68

Fig. 7

Saw blade’s tension (Fig.8)

WARNING!

A too high tension can break the saw blade. If the ten-

sion is too low, the saw blade can slip from the driving

wheel and stop.

Saw blade’s tension must be adjusted according to the

different width of the saw blades in order to obtain a

correct alignment, efficiency and suitable life’s length.

• Lift the upper blade guide completely.

• To check blade’s tension, push sideways the saw

blade, in the middle between the workbench and the

upper blade guide: the saw blade must bend on its

side from 1 to a maximum of 2 mm.

• If necessary, adjust saw blade’s tension:

• Turn the handle 28 clockwise to increase the ten

-

sion;

• Turn the handle 28 anti-clockwise to reduce the

tension.

Fig. 8

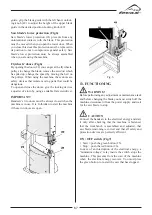

Knob for the adjustment of the blade’s position

(Fig.9)

To work correctly the saw blade must be centred on

flywheel rubber coatings. If it is not aligned you must

modify upper flywheel’s inclination. By using the

knob ( 29 ) you can modify the inclination of the fly-

wheel and thus:

• Turn the knob clockwise to move the blade back

-

wards.

• Turn the knob anti-clockwise to move the blade for

-

wards.

To lock upper flywheel’s inclination, tighten the

plastic wing screw located under the adjustment knob.

Fig. 9

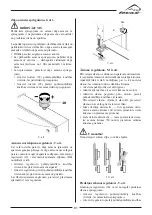

Speed adjustment (Fig. 5-10)

By moving the belt on the engine and flywheel pulleys

you can use the bandsaw at two different speeds.

Inside the lower door there are some instructions

explaining how to place the belt to obtain two different

speeds.

• Open the lower door with a screwdriver.

• Loosen the screws motor indicated

• Loosen the belt by turning the motor unclockwise.

Move the belt on the desired position, tighten

the belt again and close the lower door by using a

screwdriver.

• Small engine pulley – large flywheel pulley: blade

speed 360 m/min, suitable for hard wood types,

plastics.

• Large engine pulley – small flywheel pulley: blade

speed 720 m/min for all soft wood types.

CAUTION

Do not place the belt obliquely, since it would suffer

damages.