6

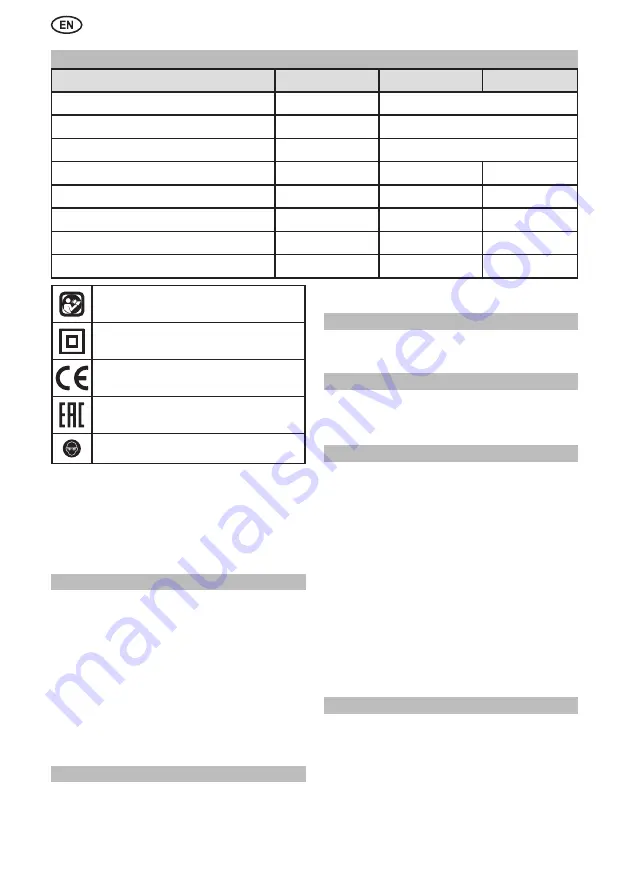

TECHNICAL DATA

Read the operating instructions

Protection category II power tool; double

insulated

In accordance with essential applicable safety

standards of European directives

In accordance with essential applicable safety

standards of Russian Federation

Wear eye protection

Follow very carefully the instructions in this manual,

save it and keep it close at hand, ready to carry out any

inspection of parts that may be necessary.

If the tool is used with care and normal maintenance is

carried out, it will work well for a long time.

The functions and use of the tool you have bought

shall be only those described in this manual.

Any other

use of the tool is strictly forbidden.

ILLUSTRATIONS

DESCRIPTION (See figures)

1 Start-up switch (Fig.1)

2 Auxiliary handle (Fig.1)

3 Disc guard for sanding operation (Fig.1)

4 Disc guard for cutting-off operations (Fig.1)

5 Spindle (shaft) (Fig.1)

6 Spindle blocking button (Fig.1)

7 Support plate (Fig.1)

8 Abrasive disc (Fig.1)

9 Clamping nut (Fig.1)

10 Pin spanner (Fig.1)

11 Clamping plate (Fig.1)

12 Screw (Fig.1)

13 Screw (Fig.1)

EQUIPMENT

- Disc guard (for sanding operation)

- 1 auxiliary handle

- 1 pin spanner

- Disc clamping nuts

- Operating instructions with Safety instructions

- Warranty

BRIEF DESCRIPTION

This angle grinder has been designed for cutting,

deburring and cutting metals and stone without the use of

water.

BEFORE USING THIS TOOL

Before using the tool, make sure the mains voltage

is correct: it must be the same as that on the specification

label. Machines with 230V can also be connected to a

220V mains supply.

FITTING SAFETY DEVICES

WARNING!

Always unplug the machine before

carrying out work on it.

1. Fitting the disc guard

To change the disc guard unscrew 4 screws

12

and

13

from clamping plate of guard

11

, take off the guard, place

another guard, place the clamping plate matching holes of

the guard and of the clamping plate, tight screws.

The guard can be rotated around the spindle. For this:

- loosen the screw

13

of the guard;

- rotate the guard in the position excluding spark

emission in direction of operator;

- tight the screw

13

.

WARNING!

The closed part of the disc guard should

always point towards the user.

2. Fitting the auxiliary handle

2

Use of the auxiliary handle is obligatory in order to

ensure greater control and safety when handling the tool.

The auxiliary handle

2

must be screwed on to the right or

left side, depending on the type of work to be carried out.

FITTING THE ACCESSORIES (DISCS AND WHEELS)

WARNING!

For safety reasons, the machine should

always be unplugged from the mains before changing the

disc or wheel. Always work with the guard on and wear

safety goggles.

Use deburring and cutting discs with fibre-reinforced

synthetic binders, for a max. peripheral speed of 80 m/s

and cup wheels with synthetic binder for 45 m/s. Protect

discs and wheels from knocks and blows.

WARNING!

Never press the blocking button when

the machine is running. The shaft must have stopped com-

Angle grinder

AG115/1000

AG125/1000

Voltage

V~

230

Frequency

Hz

50-60

Input power

W

1010

No-load speed

min

-1

11000

11000

Max. disc diameter

mm

115

125

Inner disc diameter

mm

22.2

22.2

Spindle thread

ISO

M14

M14

Weight according EPTA-Procedure 01/2003

kg

2.4

2.45

Summary of Contents for AG125/1000

Page 1: ...AG115 1000 AG125 1000 WINKELSCHLEIFER...

Page 2: ...2 Fig 1 11 12 13 12 13...

Page 36: ...36 1 b 2 b d f 3 b d f g 4 b...

Page 37: ...37 d f g 5 a b c d e f g 1 h i j k...

Page 38: ...38 l m n o p a b c d e a b c d e a b c...

Page 39: ...39 d e f a a a b...

Page 42: ...42 4 12 13 11 11 180 13 2 2 3 6 S17 7 9 10 14 80 45 4 2 0 220 1 9 30 40...

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......