EN

3

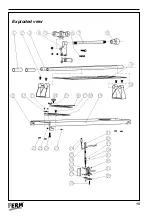

directly below the blade.

3. Firmly hold the tile and cut several times (at

least 4) along the mark. After each cut, press

the lever more firmly.

4. Lift the lever when it has reached the front

edge of the tile and moved it backward.

5. Subsequently the break-off unit is lifted.

Repeat along the full width of the tile until the

notch is sufficiently deep.

The cutting movement results from

moving the lever from the back edge of

the tile towards its front, while lightly

pressing the lever.

Wall tiles

(single baked)

Lift the lever and position the break-off unit in the

middle of the tile. Press the lever down and the tile

will break.

Floor tiles

(double-baked):

Sometimes these much harder tiles cannot be cut

in two by means of the break-off unit (K) on the tile

cutting machine.

In these cases after making the notch the tile must

be broken in two by tapping the underside of the

tile with a light hammer along the full length of the

notch. This way the break line will spread through

the tile, and cause the tile to break in two along

the line. By means of the wing nut (Q) the angle of

the stop can be adjusted.

Making holes by means of the (hand) drill

1. Mount the drill attachment including the drill

over the centre of the hole in the base. It

is important that the drill and the blade are

adjusted in such a way that they just touch the

base. This adjustment can be made by means

of the upper two nuts.

Make sure to tighten the nuts after

adjustment.

Place the tile underneath the drill, the glazed

side facing upwards. By squeezing the

grips the tile can accurately be positioned

underneath the drill.

2. Moving the blade away from the centre will

enlarge the diameter of the hole. NB. The

scale on the blade holder indicates the radius

of the hole, i.e. the diameter is twice this

length.

3. By turning the handle clockwise, first a small

hole is drilled and subsequently a larger hole

of the correct size.

4. Do not press the handle while it is turned, this

may cause the tile to break.

5. Maintenance

The guide rods and the drill attachment do not

•

require greasing.

After use remove any dust from the machine

•

and store it in a dry place. If you expect the

machine will not be used for some time, it is

best to apply a thin coating of oil to the guide

rods and the lever.

Periodical maintenance of the tile cutting

machine prevents unnecessary

problems.

Replacing the knife

If the knife is worn, it can be replaced by a new

model.

This is done as follows:

Loosen the screw with which the knife is

•

fastened and remove the knife from the

machine. Replace this knife by a new one and

fasten the screw again.

Guarantee

For the conditions of guarantee, please refer to

the separately provided guarantee card.