5.0 INSTALLATION OF THE

WELDING WIRE

The power source is supplied with a welding wire

spool. In order to install this wire into the feeding

system, follow the instructions hereafter described and

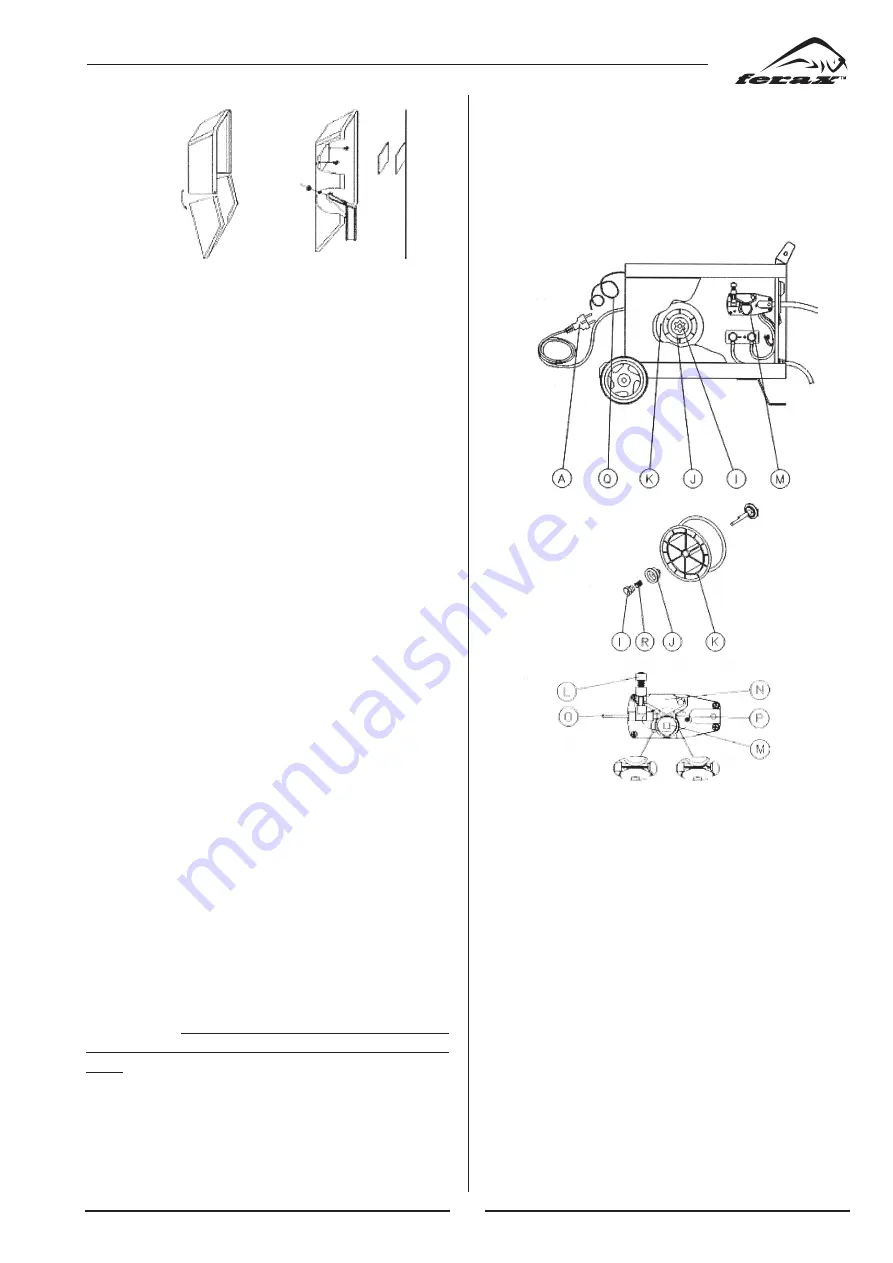

refer to Figure 3.

FIG. 3

33

FIG. 2

5. In order to assemble the handshield protection shield

in the special opening screws. Place the handle fix-

ing it in mask, push it and rotate it by 90° until insi-

de the protection mask.

CAUTION: Never look at an electric arc without

eye protection, the arc rays can injure the eyes per-

manently. Use always the protection shield supplied

with the power source or any other protection mask

or welding helmet.

4.0 WELDING SHIELD

MAINTENANCE

USE:

The shield are for personal use and must only be

used to protect the welder from the optical radiation

produced by the eletric welding arc.

CLEANING AND MAINTENANCE:

Clean the shi-

eld after each time it is used. The shield should only be

cleaned using a soft cloth or compressed air: check

whether any parts of the shield are worn and replace

these if damaged. The materials used to make the shi-

eld are usually compatible but can cause allergic reac-

tions in particularly sensitive people. Disinfecting

should be performed using solutions of benzil-lauryl-

dimethyl-ammonium chloride or UV germicide lamps.

LEVELS OF PROTECTION

: Only use the shield in

accordance with the operating instructions and make

sure that the protection filter is suited to the type of

welding. Remember that the filters are NOT shatter-

proof and therefore they should be protected by colour-

less plates of same size. To obtain a better level of the

protection against welding spatter , wear gloves and

protective clothing.

SPARE PARTS:

Replace any parts that seem damaged

or deformed immediately. Only original spare parts

must be used. Do not use filter glass as replacements if

these are not certified or do not have a declared optical

class. Ensure that any replacement filter is the correct

safety shade. If in doubt consult your local supplier.

RESTRICTIONS OF USE:

The shields only provide

adequate protection for the forehead, the sides of the

face and the neck if used for the stated purpose.

1. Loosen the nut (I) of the spool holder (brake drum)

and remove the spring (R) and the external ring.

2. Remove the plastic protection from the spool (K)

and place it on the spool holder again. Mount the

external ring (J), the spring (R) and the plastic lock

nut (I) again. These parts form the braking system of

the wire spool speed. NOTE: Do not tighten the nut

too much, excessive pressure strains the wire fee-

ding motor, while too little pressure does not allow

the immediate stop of the wire spool at the end of

the welding.

3. Loosen and lower the plastic knob (L), release the

upper roll of the feeder (N) and extract the wire from

the torch liner.

4. When the wire is disconnected, keep it with pliers so

that it cannot exit from the spool, and if necessary

straighten it before inserting it in the wire input

guide (O). Insert the wire on the lower roll (M) and

in the torch liner.