MIKRO P7 - P12

21

EN

cod. 3540T988 - Rev. 01 - 01/2014

3.3 Electrical connections

The burner is equipped with a multi-pole terminal block for the electrical connections; re-

fer to the wiring diagram in section “

4 Technical data and characteristics

" for the con-

nections. The connections to be made by the installer are:

•

Supply line

•

Request contact

•

Auger motor connection

•

Temperature probe connection

•

Boiler safety thermostat connection

The length of the connection cables must allow the burner and, if necessary, the boiler

door to be opened. If the burner power cable is damaged, it must only be replaced by

qualified personnel.

The burner must be connected to a single-phase 230 Volt-50 Hz electric line.

B

Have the efficiency and suitability of the earthing system checked by profes-

sionally qualified personnel; the Manufacturer declines any liability for damage

caused by failure to earth the system. Also make sure the electrical system is

adequate for the maximum power absorbed by the unit, as specified on the boil-

er data plate.

Make sure to respect the polarities (LINE: brown wire / NEUTRAL: blue wire /

EARTH: yellow-green wire) in the connections to the electric line.

3.4 Fuel supply

General Instructions

The burner must be fed with the type of fuel for which it is arranged, as specified on the

unit's dataplate and in the technical data table on sec. 5.3 of this manual.

The user is advised to use good quality pellets, since low quality pellets result in low heat

outputs, high ash content with subsequent need of frequent cleaning, possible early wear

of burner parts exposed to the fire, clogging of the auger and burner due to excess loose

sawdust, and operation shutdowns due to sedimentation of unburnt materials inside the

burner.

To identify quality pellets it is advisable to proceed as follows:

•

They must be cylinders of constant diameter and have a smooth and bright surface.

•

Check that the labels give the details of the quality certifications

•

Check that the packs are intact so that the pellets do not absorb humidity.

Load pellets

Pellet loading can be activated within 40 minutes after switching on the power to the

burner.

Within this time, the system makes available three 5-minute attempts, during which only

the auger is activated.

The burner cannot be lit during pellet loading.

Sequence:

1.

Switch on the power to the burner.

2.

Wait for the pre-ventilation stage to end.

3.

Remove the burner lighting request: open the request contact (Method A, default

setting) or set the manual OFF mode (Method B and C).

4.

Press and hold down the Override button “x->” (detail 3 - fig. 1) for 3 seconds.

- The message "PELt", identifying the imminent start of the PELLET loading proce-

dure, will be displayed.

- After two seconds, the auger will be electrically powered and continuously for a

maximum time of 5 minutes.

- PELLET loading can be terminated at any time by pressing and holding down the

Override button “x->” (detail 3 - fig. 1) for 3 seconds.

5.

If the maximum pellet loading time (5 minutes) is reached, the power to the auger is

switched off.

6.

Press and hold down the Override button “x->” (detail 3 - fig. 1) for 3 seconds.

- The message "PELt" will disappear and the display returns to normal operation.

7.

If the first attempt was not sufficient, repeat the previous sequence from point 4 to

start the second attempt

8.

If the second attempt was not sufficient, repeat the previous sequence from point 4

to start the third and last attempt

9.

In order to do another 3 attempts, switch the power to the unit off and then on again

10. After pellet loading, reinstate the burner lighting request: close the request contact

(Method A, default setting) or set the Automatic or manual ON mode (Method B and C)

4. SERVICE AND MAINTENANCE

All adjustment, commissioning and maintenance operations must be carried out by Qual-

ified Personnel in compliance with the current regulations. The personnel of our sales or-

ganisation and the Local After-Sales Technical Service are at your disposal for any

further information.

FER

declines any liability for damage and/or injury caused by unqualified and unauthor-

ised persons tampering with the unit.

4.1 Burner operation methodology

Three methods of burner ignition management are foreseen:

A - Burner management (default setting)

The request for burner lighting is activated only on closing of the contact on terminals 7-

8 (see fig. 14).

A

The clock and the set weekly programme are bypassed: the exact time does

not have to be set.

B - Burner management (with internal Clock or Contact)

The request for burner lighting can be activated by the Clock (during Automatic Heating

Mode in ON Band or in Manual On Heating Mode) or with closing of the contact on ter-

minals 7-8 (see fig. 14).

A

It is necessary to set the Clock and possibly modify the weekly programme de-

fault setting.

C - Burner management (with internal Clock and Contact)

The request for burner lighting is activated by the Clock (during Automatic Heating Mode

in ON Band or with Manual On Heating Mode) and if the contact on terminals 7-8 is

closed (see fig. 14).

A

It is necessary to set the Clock and possibly modify the weekly programme de-

fault setting.

The selection of A, B or C occurs from the Clock user menu.

Press the operation mode selection button "M" (detail 2 - fig. 1) for 5 seconds.

Press the Programming button "P" (detail 5 - fig. 1) twice.

Parameter no. 3, identified by the message SET 03, is displayed.

Set to 00 for mode A, 01 for mode B, or 02 for mode C with the + and - buttons (details

4 and 6 - fig. 1).

After selecting the method, it is necessary to wait 3 seconds: the data flashes and is

stored. Press the operation mode selection "M" button (detail 2 - fig. 1) for 5 seconds to

exit the menu.

4.2 Commissioning

Checks to be made at first lighting, and after all maintenance operations involving dis-

connection from the systems or any operation on safety devices or parts of the burner:

Before lighting the burner

•

Make sure the burner is correctly fixed in the boiler with the preliminary settings in-

dicated above.

•

Make sure the boiler and system are filled with water or diathermic oil, the water cir-

cuit valves are open and that the flue is free and correctly sized.

•

Check closing of the boiler door, so that the flame is only generated inside the com-

bustion chamber.

•

Check the correct positioning of the auger and the burner connection flexible tube.

•

Fill the hopper with pellets.

•

Check the correct positioning and connection of the temperature probe.

A

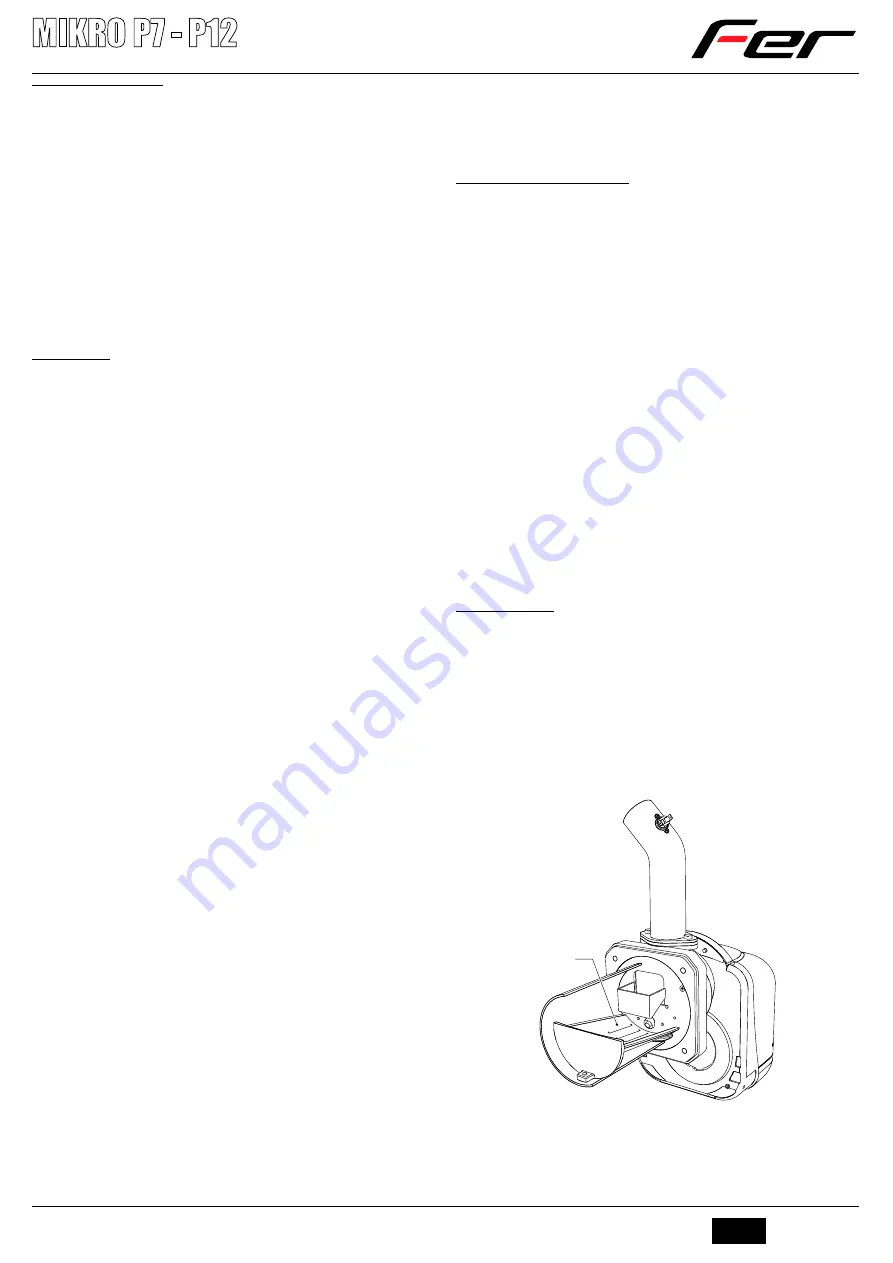

Make sure the grille (detail 1 fig. 9) is clean.

fig. 9 - Burner grille

1