37

threading or non-threading operations.

Feed Direction Lever: Selects carriage travel

direction.

The carriage moves left when feed direction

lever is up, half nut lever is engaged, and spindle

direction switch is set to “F”.

Carriage travel direction reverse when the

spindle switch is set to “R”.

Fig. 22 - 23

The carriage moves right when the feed direction

lever is all the way down.

The carriage will not move when the lever is in

center position.

End Gears Fig. 24

The end gears must be correctly setup for power

feed and threading.

Use the photo below to identify the A, B, C, and

D change gears, which are also referenced on

the headstock feed rate gear chart.

The following subsections explain how to

confi gure the end gears, which are accessed

by removing the end cover.

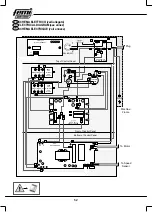

Power Feed Confi guration Fig. 25

The end gears are preset by the factory in this

confi guration, which is only used for power

feeding. Mesh the top 20T A gear with the 80T

B gear, and mesh the 20T C gear with the 80T

D gear.

Threading Confi guration Fig. 26

This threading configuration is used for a

diff erent range of threads and feed rates. Mesh

the A and B gears, and mesh the C and D gears,

The B and C gears share a keyed bushing.

End Gear Confi guration Example

Follow the example below to better understand

how to confi gure the end gears for threading.

To confi gure end gears for threading 2mm:

1. Disconnect Machine from power!

2. Located 2mm thread on gear chart

show.

Fig. 27

3. Remove end cover.

4. Loosen hex nut behind B/C change

gear shaft then slide B/C gear away

from D gear.

Fig. 28

5. Loosen adjusted hex nut down and

disengage gears.

Fig. 29

6. Remove cap screws and washers that

secure gears, then remove gears.

Note: If any gears are diffi

cult

to remove, use a large fl at head

screwdriver to gently wiggle them off .

7. Mount A-60T, B-50T, C-50T, D-45T gears

onto gear shafts according to threading

chart.

8. Then tighten adjuster hex nut and B/C

gear shaft hex nut.

9. Re-install end cover.

Backlash Adjustment

Backlash is the amount of free play felt while

changing rotation directions with the handwheel.

This can be adjusted on the cross slide

leadscrew. Before beginning any adjustment,

make sure all associated components are

cleaned and lubricated and locks are loose.

The cross slide backlash is adjusted by

tightening and loosening the inner and outer

cap screws. The inner screw adjusts the height

of the leadscrew nut, taking up lash between the

nut and leadscrew.

Angle the top slide so you can access the cap

screws. Loosen the outer cap screws, adjust

the inner cap screw, then tighten the outer cap

screws. cross slide handwheel back and forth

and adjust backlash.

Re-adjust the top slide angle when you fi nish it.

After a long period of time, you may fi nd that

the leadscrew develops excessive end-play

or lateral movement this lathe is designed so

that end play can be removed with a simple

adjustment.

Summary of Contents for JOB LINE DIGITO ML 350

Page 5: ...5...

Page 22: ...22 325 mm 760 mm 315 mm 2 1 20 Kg 3...

Page 51: ...51...

Page 55: ...55...

Page 58: ...58 Ingombro per etichetta FAC SIMILE Ingombro per etichetta FAC SIMILE...