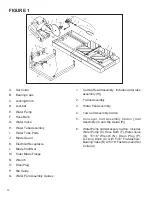

16

Before performing any maintenance, ALWAYS

place the machine on a level surface with the

motor OFF and disconnect the electrical

current. Let the machine cool down!!

Your

FELKER®

tile saw is a ruggedly constructed machine,

engineered to give long, satisfactory performance. Simple

daily maintenance and care will add to the life and productivity

of your saw.

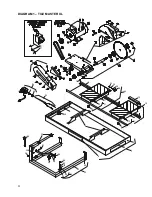

traverse the cart fore and aft. The blade should

remain parallel to the square, staying slightly in

contact with it throughout its full travel. If the blade

does not stay in contact with the square, the

Parallel alignment must be performed.

Parallel Alignment

*

The parallel tracking of the cart can be adjusted

by moving the rails on which the cart travels. The

mounting holes in the pan and the Rail Support

(U) are slotted to accommodate this adjustment.

*

Align the inside rail first. Loosen the four (8)

1/4"-20 fasteners (7/16" wrenches) locating the

two (2) Rails (R) so that both rails are free to move.

Move the end(s) of rail until the square is flush

with the blade as described above. Tighten the

fasteners of this rail and recheck the alignment.

Once alignment has been made, move the cart

fore and aft to locate the second rail parallel to

the first. Tighten the remaining fasteners.

The

Tile Master XL

is designed for use with a

FELKER®

6"

Profile Wheel, such as P/N 621081 or 621082.

•

Raise the blade guard. Remove the spindle nut and

outer flange. Remove the tile saw blade if one has

been installed.

•

Install the profile wheel onto the spindle shaft up against

the inner flange with the working surface to the outside.

•

Secure into place by reversing the outer flange and

tightening the spindle nut. Lower the Blade Guard (J)

back down over the profile wheel.

•

Locate the material for profiling:

1.

Set the edge of the part to be shaped parallel to

the wheel.

2.

Locate the material under the wheel. Pull the

Conveyor Cart (4) with the material from under

the wheel to set proper cutting height.

3.

Loosen the Locking Knob (C) and lower the Cutting

Head (1) so that the wheel just slightly makes

contact with the material.

4.

Secure the Cutting Head (1) into position with the

Locking Knob (C) for cutting.

5.

Note:

Profiling usually takes several light passes

to produce the best results. Set lower each time

until the desire depth has been reached.

After each day’s use:

CLEAN THE MACHINE!!

*

Turn off and unplug the saw before performing

any maintenance.

*

Keep the cart top clean and free for cuttings. To

clean it, flush the top surface and grooves with

water.

*

Drain, clean and refill the pan frequently. Flush

the coolant system with plenty of water, then drain

and refill the pan.

*

If the water flow stops, check the water pump to

see if the shaft and impeller turn freely. See the

WATER PUMP

TROUBLE-SHOOTING

PROCEDURE

section.

*

It is always good practice to clean your tile saw

after each day’s use. Drain the water and clean

out the pan. Clean the rails. Before storing, it is

good practice to wipe or spray rails with

water-soluble oil (like, WD-40 or equivalent).

Entrust all repairs to your authorized dealer

only.

If Water Stops Flowing

,

1. Stop Sawing

, then

2. Disconnect Electrical Plug from Outlet

, then

3. Remove the Pump

, then

4. Back Flush.

Back flushing is done by forcing water into the pump dis-

charge and out through the screen. Most of the time this

procedure works, and the pump can be put back into ser-

vice. (See Figure below)

If the back flushing does not work, remove the screen and

turn the impeller manually, looking for and rinsing out the

impeller cavity of any dirt or foreign matter.

8

PROFILE WHEEL SET-UP AND USE

9

MAINTENANCE PROCEDURES

10

WATER PUMP TROUBLE-SHOOTING PROCEDURE

Summary of Contents for TILE MASTER XL TM1-XLHT

Page 2: ...2...

Page 7: ...7 NOTES...

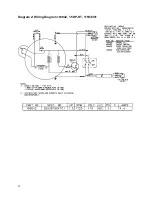

Page 30: ...30 Diagram 2 Wiring Diagram 193042 1 5HP HT 115V 60 1...

Page 31: ...31 Diagram 3 Wiring Diagram 000605 1 5HP 115V 208 230 60 1...

Page 32: ...32 Diagram 4 Wiring Diagram 000607 2 HP 240 50 1...

Page 34: ...34 NOTES...

Page 35: ...35...