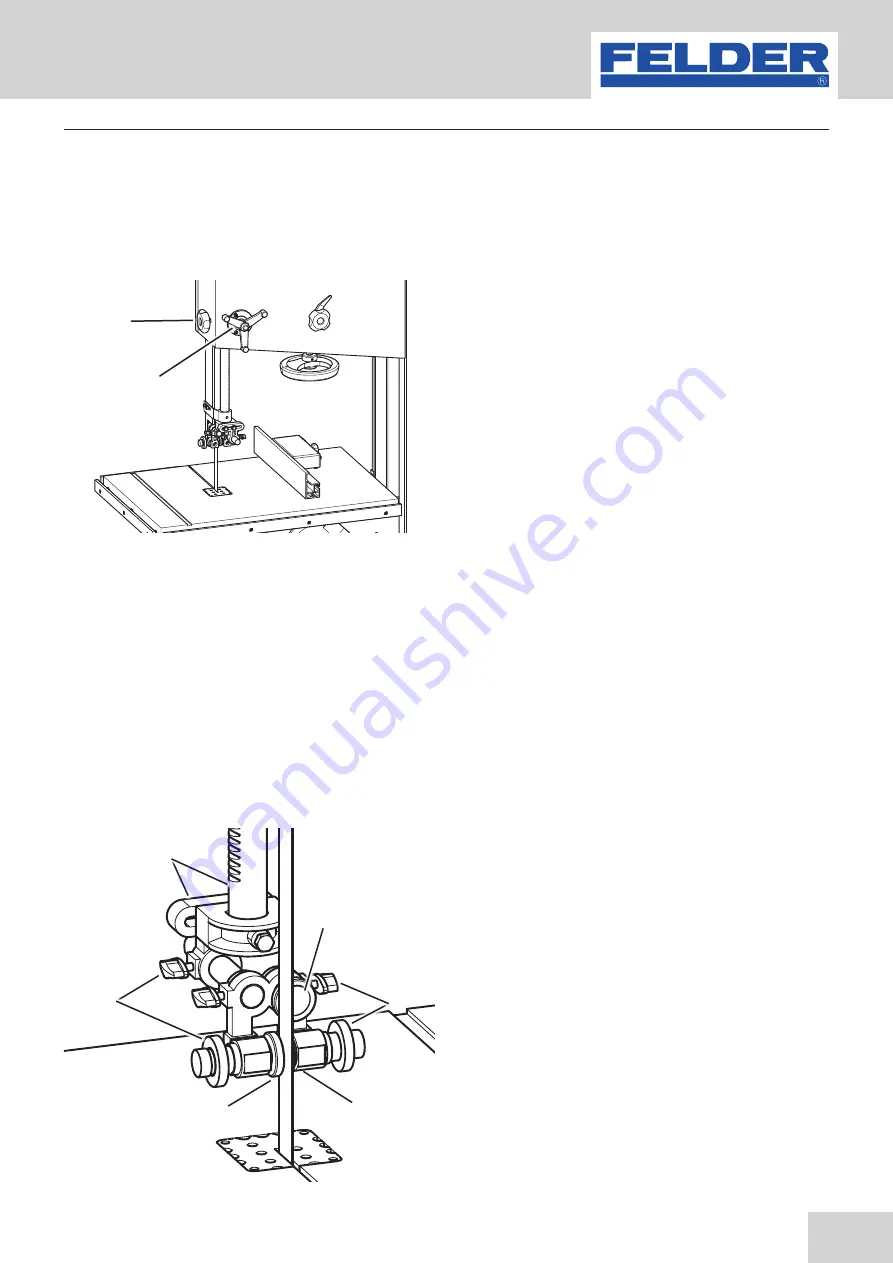

7.4.3 Setting the saw blade guides

The upper saw belt guide has to be lowered as closely

as possible to the workpiece (5-10 mm).

To set the height, open the clamping screw and turn

the handwheel until the desired height is achieved and

clamp the clamping screw again tightly.

This adjustment may not be executed whilst the machine

is in operation!

The side guide rollers should graze the saw belt slightly

to ensure a vibration-free and straight cut. The position

of these rollers can be adjusted with the adjusting screws

and then clamped with the locking ring. The guide rollers

should be positioned approx. 2 mm behind the saw belt

teeth.

The rear support roller prevents strong pushing back of

the saw blade during the cut and should be clamped 1-2

mm behind the band saw blade after opening the clam-

ping screw.

Fig. 20: Bearings

Fig. 21: Saw blade guide

7.4.3.1 Height adjustable protection device

!

Clamping screws

"

Blade guide height adjustment

7.4.3.2 Saw blade guide upper/down

• If the lower saw belt guide is also a ball bearing mo-

del, the same installation instructions are applicable

as for the upper saw belt guide.

• The fixed saw belt guide is comprised of a base

with 2 screwed in wooden pads. The wooden pads

should graze the saw belt slightly to guarantee a

vibration-free and straight cut.

!

Bearings

"

Support roller

#

Clamping screws

Operation

Summary of Contents for FB 540

Page 5: ...5 Bandsaw FB 540 640 740 840 940 Table of Contents...

Page 40: ...40 Bandsaw FB 540 640 740 840 940 11 Spare parts Spare parts...

Page 41: ...41 Bandsaw FB 540 640 740 840 940 Spare parts...

Page 42: ...42 Bandsaw FB 540 640 740 840 940 Spare parts...

Page 43: ...43 Bandsaw FB 540 640 740 840 940 Spare parts...

Page 44: ...44 Bandsaw FB 540 640 740 840 940 Spare parts...