Effective: October 2018

06-237172-002

5

TROUBLESHOOTING

Before troubleshooting the system, check the following items:

•

Verify all mechanical and electrical connections are secure

and tight.

•

Verify all system wiring is correct.

•

Verify there is a proper system ground. The igniter, flame

sensor, and ignition module must share a common ground

with the burner.

Nuisance shutdowns are often caused by a

poor or erratic ground.

•

Perform the instructions in “Checkout” on page 4, as the

first step in any troubleshooting.

•

Verify that the system is powered and that the thermostat is

calling for heat.

•

Verify the green power LED is lit, indicating 24 VAC power

to the control.

•

If the control proceeds to an error code on the red

diagnostic LED, troubleshoot per the Fault Conditions table

below:

The LED will flash on for 1/4 second, then off for 1/4 second

during a fault condition. The pause between fault codes is 3

seconds.

FLAME CURRENT MEASUREMENT

Flame current is the current that passes through the flame from

sensor to ground. To measure flame current, connect a True

RMS or analog DC micro-ammeter to the FC+ and the FC-

terminals. The reading should be 1.0 micro-amps DC or higher.

If the meter reads negative or below “0” on the scale, the meter

leads are reversed. Re-connect leads with proper polarity.

Alternately, a Digital Voltmeter may be used to measure the DC

voltage between the FC+ and FC- terminals. Each micro-amp

of flame current produces 1.0 VDC, so a reading of 2.6 VDC

would equate to 2.6 micro-amps.

A good burner ground that matches the control ground is critical

for reliable flame sensing.

INTERNAL CONTROL FAILURE

If the control detects an error in its software or hardware, all out-

puts are turned off and the red LED displays a steady ON condi-

tion. If this condition persists after an attempt to restart then the

control must be replaced.

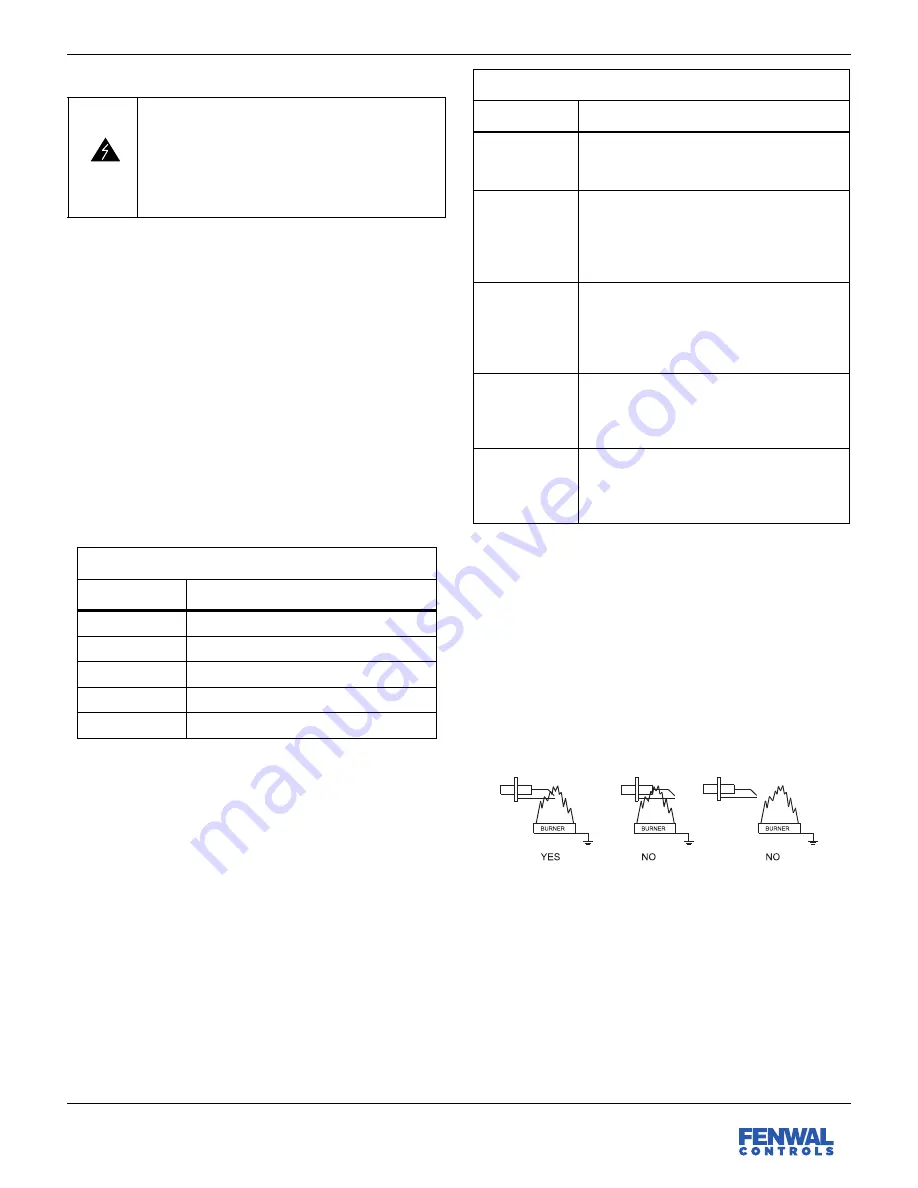

PROPER ELECTRODE LOCATION

Proper location of the electrode assembly is important for

optimal system performance. The electrode assembly should

be located so that the tips are inside the flame envelope and

about 1/2 inch (1.2 cm) above the base of the flame.

•

Ceramic insulators should not be in or close to the flame.

•

Electrode assemblies should not be adjusted or disassem-

bled. Electrodes should have a gap spacing of 0.125±

0.031 inch (3.12± 0.81 mm), unless otherwise specified by

the appliance manufacturer. If this spacing is not correct,

the assembly must be replaced. Electrodes are NOT field-

adjustable.

•

Exceeding the temperature limits can cause nuisance lock-

outs and premature electrode failure.

•

Electrodes must be placed where they are not exposed to

the appliance user in normal operation.

WARNING

Risk of Explosion or Fire

The 35-608 control cannot be serviced by the user.

If any control faults are detected, the 35-608 con-

trol must be replaced by qualified service person-

nel. Risk of explosion or fire can result if the control

module has been opened or with any attempts to

repair it, and the warranty is void.

Fault Conditions

LED Indication

Fault Mode

Off

Normal Operation

2 Flashes

Flame without call for heat

3 Flashes

Ignition Lockout

4 Flashes

Manual Reset Error

Steady On

Internal Control Failure

Troubleshooting Guide

Symptom

Probable Cause

1. Control does

not start, green

LED is off.

A. Mis-wired

B. 24 VAC Transformer bad

C. Fuse/Circuit breaker bad (no power)

2. Thermostat

on - no spark or

valve

A. Mis-wired

B. Bad thermostat, no voltage at thermostat

terminal TH

C. Bad control, check red LED for steady

on or flashing codes.

3. Valve on - no

spark during

TFI

A. Shorted electrode

B. Spark gap not correct. Set to .094-.156

inch.

C. High voltage cable is faulty or has a poor

connection.

4. Spark on -

valve off

A. Gas Valve coil open

B. Valve wire disconnected

C. Bad control, check voltage between gas

valve terminal MV and GND.

5. Flame okay

during TFI - no

flame sense

after TFI

A. Check electrode position and cleanliness

B. Check high voltage wire

C. Poor ground at burner

D. Poor flame, check flame current