14

EN

Defective motor, power cable or

plug.

Blown electric panel fuses.

No voltage in the mains system.

The overload cutout has tripped.

Motor overheating.

Motor overload caused by

excessive cutting pressure.

Motor breakdown.

The setting of the H and K retainers

(point 3.3) is inaccurate.

Excessive cutting pressure (on

pipes and section bars).

Incorrect blade toothing in relation

to the piece to cut.

Incorrect adjustment of the

eccentric and sliding blade-guides.

Incorrect cutting speed in relation

to the piece to cut.

The piece is wrongly positioned in

the vice.

The blade is worn or its toothing is

not right for the thickness of the

piece being cut.

Excessive cutting pressure.

Incorrect eccentric blade-guide

adjustment.

Excessive wear of the pulley

rubber linings.

The blade slips on the pulleys,

caused by oil or grease required

for cutting operations.

The motor does not

work.

Overload cutout tripped.

Inaccurate cutting angle

at 90° - 45°.

Inaccurate cut squaring.

Cut finish is coarse or

corrugated.

The blade tends to

protrude from the

guides.

Specialized personnel should check the machine; do

not attempt to repair the motor by yourself.

Check fuse integrity and replace, if necessary.

Check for voltage in the mains system.

Release the run button and wait a few minutes for

the overload cutout to reset.

Check that motor air intakes are clear.

Perform the cut on the piece at the correct pressure.

Specialized personnel should check the machine; do

not attempt to repair the machine by yourself.

Set the retainers by unloosening the fastening screws

and re-positioning them.

Decrease cutting pressure.

Check the cutting parameters (blade toothing, cutting

speed) in the cuts table (point 4.7).

Check blade-guide adjustment (points 3.5 and 3.6).

Check piece positioning and clamping in the vice

(point 4.5).

Check the cutting parameters (blade toothing, cutting

speed) in the cuts table (point 4.7).

Decrease cutting pressure.

Check eccentric blade-guide adjustment (point 3.6).

Specialized personnel should check the pulleys and

replace them if necessary.

Never use any type of lubricant or coolant for the

cutting operations; specialized personnel should

check and, if necessary, replace the pulleys.

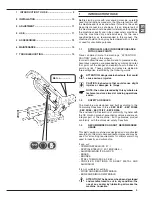

PROBLEMS

PROBLEMS CAUSES

SOLUTIONS SUGGESTED

7

TROUBLESHOOTING