14

•

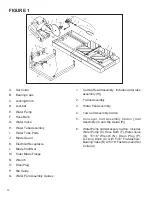

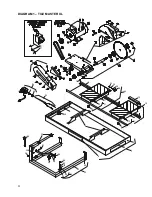

Mount the water pan assembly Guides (Q) over the

Frame Assembly (2) legs between the vertical post and

the Sliding Pan Stop (R). The Pan Assembly (3) should

slide freely back and forth on the Guides (Q) with little

lateral movement. Adjust if needed.

•

Install the Cart Assembly (4) with the Back Stop at the

operating end. Check that all four wheels are on the

rails and that it travels freely back and forth.

Install the Cutting Head Assembly (1):

1.

Set the Cutting Head Assembly (1) on the pivot

bar up against the Set Collar (A). The set collar

has been pre-set at the factory to align the blade

with the slot in the center of the cart; it can be

adjusted if needed.

2.

Install the two Bearing Caps (B) over the long

setscrews located in the bottom of the Cutting Head

(1) using 5/16" flatwashers and locknuts. Next,

tighten the locknuts so that the Cutting Head (1) is

held securely on the base pivot bar, but can be

adjusted up or down.

3.

Insert the Locking Knob (C) with 5/16" flatwasher

through the slotted Lockbar (D) into the tapped

hole in the belt guard. This is used to set the

cutting depth of the blade.

Water Pump Assembly (5) Set-up:

1.

Remove the Water Pump (E), Hose Barb (F), the

Water Control Valve (G) and Water Tube Assem-

bly (H) from their carton. Thread the Hose Barb

(F) on the water pump outlet, hand tighten.

2.

Slide the Control Valve (G) onto the flexible plastic

tubing and push the open end onto the Hose Barb

(F).

3.

Set the Water Pump Assembly (5) in the deep

end of the pan beneath the belt guard.

Note:

The

water pump inlet screen must be submerged

in order to properly pick up water.

4.

Place the Water Tube Assembly (H) to the back

of the Blade Guard (J) and insert the two 1/4"

plastic nozzles into the Ports (I) on the side of the

Blade Guard (J). To prevent interference with the

full movement of the cart, it is recommended that

the tubing and electrical cord exit out the back

through the indented area of the pan.

5.

Insert the male plug into the Receptacle (K) on

the motor. The Water Pump (E) will start when

the motor is turned on. For dry cutting, the water

pump should be unplugged or removed to prevent

damage to the pump.

Install the Cutting Blade:

Always set the Motor Switch to OFF prior to

mounting the blade.

1.

Be sure you are using the correct blade for the

material being cut. For example, blades are avail-

able for cutting materials such as wall tile, quarry

tile, marble, slate and similarly hard materials. For

the best results, always use genuine

FELKER ®

diamond blades. Contact your nearest dealer to

select the correct blade for your specific cutting

needs.

2.

Rotate the Blade Guard (J) fully up, tightening the

wing nut if needed to hold it in the fully raised

position.

3.

Remove the Blade Shaft Nut (L) and the Outer

Blade Flange (M).

4.

Check the blade for Counter Clockwise rotation

(CCW) and install on the spindle shaft.

Rotation direction is indicated by an arrow on

one side of the blade. Make sure the blade

contact surfaces are clean.

5.

Install the outer flange with the large diameter

against the blade. Tighten the Blade Shaft Nut (L)

with the 15/16" Wrench (N) provided.

6.

Lower the Blade Guard (J) and retighten the wing

nut to securely hold the guard in place.

•

Install the Drain Plug (O) into the back end of the pan

and fill with clean water until inlet filter of water pump is

covered; about 12 gal. (46.1 l).

•

Adjust the Pan Assembly (3) to accommodate the size

of the tile to be cut and to obtain the most comfortable

position for the operator.

1.

When cutting smaller tile units, adjust the pan all

the way to the rear. The operator has full view

and control of the work with minimum stretching.

2.

For cutting intermediate sized units, such as 8" or

10" tile, the pan can be placed somewhere between

the maximum forward and maximum rear positions.

3.

When cutting larger units, the pan should be moved

to the maximum forward position, thus giving the

operator the best and most comfortable position, even

when cutting 18" x 18" or larger units.

WARNING: Read the Operating Procedure

completely before operating your tile saw.

Take into account the working conditions from

the health and safety point of view.

Always pay extreme care and attention to the

preparation of the machine before starting.

Remove all wrenches and tools from the

machine.

Always keeps blade guard in place.

•

Fill the Pan with enough water to fully submerge the

water pump screen. It takes approximately 12 gallons

(46.1 l.) to fill the Pan.

•

Before connecting the power cord:

*

Check the spindle nut to be sure it is tight and that

the blade rotates freely.

4

OPERATING PROCEDURE

Summary of Contents for TILE MASTER XL TM1-XLHT

Page 2: ...2...

Page 7: ...7 NOTES...

Page 30: ...30 Diagram 2 Wiring Diagram 193042 1 5HP HT 115V 60 1...

Page 31: ...31 Diagram 3 Wiring Diagram 000605 1 5HP 115V 208 230 60 1...

Page 32: ...32 Diagram 4 Wiring Diagram 000607 2 HP 240 50 1...

Page 34: ...34 NOTES...

Page 35: ...35...