www.fennerdrives.com

For technical assistance,

please call +1-717-665-2421

B-LOC

® Keyless Bushings provide a high capacity, zero-backlash

shaft/hub or coupling connection by means of a mechanical interference

fit. Please follow these INSTALLATION AND REMOVAL INSTRUCTIONS

carefully to ensure proper performance of this

B-LOC

® unit.

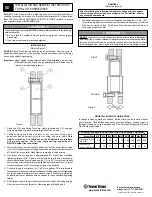

INSTALLATION

(Refer to Figure 1)

B-LOC

® Keyless Bushings are supplied lightly oiled and ready for installation.

The frictional torque capacity of these devices is based on a coefficient of friction

of 0.12 for lightly oiled screw, taper, shaft and bore contact areas.

Therefore, it is important not to use Molybdenum Disulfide (e.g., Molykote,

Never-Seeze or similar lubricants) in any Keyless Bushing installation.

1. Make sure that locking screw, taper, shaft and bore contact areas are clean

and lightly oiled with a light machine oil.

2. Insert Keyless Bushing into hub counterbore prior to shaft installation.

3. After confirming correct hub position, hand-tighten three (3) or four (4)

equally spaced locking screws until initial contact with shaft and hub bore is

established.

4. Use torque wrench and set it approximately 5% higher than specified

tightening torque (Ma). Tighten locking screws in either a clockwise or

counterclockwise sequence (it is not necessary to tighten in a diametrically

opposite pattern), using only 1/4 (i.e., 90°) turns for several passes until 1/4

turns can no longer be achieved.

5. Continue to apply overtorque for 1 to 2 more passes. This is required to

compensate for a system-related relaxation of locking screws since tightening

of a given screw will always relax adjacent screws. Without overtorquing,

an infinite number of passes would be needed to reach specified tightening

torque.

6. Reset torque wrench to specified torque (Ma) and check all locking screws.

No screw should turn at this point, otherwise repeat Steps 5 and 6.

NOTE

: 1. It is not necessary to re-check tightening torque after equipment

has been in operation.

2. In applications subject to extreme corrosion, the slits in all collars

can be sealed with a suitable caulking compound or equivalent.

INSTALLATION OF B-LOC® KEYLESS BUSHING

OVER SHAFT KEYWAYS

The Keyless Bushing should be positioned so that slits in Keyless Bushing

collars that contact the shaft are located approximately opposite the

keyway. In addition, a locking screw should be centered directly over the

keyway.

When tightening locking screws, it is important to follow the installation

procedure outlined above, which specifies equal 1/4 turns of each locking

screw. Failure to follow these instructions could result in excessive

tightening of the screw over the keyway, possibly causing permanent

deformation of the Keyless Bushing collars.

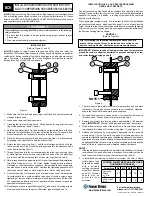

REMOVAL

(Refer to Figure 2)

Figure 1

dB = pull-off thread, located only under cadmium plated screws of front thrust collar

Cadmium plated screws

Prior to initiating the following removal procedure, check to

ensure that no torque or thrust loads are acting on the Keyless

Bushing, shaft or any mounted components.

1. Loosen locking screws in several stages by

using approx. 1/4 turns,

following either a clockwise or counterclockwise sequence.

NOTE:

B-LOC®

Series B400 Keyless Bushings feature self-releasing

tapers, meaning collars should release during Step 1. However,

if for some reason the thrust collars jam, a light tap on three (3)

equally spaced heads of loosened locking screws will positively

release the connection.

2. Hub and Keyless Bushing are normally removed together. Removal

of Keyless Bushing only from deep counterbores is accomplished by

inserting pull-off screws (not provided) into threads located under plated

locking screws. These threads are NOT to be used for high pulling

forces, as thrust collar is only partially threaded.

©2012 Fenner Drives B-PR-016 9/17/2012

INSTALLATION AND REMOVAL INSTRUCTIONS

FOR B-LOC

®

KEYLESS BUSHING SERIES B400

B400

Figure 2

LOCKING SCREW SIZES AND

SPECIFIED TIGHTENING TORQUE M

a

B400 KEYLESS BUSHINGS

Metric Series

Inch Series

Tightening

Torque

Ma

(ft lb)

Screw

Size

Hex

Key

Size

(mm)

Pull-off

Thread

dB

20 x 47

to 40 x 65

3/4

to 1-1/2

11

M6

5

M8

42 x 75

to 65 x 95

1-5/8

to 2-9/16

26

M8

6

M10

70 x 110 to 95 x 135

2-5/8

to 3-3/4

51

M10

8

M12

100 x 145 to 160 x 210

3-7/8

to 6

91

M12

10

M14

170 x 225 to 200 x 260

6-7/16 to 8

138

M14

12

M16

220 x 285 to 260 x 325

214

M16

14

M20

280 x 355 to 300 x 375

293

M18

14

M22

320 x 405 to 340 x 425

420

M20

17

M24

360 x 455 to 420 x 515

565

M22

17

M27

440 x 545 to 1000 x 1110

725

M24

19

M30

WARNING

When installing or removing

B-LOC

®

products, always adhere to the following

safety standards:

1. Be sure that the system is de-energized using proper lockout/tagout

procedures.

2. Wear proper personal protective equipment.