74

A

B

!

"

!

"

#

#

$

$

%

Panel Saw

K3 basic/K3 winner/K3 e-classic

Faults

11.7 Aligning the sliding table ball cage

The ball cage can, over time, become misaligned due

to small sliding table travelling distances. The full cutting

length will, thus, not be achieved.

Repair:

1.

Move the sliding table past the resistance into the

dead-centre position and up to the stop.

2.

Then, move the sliding table continuously in the other

direction to the dead-centre position and up to the stop.

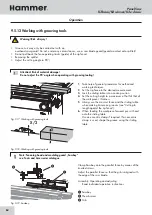

11.6 Adjusting/correcting the parallel cutting fence angle

Required tools

• 2 Spanners 13 mm

Fig. 11-2: Check the parallel cutting fence guide angle

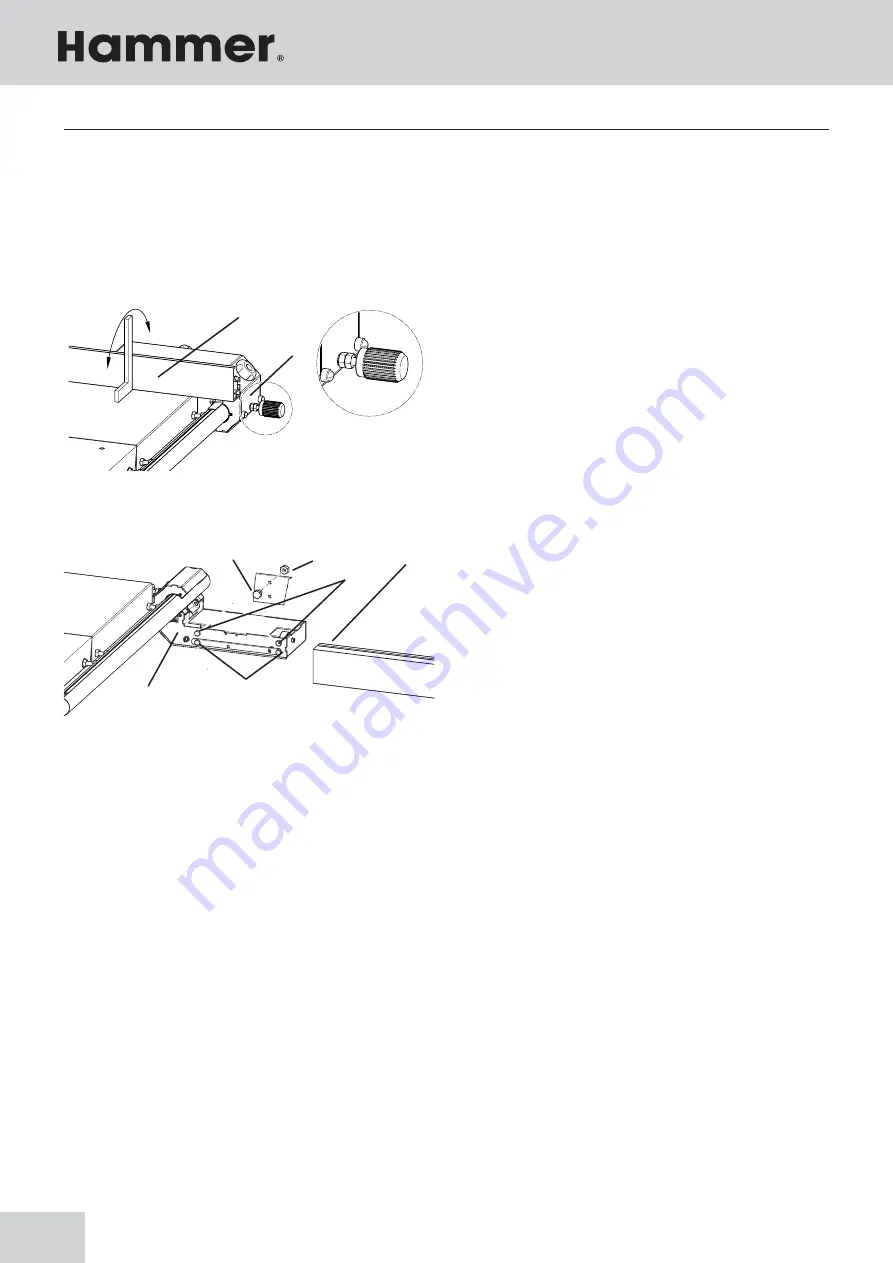

Fig. 11-3: Readjust the parallel cutting fence guide angle

only possible with: K3 winner

1.

Switch the machine off and ensure that it cannot be

switched on again.

2.

Check the guide angle and readjust if required.

3.

Remove the guide.

4.

Pivot the parallel cutting fence outwards.

5.

Adjusting in the „A“ direction:

• Hold the screw tight with the spanner.

• Loosen the inner nut with a spanner.

• Unscrew the screw by half a turn.

• Tighten the inner nut.

6.

Adjusting in the „B“ direction:

• Hold the screw tight with the spanner.

• Loosen the inner nut with a spanner.

• Unscrew the screw by half a turn.

• Tighten the inner nut.

7.

Assemble the guide.

8.

Pivot the parallel cutting fence back.

9.

Check the adjustment of the angle with a bevelled

steel square and readjust if required.

!

Guide

"

Rip fence

#

Screw - Adjusting in the „A“ direction

$

Screw - Adjusting in the „B“ direction

%

Nut