FERtech F 24 D - F 32 D

15

EN

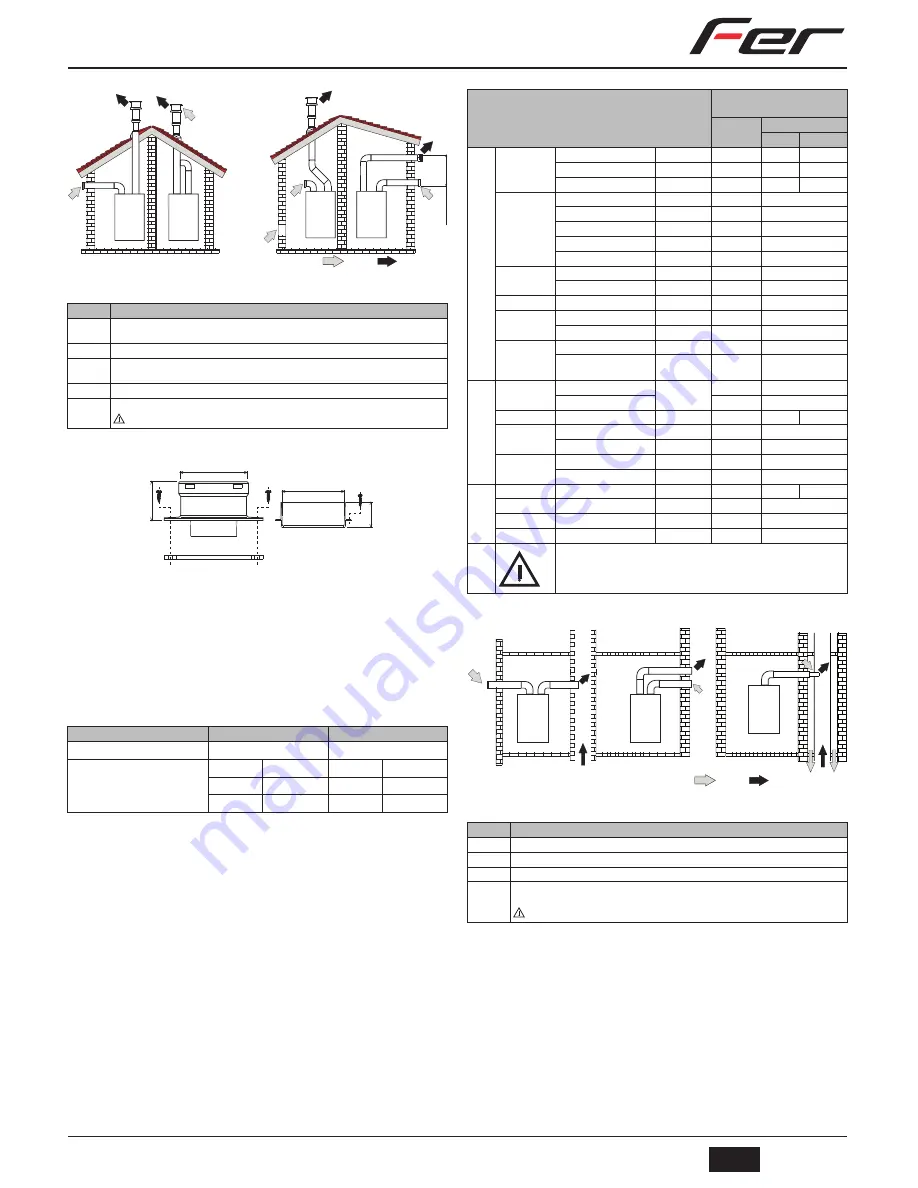

Connection with separate pipes

fig. 11 - Examples of connection with separate pipes (

= Air /

= Fumes)

Table. 4 - Typology

For the connection of separate ducts, fit the unit with the following starting accessory:

fig. 12 - Starting accessory for separate ducts

Before installation, check the baffle to be used and that the maximum permissible length

is not exceeded, by means of a simple calculation:

1.

Completely establish the layout of the system of split flues, including accessories

and outlet terminals.

2.

Consult the table 6 and identify the losses in m

eq

(equivalent metres) of every com-

ponent, according to the installation position.

3.

Check that the sum total of losses is less than or equal to the maximum permissible

length in table 5.

Table. 5 - Baffles for separate ducts

Table. 6 - Accessories

Connection to collective flues

fig. 13 - Examples of connection to flues (

= Air /

= Fumes)

Table. 7 - Typology

If the boiler is to be connected

FERtech F 24 D - F 32 D

to a collective flue or a single

flue with natural draught, the flue or chimney must be expressly designed by profession-

ally qualified technical personnel in conformity with the current regulations and be suita-

ble for sealed chamber units equipped with fan.

Type

Description

C1X

Wall horizontal exhaust and intake. The inlet/outlet terminals must be concentric or close enough to be

undergo similar wind conditions (within 50 cm)

C3X

Roof vertical exhaust and intake. Inlet/outlet terminals like for C12

C5X

Wall or roof exhaust and intake separate or in any case in areas with different pressures. The exhaust

and intake must not be positioned on opposite walls.

C6X

Intake and exhaust with separately certified pipes (EN 1856/1)

B2X

Intake from installation room and wall or roof exhaust

IMPORTANT - THE ROOM MUST BE PROVIDED WITH APPROPRIATE VENTILATION

FERtech F 24 D

FERtech F 32 D

Max. permissible length

60 m

eq

48 m

eq

Baffle to use

0 - 20 m

eq

Ø 43

0 - 15 m

eq

Ø 45

20 - 45 m

eq

Ø 47

15 - 35 m

eq

Ø 50

45 - 60 m

eq

No baffle

35 - 48 m

eq

No baffle

C

5x

C

3x

B

2x

C

1x

max 50 cm

50

80

010011X0

80

32

Losses in m

eq

Air

inlet

Fume exhaust

Vertical

Horizontal

Ø 80

PIPE

0.5 m M/F

1KWMA38A

0.5

0.5

1.0

1 m M/F

1KWMA83A

1.0

1.0

2.0

2 m M/F

1KWMA06K

2.0

2.0

4.0

BEND

45° F/F

1KWMA01K

1.9

2.9

45° M/F

1KWMA65A

1.9

2.9

90° F/F

1KWMA02K

2.0

3.0

90° M/F

1KWMA82A

1.5

2.5

90° M/F + Test point

1KWMA70U

1.5

2.5

PIPE SECTION

with test point

1KWMA16U

0.2

0.2

for condensate drain

1KWMA55U

-

3.0

TEE

for condensate drain

1KWMA05K

-

7.0

TERMINAL

air, wall

1KWMA85A

2.0

-

fumes, wall with antiwind

1KWMA86A

-

5.0

FLUE

Split air/fumes 80/80

1KWMA84U

-

12.0

Fume outlet only Ø80

1K

1KWMA86U

-

4.0

Ø 100

REDUCTION

from Ø80 to Ø100

1KWMA03U

0.0

0.0

from Ø100 to Ø80

1.5

3.0

PIPE

1 m M/F

1KWMA08K

0.4

0.4

0.8

BEND

45° M/F

1KWMA03K

0.6

1.0

90° M/F

1KWMA04K

0.8

1.3

TERMINAL

air, wall

1KWMA14K

1.5

-

fumes, wall with antiwind

1KWMA29K

-

3.0

Ø 60

PIPE 1 m M/F

010028X0

-

2.0

6.0

BEND 90° M/F

010029X0

-

6.0

REDUCTION 80 - 60

010030X0

-

8.0

TERMINAL fumes, wall

1KWMA90A

-

7.0

ATTENTION: CONSIDER THE HIGH PRESSURE LOSSES OF Ø60 ACCESSORIES;

USE THEM ONLY IF NECESSARY AND AT THE LAST FUME EXHAUST SECTION.

Type

Description

C2X

Intake and exhaust in common flue (intake and exhaust in same flue)

C4X

Intake and exhaust in common and separate flues , but undergoing similar wind conditions

C8X

Exhaust in single or common flue and wall intake

B3X

Intake from installation room by means of concentric duct (that encloses the exhaust) and exhaust in

common flue with natural draught

IMPORTANT - THE ROOM MUST BE PROVIDED WITH APPROPRIATE VENTILATION

C

8X

C

2X

C

4X

cod. 354

%

581

- Rev. 0

3

-

/201

5

Summary of Contents for FERtech F 24 D

Page 31: ......