5

Read the operating instructions

Protection category II power tool; double

insulated

Wear eye, ear protection

Follow very carefully the instructions in this manual,

save it and keep it close at hand, ready to carry out any

inspection of parts that may be necessary.

If the tool is used with care and normal maintenance is

carried out, it will work well for a long time.

The functions and use of the tool you have bought

shall be only those described in this manual.

Any other

use of the tool is strictly forbidden.

ILLUSTRATIONS

DESCRIPTION (See figures)

A SDS-plus chuck (Fig.1)

B Chuck sliding ring (Fig.1)

C Speed regulating handwheel (Fig.1)

D Push button for mode change (Fig.1)

E Mode changeover(Fig.1)

F Label for reversing rotation R-L (Fig.1)

G Changeover left/right direction switch (Fig.1)

H On-/off switch (Fig.1)

I Locking button (Fig.1)

K Depth stop fixing wing nut (Fig.1)

L Depth gauge (Fig.1)

M Auxiliary handle (Fig.1)

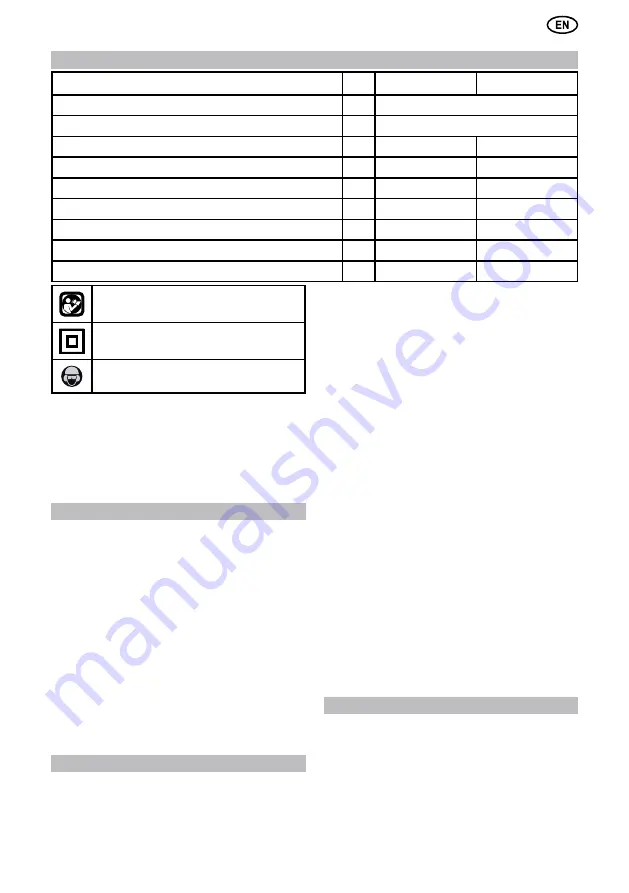

N Screwdriver bit (accessory*) (Fig.2)

O Key chuck (accessory*) (Fig.2)

P SDS-plus adapter (accessory*) (Fig.2)

* Not included in standard equipment, available as an

accessory

BRIEF DESCRIPTION

A percussion unit generates the power necessary for

hammer drilling or chiselling in masonry.

Just like when we hit a conventional chisel with

hammer, a free piston strikes the bit or chisel, which can

move lengthways, through an intermediate part. This free

TECHNICAL DATA

piston is driven by a second piston activated by an electric

motor through an air cushion. This electro-pneumatic

principle offers great percussion elasticity and work free

from recoil.

Unlike a normal hammer drill, the drilling capacity

does not depend on the pressure exerted on the machine.

Use of the tool: The rotary hammer can be used

for hammer drilling and drilling in wood, metal as well as

plastic, and also for driving screws with driving bits installed

in a key chuck with the SDS-plus adapter. Any other use

not mentioned is not allowed.

Additional features of the rotary hammer:

- The machine is equipped with a safety clutch or

mechanism which operates when a bit seizes up, pro-

tecting the user and the machine’s electro-mechanical

parts. The clutch is released automatically.

WARNING!

This machine must not be used with hole

saws, core bits, diamond bits, etc, as they tend to jam in

the hole easily. This would cause the safety clutch to trip

out too often.

- Percussion drill chuck

A

with SDS–plus mounting for

using tools with SDS-plus shaft. A geared drill chuck or a

keyless chuck can be used in conjunction with the SDS-

Plus Adapter

P

.

- Change direction of rotation with switch lever

G

–due

to a lockout mechanism, switching the lever is only possi-

ble if the On/Off switch

H

is not depressed.

- Electronic control of spindle speed, infinitely variable

by finger pressure on the On/Off switch

H

.

- For maximum speed regulation use handwheel

C

.

- For continuous operation the On/Off switch can be

locked in the “On” position by the button

I

.

- Auxiliary handle

M

, adjustable, with integral depth

gauge

L

.

BEFORE USING THIS TOOL

WARNING!

Before carrying out any work, check, for

instance, using a metal detector, that there are no electric

wires or gas or water pipes under the surfaces you wish to

work on.

Make sure the mains voltage is correct: it must be

the same as that on the specification label. Machines with

230V can also be connected to a 220V mains supply.

To turn the machine on, press the ON/OFF switch

H

and keep it pressed down.

When the ON/OFF switch is released, the machine

Rotary hammer

RH24/700ER

RH30/900ER

Rated voltage

V~

230

Rated frequency

Hz

50

Rated power

W

720

900

No load speed

/min

0-1240

0-1050

No load hammer rate

min

0-5080

0-5100

Drilling diameter in concrete

mm

24

30

Drilling diameter in steel

mm

13

13

Drilling diameter in wood

mm

24

30

Weight according EPTA-Procedure 01/2003

kg

2.9

3.3

Summary of Contents for RH24/700ER

Page 2: ...2 K L A B M D E F C H G I ...

Page 39: ......