15

WARNING: Check that the ON/OFF switch is in

the OFF position. Then connect the power cord

to a properly grounded outlet of the correct

voltage. See the decal near the power cord for

power requirements. If needed, use the correct

size three (3) conductor extension cord to avoid

excessive voltage drop. Never use lamp cord

type extensions. Refer to the Recommended

Extension Cords chart below.

•

Turn the switch to

ON

. The blade should turn counter-

clockwise, when looking at the blade guard side. The

water pump will start automatically when the motor

starts. Adjustment of the water supply may be made

by means of the Control Valve (G).

•

Follow the blade manufacturer’s recommendations for

dry or wet cutting. Wet cutting blades can be damaged

or destroyed without sufficient water. Only blades

specifically designed for dry cutting can be used

without coolant.

The water supply should be adequate, with

water flowing on both sides of the blade. Keep

the water clean and make certain the WATER

LEVER IS ALWAYS ABOVE THE PUMP INLET.

Do not run the water pump dry!! Unplug for

dry cutting.

•

For straight cuts, position the tile squarely against the

back edge of the conveyor cart. Keep the cart clean

and free of cuttings. The standard rip guide is used.

•

Move the conveyor cart slowly and carefully until the

blade is in contact with the tile. The blade needs a

chance to “break-in” or “wear-in” slightly. It may take

about ten cuts to open a new blade for best cutting.

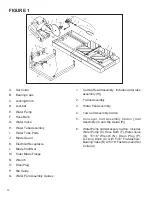

Your

Tile Master XL

tile saw is factory assembled and aligned

prior to shipment to ensure accurate cuts when your saw is

delivered. However, since

FELKER®

cannot control rough

handling during shipping, it is suggested that the alignment

be checked. If the saw is found in need of adjustment, refer

to the appropriate section(s) below.

There are two basic alignment checks for the

Tile Master

XL

and any adjustments made must follow these procedures

to ensure that the unit functions freely.

Adjustment tools required: Carpenter’s Square, two (2) 7/16"

wrenches, 1/2" wrench and 5/32" hex key.

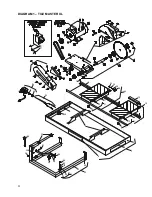

1.

Check the Blade in Slot Alignment

*

The blade should be centered in the conveyor cart

slot.

*

Set-up your saw as described above and move

the conveyor cart back and forth from the front to

the rear of the pan. If the blade contacts either

side of the slot, the Cutting Head Location

Adjustment must be performed.

Cutting Head Location Adjustment (See Figure)

*

The Cutting Head Assembly is located between to

Set Collars (S). Using a 5/32" hex key, loosen

these two (2) set collars. Next, loosen the four (4)

5/16"-18 locknut nuts (1/2" wrench) that clamp

the bearing caps (B) to the Pivot Bar (T). Move

the Head Assembly along the bar until the blade

no longer contacts the slot. Re-locate the set

collars against the sides of the Cutting Head again

and retighten the set screws. Retighten the

locknuts on the bearing caps.

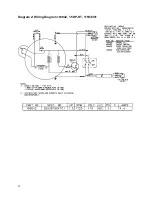

Good motor performance depends on proper

voltage. Extension cords that are too long and/

or too small in wire gauge reduce the voltage

to the motor under load. Use extension cords

no smaller than indicated below.

2.

Check the Parallel Alignment (See Figure)

*

The conveyor cart should travel parallel to the plane

of the blade.

*

Place a square rule against the backstop, lightly

in contact with the blade. The blade surface should

be parallel to the square; i.e., no gap between the

blade and the square at either the front or back

edge of the blade. Next, holding the square firmly,

The motor is equipped with a manual overload protection

reset button. If the motors overheats, the red reset button

will “pop out” to open the motor circuit; stopping the motor

and water pump. If this occurs , the motor ON/OFF switch

must be set to OFF. After the motor cools, push in the reset

button. When it stays in, the motor can be restarted.

7

ALIGNMENT PROCEDURES

5

MANUAL THERMAL OVERLOAD

6

RECOMMENDED EXTENSION CORDS

MOTOR F.L. AMPS 50' Cord

75' Cord 100' Cord

HP

RPM

115V 230V 115V 230V 115V 230V 115V 230V

1-1/2 1725 14.6

#12

#10

#8

1-1/2 3450 17.2

8.6

#10 #14 #10 #14

#8

#14

2

2850

12

#12

#10

#10

Summary of Contents for TILE MASTER XL TM1-XLHT

Page 2: ...2...

Page 7: ...7 NOTES...

Page 30: ...30 Diagram 2 Wiring Diagram 193042 1 5HP HT 115V 60 1...

Page 31: ...31 Diagram 3 Wiring Diagram 000605 1 5HP 115V 208 230 60 1...

Page 32: ...32 Diagram 4 Wiring Diagram 000607 2 HP 240 50 1...

Page 34: ...34 NOTES...

Page 35: ...35...