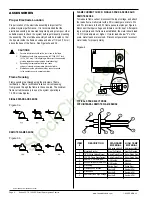

1/4”

3/16”

3/16”

3/16”

1/4”

3/16”

1/4”

Alarm

Valve Power

120 VAC (Neutral)

Valve Neutral

120 VAC Input (Hot)

Burner Ground

Remote Flame Sensor

Flame Sense Test Pins

NC

V1

L2

V2

L1

B. GND

S1

*

FC+, FC-

11

10

8

7

6

2

1

Lt. Blue

Brown

White

Yellow

Black

Purple

Gray

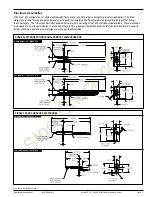

MOUNTING AND WIRING

The 35-70 is not position sensitive and can be mounted vertically or

horizontally. The control may be mounted on any surface and fastened

with #6 sheet metal screws. Secure the control in an area that will

experience a minimum of vibration and remain below the maximum

ambient temperature of 80°C (175°F).

All connections should be made with UL approved, 105°C rated, 18

gauge, stranded, .054” thick insulated wire. Refer to the appropriate

wiring diagram when connecting the 35-70 to other components in the

system. High voltage spark cables and control wiring harnesses are

detailed on Pages 5 and 6.

SYMPTOM

Control will not start up

Gas Valve on and no spark

through TFI

Spark on and gas valve off

Flame during trial

for ignition but

no flame sense after

trial for ignition

I

nput Power

Input Current Drain

Gas Valve Rating

Operating Temperature

Flame Sense Voltage

Flame Sense Current

Flame Failure Response Time

Types of Gas

Spark Rate

Moisture Resistance

Size (LxWxH)

Weight

102 to 138 VAC, 50/60 Hz

350mA @ 120 VAC, 60 Hz

1.5A @ 120 VAC

-40°F to +175°F, -40°C to +80°C

120 VAC

1.0 microamp minimum

0.8 seconds maximum

Natural, LP and manufactured

Line frequency (50/60 Hz)

Conformal coated to operate to 95% R.H.

See drawings on Page 8

Integral stand-offs: 7.1 oz Potted:14.3 oz

Case and Cover: 10.1oz

RECOMMENDED ACTIONS

A. Check wiring

B. No voltage @ L1, check thermostat

C. Check fuse/circuit breaker

D. Faulty transformer on control

E. Faulty control, consult Fenwal

A. Shorted electrode - re-establish 1/8” gap

B. High voltage cable is disconnected

C. Check wiring

A. Valve coil open

B. Valve wire disconnected

C. Faulty control, check voltage @ V1

A. Check electrode position

B. Check high voltage wire and connection

C. Poor ground @ burner

D. Check flame current

E. Check flame current on control

SINGLE SPARK AND SENSE

REMOTE SENSE

TERMINAL

DESCRIPTION

MULTI-PIN

CONNECTOR

P/N: AMP 1-644615-1

QUICK

CONNECT

TERMINAL

SIZE

SPECIFICATIONS

TROUBLESHOOTING GUIDE

Terminal Designations

WARNING:

Operation outside specifications could result in failure of

the Fenwal product and other equipment with injury or death to people

and damage to property

.

PIN

LOCATION

WIRE

COLOR

CAUTION:

Label all wires prior to disconnection when servicing the control.

Wiring errors can cause improper and dangerous operation. A functional

checkout of a replacement is recommended.

LED Indication

Steady on

2 Flashes

3 Flashes

Fault Mode

Internal Control Failure

Flame Fault

**

Ignition Lockout Fault

The LED will flash on for 0.2 seconds then off for 0.2 seconds to indicate

an error condition. The pause time between error codes will be 2.5 to 3.0

seconds. During power-up, the LED will light for one second and then turn

off to indicate normal operation.

ON-BOARD DIAGNOSTICS

2 Pin Header

(AMP P/N: 640383-2, Molex P/N: 26-60-2020)

PIN LAYOUT

*

On controls configured for single spark and sense with quick connects, the

S1 terminal is removed. On controls configured for single spark and sense with

multi-pin connector, leave S1 wire, pin 1, color gray unconnected.

Series 35-70, 120 VAC Direct Spark Ignition Control

Page 3

www.fenwalcontrols.com

1-800-FENWAL-1

**

May indicate either that a flame was detected during pre- or post-purge,

or that there is a flame sensing error.

StockCheck.com

Downloaded from StockCheck.com