50

VII. ADJUSTmENTS

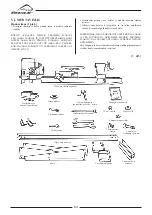

Headstock (Fig. 9)

1. The headstock has 5 preset positions,

• 0º setting for all spindle turning applications,

• 60º / 90º / 120º for use when making faceplate turning.

• 180º for use faceplate turnings when using the extension bed

and tool rest.

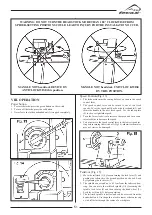

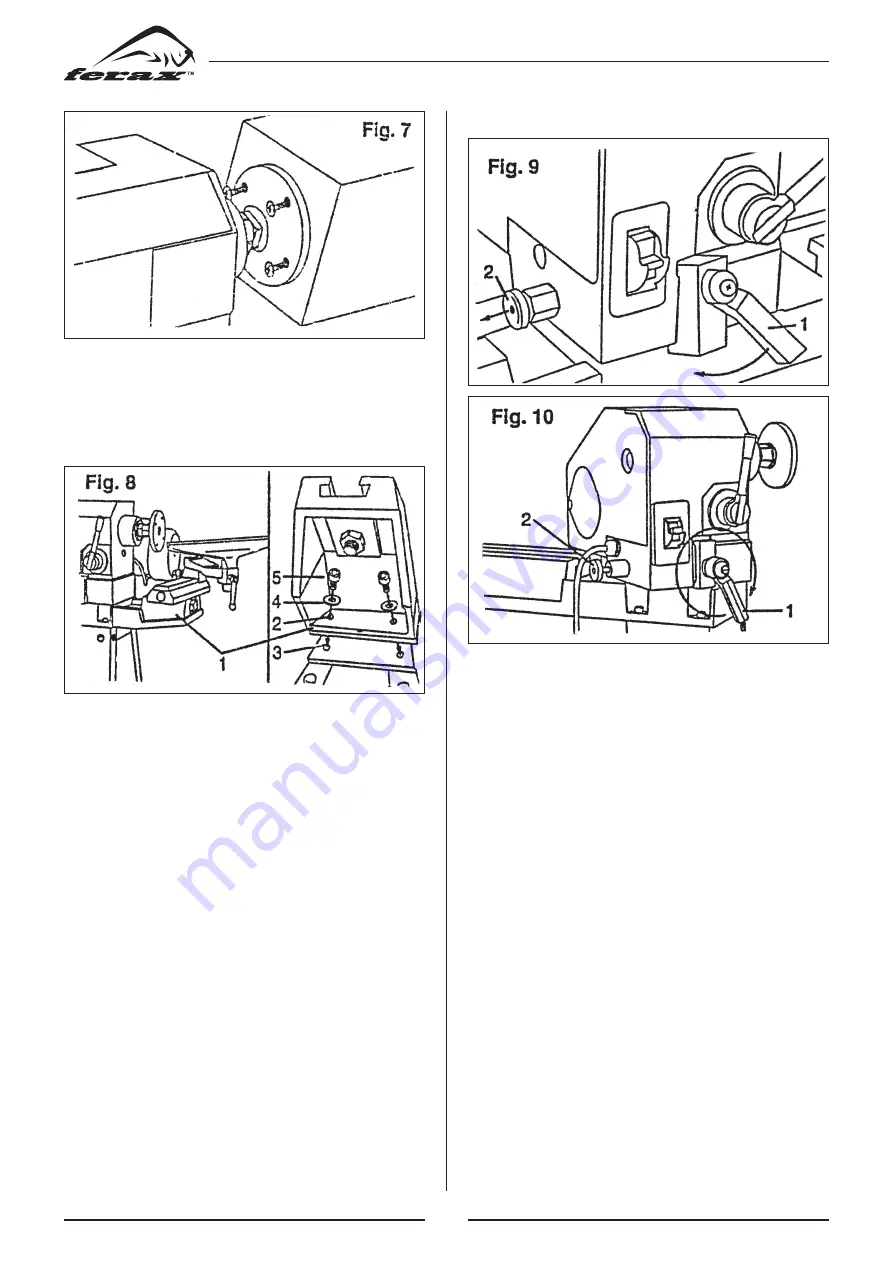

2. To set the headstock at the desired position, you must first turn

the head lock handle (1) until you have conpleted at least one

rotation. (Fig. 10)

3. Pull out the headstock release(2), rotate the entire headstock

clockwise to the desired position. The headstock will be fixed

in position when it clocks into one of the five pre-set setting.

Tighten the lock handle (1).

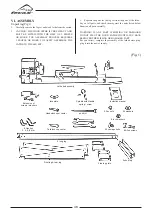

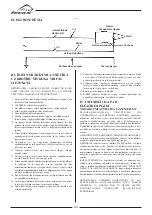

FACEPLATE (Fig. 7)

1. Remove the headstock spur from the spindle.

2. Thread the 6 inch diameter faceplate to the spindle.

3. Mount the workpiece to the faceplate with the flat head brass

wood screws.Make sure the length of the screws does not inter-

fere with the cutting tools.

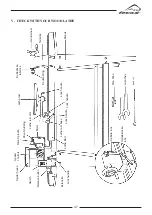

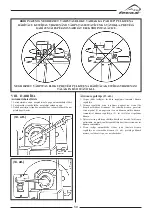

Förlängning (Fig. 8)

1. Extension bed is mounted firmly to the left of the house at

the turning spindle with external flat disc and using the fence

is necessary. (Except for BTS 1100 - here you can place the

headstock something inside so that the space provided for the

installation of lathing on the outer side.)

2. If the lathe with no exterior flat disc does not require use of the

fence, the bed extension is not installed until necessary.

3. To mount the extension bed to bed fit the bed with bolt holes

threaded holes. Put the lock washer on the 6-point bolt. Screw

in the first finger strength, then tighten the related 6-point key.

WARNING: DO NOT OPERATE YOUR WOOD LATHE until

it is completely assembled and adjusted according to the instruc-

tions.

Summary of Contents for 10320-0101

Page 2: ......

Page 4: ......

Page 79: ...79 FTS 900 ...

Page 80: ...80 FTS 1100 ...

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......