3

PRODUCT MAINTENANCE

All cross-cut shredders require oil for peak performance.

If not oiled, a machine may experience diminished

sheet capacity, intrusive noise when shredding and could

ultimately stop running. To avoid these problems, we

recommend you oil your shredder each time you empty

your waste bin.

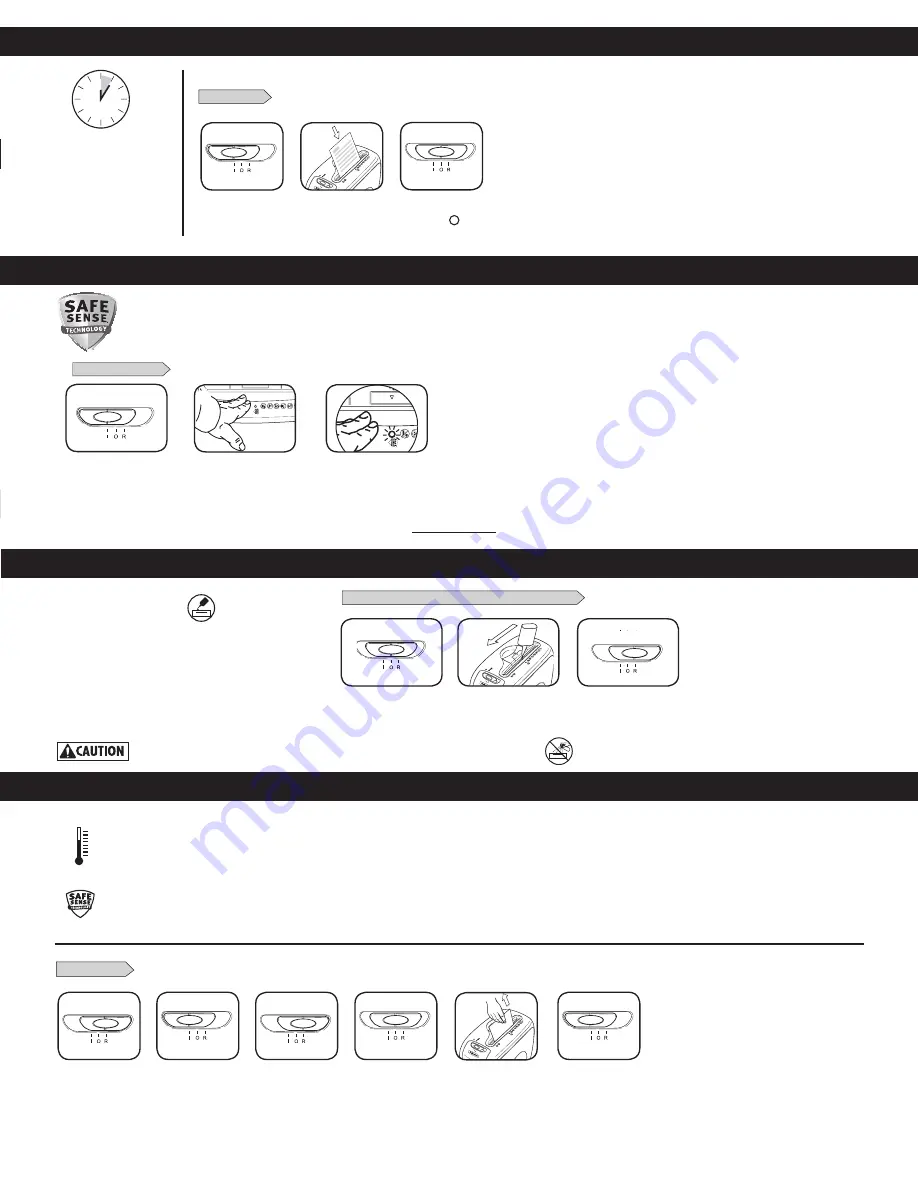

OILING SHREDDER

PAPER/CARD

BASIC SHREDDING OPERATION

Continuous operation:

Up to 5 minutes maximum

NOTE:

Shredder runs briefly

after each pass to clear entry.

Continuous operation beyond

5-minutes will trigger

20-minute cool down period.

PAPER JAM

ADVANCED PRODUCT FEATURES

SAFESENSE

®

TECHNOLOGY OPERATION

Stops shredding immediately when hands touch the paper opening.

SET-UP AND TESTING

TROUBLESHOOTING

Press Auto-On (I)

Touch test area and

look for the SafeSense

®

indicator to illuminate

SafeSense

®

is active and

working properly

*Only use a non-aerosol vegetable oil in long nozzle container such as Fellowes 35250

FOLLOW OILING PROCEDURE BELOW AND REPEAT TWICE

Set to Reverse (R)

2-3 seconds

* Apply oil

across entry

Set to Off (O)

M-12C

2

1

3

1

M-12C

2

3

M-12C

5

3

2

1

4

2

3

1

Feed paper/card

straight into paper

entry and release

When finished shredding

set to OFF ( )

Set to Auto-On (I)

Overheat Indicator: When the Overheat Indicator is illuminated, the shredder has exceeded its maximum operating temperature and needs to cool down. This indicator

will remain illuminated and the shredder will not operate for the duration of the recovery time. See Basic Shredding Operation for more information about the continuous

operation and recovery time for this shredder.

SafeSense

®

Indicator: If hands are too close to the paper entry, the SafeSense

®

indicator will illuminate and the shredder will stop shredding.

Alternate slowly back and forth

Set to Reverse (R)

for 2-3 seconds

Set to Off (O)

and unplug

Set to Auto-On (I) and

resume shredding

6

For more information about all of Fellowes Advanced Product Features go to

www.fellowes.com