www.fptgroup.com

Fenner is a registered Trade Mark of Fenner PLC

All Dimensions are in Millimetres unless otherwise stated

Head Office: Amber Way, Halesowen, West Midlands. B62 8WG

w w w . f p t g r o u p . c o m

SERIES K

GEARMOTORS

Installation and Maintenance

4

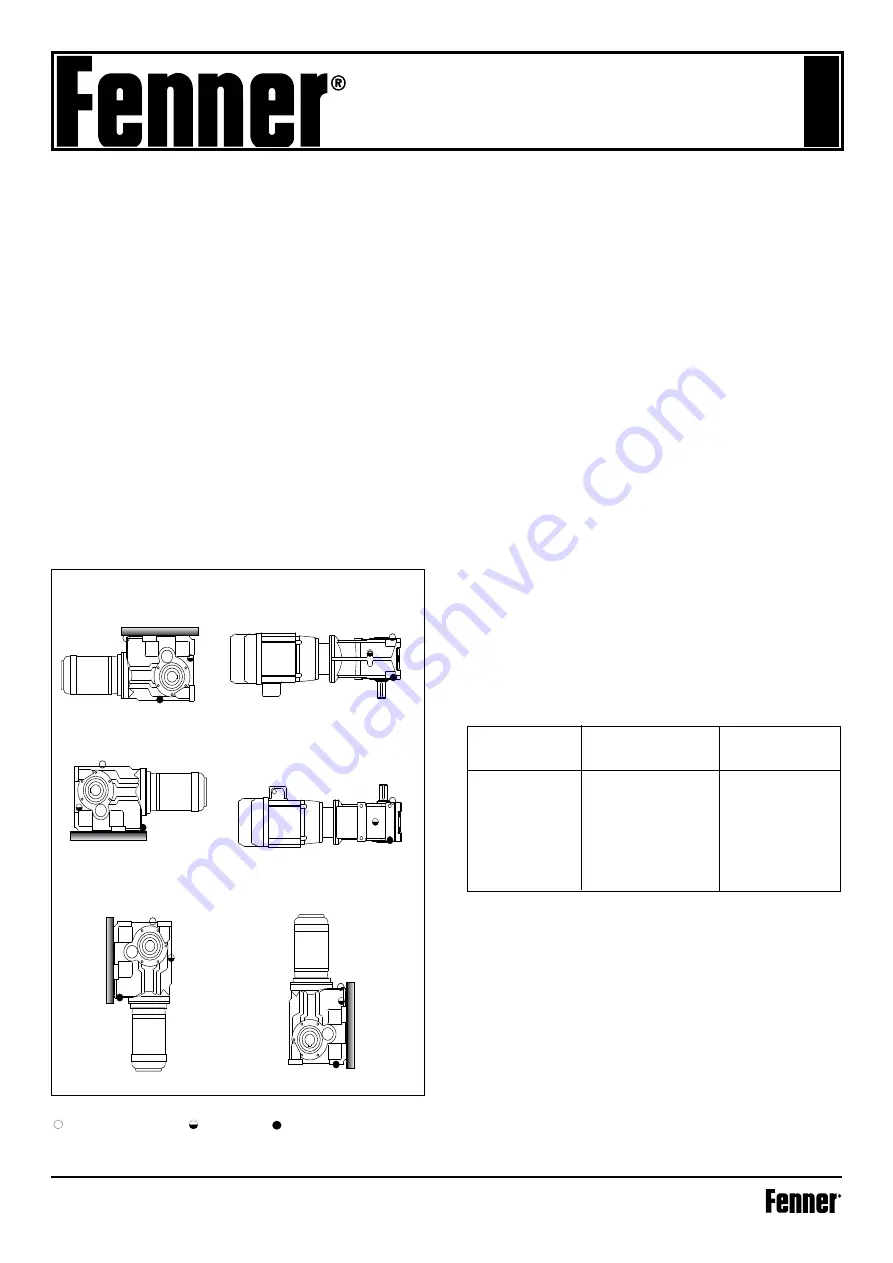

MOUNTING POSITIONS

Plug positions apply for sizes 893 and larger.

Ventilator/Filling Position Level Position Drain Position

SHAFT MOUNTING

Ensure that the shaft on to which the gear unit is to be mounted

and the gear unit bore are clean and free from burrs.

Liberally smear the shaft and bore with lubricants to aid

assembly and prevent fretting corrosion. Slide the unit on to the

driven shaft. Fit side fitting key.

DO NOT USE TAPER OR TOP

FITTING KEY

.

FOOT OR FLANGE MOUNTING

The Fenner series K is designed primarily as a shaft mounted

gearbox, however if a customer wishes to use the unit in the foot

mounted position all sizes have pre-cast feet built in to the gearcase

for mounting in the B3 position. Series K can also be used as a

flange mounted unit, standard output flanges area available as acces-

sories. Consult you local Authorised Distributor for details. Use the

tightening torques listed below for holding down bolts.

Clean shaft extensions and ventilator where fitted

The shafts of the unit and driven equipment should be in as perfect

alignment as possible. Fenaflex

®

couplings should be used when

shaft alignment cannot be assured and also when protection from

peak and vibrating torques are desirable. Ensure the base foundation/

flange mounting surface is flat*, vibration and torsionally rigid.

The drive should be mounted on a rigid support and bolted down

firmly using set screws to ISO grade 8.8 minimum. Ensure that ma-

chined mounting points are supported over their full area. If packing

is to be used, place either side of the mounting bolt. During the final

bolting down ensure the unit and/or baseplate are not distorted to

maximise unit performance.

For units mounted on bedplates, dowel two diagonally opposite feet

in to position.

Fit all guards required to comply with the factory acts, check the mo-

tor wiring for correct direction of rotation and check oil levels.

*Maximum permissible flatness error for mounting surface is 0.12mm.

MOTOR CONNECTIONS TO MAINS

Connection of the electric motor to the mains supply should be

made by a qualified person.The current rating of the motor will be

identified on the motor plate and correct sizing of the cables to

electrical regulations is essential.

STARTING UP

Prior to starting up the following procedure should be followed

1. Ensure Ventilator is fitted ( size 893 and above

2. Check Oil level (893 and above) top up if necessary

3. Ensure all safety devices are in place (i.e. guards fitted)

4. Remove any safety devices fitted to prevent machine rotation

Starting up should be performed or supervised by suitably quali-

fied personnel.

BREATHERS/MOUNTING POSITIONS

Sizes 890,891 & 892 are supplied for operation without breathers.

Size 893 is supplied for operation with a breather but to prevent

leakage during transit this unit is fitted with blanking plugs. It

is essential that when the unit is in its operating position the

relevant blanking plug is removed and replaced by the breather

plug (supplied) in the position indicated on the installation leaflet.

Sizes 894 to 898 are supplied for operation with a breather but are

despatched without oil.

It is essential that when the unit is in its operating position the

relevant blanking plug is removed and replaced by the breather

plug (supplied) in the position indicated on the installation leaflet.

1. Ensure Ventilator is fitted (size 893 and above)

2. Check Oil level (893 and above) top up if necessary

3. Ensure all safety devices are in place (i.e. guards fitted)

4. Remove any safety devices fitted to prevent machine rotation

Starting up should be performed or supervised by suitably quali-

fied personnel.

Ceiling Mounted (B8)

Left Hand Wall Mounting (B6)

Vertical Mounting Shaft Up (V6) Flange Mounting Shaft Up (V3)

Vertical Mounting Shaft Down (V5) Shaft Down Flange Mounting (V1)

Right Hand Wall Mounting (B7)

Standard Floor Mounted (B3)

Set Screw

Foot & Output

Motors to

Size

Flange Bolts

Gearhead

Torque (Nm)

M6

10

10

M8

25

18

M10

50

37

M12

85

64

M16

200

150

M20

350

260

M24

610

-

M30

1220

-

M36

2150

-

Summary of Contents for K Series

Page 10: ......