6

EN

• Do not remove any wood debris etc, in the

vicinity of the saw with your hands while it is

running. Turn the machine off before removing

the wood debris.

Immediately switch off the machine when

• Interruption in the mains plug, mains lead or

mains lead damage.

• Defect switch.

• Smoke or stench of scorched isolation.

Electrical safety

When using electric machines always observe the

safety regulations applicable in your country to

reduce the risk of fire, electric shock and personal

injury. Read the following safety instructions and

also the enclosed safety instructions.

Always check that the power supply

corresponds to the voltage on the rating

plate.

Mains connection

Only use earthed sockets with earthing wire

connected per the regulations.

Replacing the mains connection cable

The mains connection cable may only be replaced

by a special cable in a specialised workshop.

Replacing cables or plugs

Dispose of old cables or plugs immediately after

replacing them. It is dangerous to connect the plug

of a loose cable to a wall socket.

Using extension cables

Only use an approved extension cable,

corresponding to the machine power use. The wires

must have a minimum cross section of 1.5 mm

2

.

If the cable is on a reel, it must be fully paid out.

3. INSTALLING ACCESSORIES

Always disconnect the machine from the

main power supply before carrying out

any maintenance work

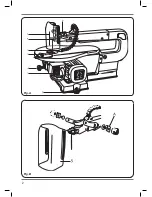

Installing the protective cover

Fig.B

• Before commissioning the machine, the

protective cover (5) must be installed.

• Insert the screw from the inside left, then affix

the washer and the safety ring from the right

side. The safety ring (A) may be left out

optionally.

• Screw the knurled nut in tight.

Installing the cross guide

Fig.C

The cross guide (3) allows material to be bevelled,

and can be simultaneously used to support the

material as it is fed through the saw.

Mounting the rubber feet

Fig. G

The enclosed rubber feet contribute to a steady

position of the scroll saw on your worktable

• Place the rubber foot on its place

• Connect the rubber foot with help of the

enclosed bolt, ring and nut

• Tighten the nut with a wrench

Sawdust blower

Fig. H

The sawdust blower keeps the workpiece clean for

more accurate scroll cuts. For best results, always

direct air flow from the blower tube at blade and

workpiece. To adjust, simply bend to desired

position.

Installation

• Place the sawdust blower on the hole on top of

the machine

• Turn the blow pipe clockwise into the hole

4. OPERATION

Always observe the safety instructions

and obey the relevant regulations.

Start - Push the green ON-switch to start the

machine

Stop - Push the red OFF-switch to stop the

machine

Tilting the table

Fig.D

The scroll saw table can be tilted through 45°.

To do so:

• Lock the locking arm underneath the table.

• Manually tilt the table until the desired angle

Summary of Contents for SSM1005

Page 2: ...2 Fig B Fig A ...

Page 3: ...3 Fig C Fig D Fig E ...

Page 4: ...4 Fig F Fig G Fig H ...

Page 81: ...81 80 81 Artikel SSM 1005 Model FFZ 400R Exploded view ...

Page 82: ...82 ...

Page 84: ...www ferm com 2016 FERm B V 1605 26 www ferm com 2017 FERm B V 1705 30 ...