FERNO/MAN/0721/220-R2/UK

10

5.1 Daily pre-checks

•

Prior to using ensure to check the overall condition

of the unit for any signs of damage / missing parts

•

Check for correct operation of the emergency

release pins

•

Check for correct operation of the clamp fixing-bars

and look for any signs of damage / wear

•

Check for correct operation of the ratcheting fixing

bars and look for any signs of damage / wear

•

Check the condition of the straps. Replace if any

damage is found

•

Check for loose / missing hardware. Tighten/replace

where necessary

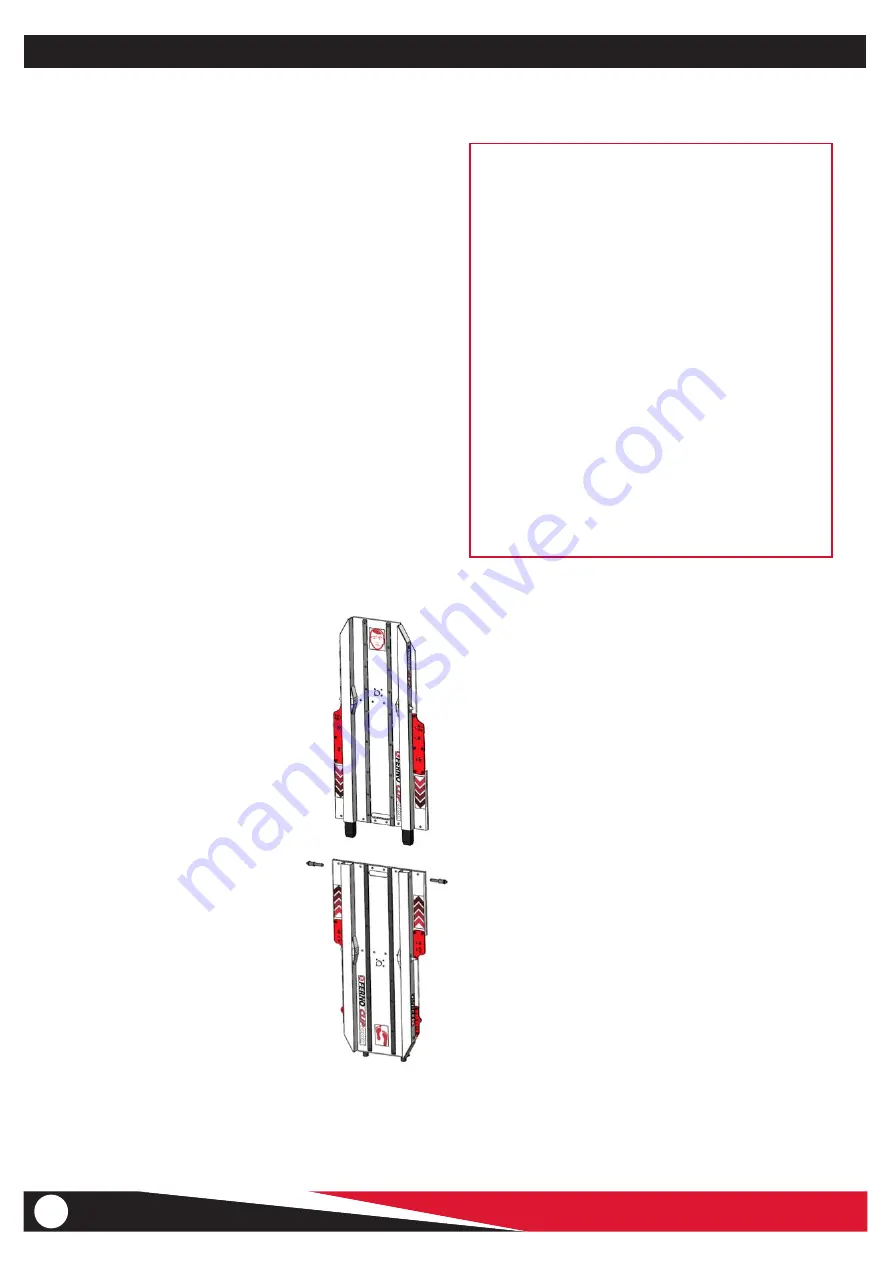

5.2 Assembly of UNI-ClipDoc

UNI-ClipDoc can be split into two sections to aid storage

and transport when not in use. Assembly / dis-assembly

of the UNI-ClipDoc requires two operators and does not

require the use of any tools. The UNI-ClipDoc should be

assembled on a smooth, level surface and debris gloves

should be worn to avoid any possible operator injury.

•

Remove the two halves of the

UNI-ClipDoc from their storage

bags and check all items are

present and in good condition

before proceeding. Each

section is marked to denote

head-end and foot-end.

•

Stand the foot-end section of

the unit upright on the rubber

feet.

•

Whilst the first operator holds

the foot-end section upright,

the second operator can then

lift the head-end section up

and insert the black spigots

into the sockets on the foot-

end section.

•

Keeping fingers clear, push

down on the head-end section

to ensure the pegs are fully

inserted and no gap exists

between the two sections.

•

Insert the spring loaded

locking pins (one on each side)

5.0 - OPERATION OF UNI-CLIPDOC

TO PREPARE THE AMBULANCE TROLLEY FOR

INSTALLATION OF THE UNI-CLIP DOC:

•

APPLY THE BRAKES TO PREVENT THE

TROLLEY FROM MOVING DURING

INSTALLATION

•

REMOVE THE PATIENT HARNESS AND LEG

RESTRAINTS

•

REMOVE THE MATTRESS

•

FOLD THE COTSIDES/ SURFACE EXTENDERS

INTO THE VERTICAL DOWN POSITION

•

LOWER THE BACK REST AND LEG RAISE

PANELS INTO THE FULLY FLAT POSITIONS

•

REMOVE ANY OTHER ACCESSORIES WHICH

MAY INTERFERE WITH CORRECT OPERATION

OF THE UNI-CLIP DOC

5.3 Installing the fixing-bars

First determine the type of fixing-bar required depending

on the model of trolley to be used for transport. Using the

installation drawing and the position labels on the UNI-

ClipDoc itself, determine the correct positions where the

fixing -bars should be attached to the UNI-ClipDoc, which

is dependant on the trolley type being used.

The abbreviated trolley names etched onto the

UNI-ClipDoc are as follows:

P = FERNO PEGASUS

M = FERNO MEGASUS

H = FERNO HARRIER / HARRIER LT

PX = FERNO POWERX

INX = FERNO INX

S = STRYKER POWER PRO

Both variants of fixing bar attach to the

UNI-ClipDoc in the same manner, using two

thumbscrews per fixing-bar

Tighten the thumbscrews by hand only. Do

not use tools to tighten the thumbscrews

UNI-ClipDoc