www.fennerdrives.com

For technical assistance,

please call +1-717-665-2421

B-LOC

®

Shrink Discs provide a high capacity, zero-backlash shaft/hub or coupling

connection by means of a mechanical interference fit. Please follow these

INSTALLATION AND REMOVAL INSTRUCTIONS carefully to ensure proper

performance of this

B-LOC

®

unit.

WARNING

When installing or removing

B-LOC

®

products, always adhere to the following

safety standards:

1. Be sure that the system is de-energized using proper lockout/tagout

procedures.

2. Wear proper personal protective equipment.

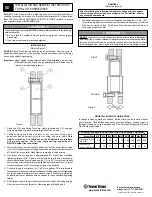

Figure 1

BEFORE

AFTER

INSTALLATION

(Refer to Figure 1)

B-LOC

®

SD40 Shrink Discs are supplied ready for installation. Therefore do not

disassemble the unit.

Important: Never tighten locking screws before shaft installation, as inner

ring of Shrink Disc and/or hub can be permanently contracted

even at relatively low tightening torques.

1. Clean hub O.D. and Shrink Disc bore. Lightly lubricate hub O.D. using ordinary

machine oil before assembling Shrink Disc on hub.

2. Carefully clean shaft and hub bore of any lubricant using a non-petroleum-

based solvent prior to mounting hub onto shaft.

This step is critical, as any

lubricant on the shaft/hub bore interface will greatly reduce the torque

transmitting capacity of a B-LOC

®

SD40 Shrink Disc connection.

3. After confirming correct position of hub and Shrink Disc, hand-tighten three

(3) or four (4) equally spaced locking screws making sure that inner and

outer ring are parallel. Hand-tighten remaining locking screws.

INSTALLATION WITH A TORQUE WRENCH

4. Use torque wrench and set it approximately 5% higher than specified

tightening torque (Ma). Tighten locking screws in either a clockwise or

counterclockwise sequence, using approx. 1/4 (i.e., 90°) turns (even if initially

some locking screws require a very low tightening torque to achieve 1/4 turns)

for several passes until 1/4 turns can no longer be achieved.

5. Continue to apply overtorque for 1 to 2 more passes. This is required to

compensate for a system-related relaxation of locking screws since tightening

of a given screw will always relax adjacent screws. Without over torquing,

an infinite number of passes would be needed to reach specified tightening

torque.

6. Reset torque wrench to specified torque (Ma) and check all locking screws.

No screw should turn at this point, otherwise repeat Steps 5 and 6.

INSTALLATION WITHOUT A TORQUE WRENCH

7. Tighten locking screws in either a clockwise or counterclockwise sequence,

using approx. 1/4 (i.e., 90°) turns for several passes until the faces of the

outer ring and inner ring are aligned flush. (See Figure 1 - After)

REMOVAL

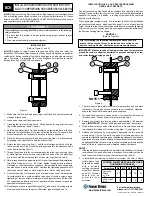

(Refer to Figure 2)

Prior to initiating the following removal procedure, check to

ensure that no torque or thrust loads are acting on the Shrink

Disc, shaft or any mounted components.

1. Loosen all locking screws in several stages by using approx. 1/2

(i.e., 180°) turns, following either a clockwise or counterclockwise

sequence, until Shrink Disc can be moved on hub. If the shrink disc

does not release, transfer the appropriate number of screws into

the threaded backoff holes in the outer ring (Figure 2). Evenly and

progressively tighten these screws, in either a clockwise or counter

clockwise sequence, until outer ring releases. The shrink disc, hub

and shaft will return to their original clearance fits.

Important: Prior to removal the ends of push off screws are to be

ground flat and chamfered to prevent damage to screw

and outer ring threads during backoff.

WARNING

DO NOT

completely remove all locking screws before outer ring is

disengaged from inner ring. A sudden release of the outer ring involves

high separating forces and could result in permanent injury or death. Be

certain that outer ring is disengaged from inner ring before completely

removing locking screws.

REINSTALLATION OF SHRINK DISCS

In relatively clean operating conditions, Shrink Discs can be re-used

without prior cleaning. Shrink Discs used under severe conditions, how-

ever, require thorough cleaning and re-lubrication with Dow Corning

®

Molykote

®

G-Rapid Plus Paste or equivalent.

LOCKING SCREW SIZES AND SPECIFIED TIGHTENING TORQUE M

a

Screw Size M8 M10 M12 M14 M16 M20 M24 M27 M30

Tightening

Torque

Ma (ft lb)

25

52

89 140 214 420 730 1092 1460

Wrench Size

Across Flats

(mm)

13

17

19

21

24

30

36

41

46

©2012 Fenner Drives B-PR-025 09/01/2012

Figure 2

INSTALLATION AND REMOVAL INSTRUCTIONS

FOR

B-LOC

®

SHRINK DISCS SERIES SD40

SD40

Grease-free