FERNO/MAN/0721/220-R2/UK

17

Maintenance

7 - MAINTENANCE

7.1 - Maintenance Schedule

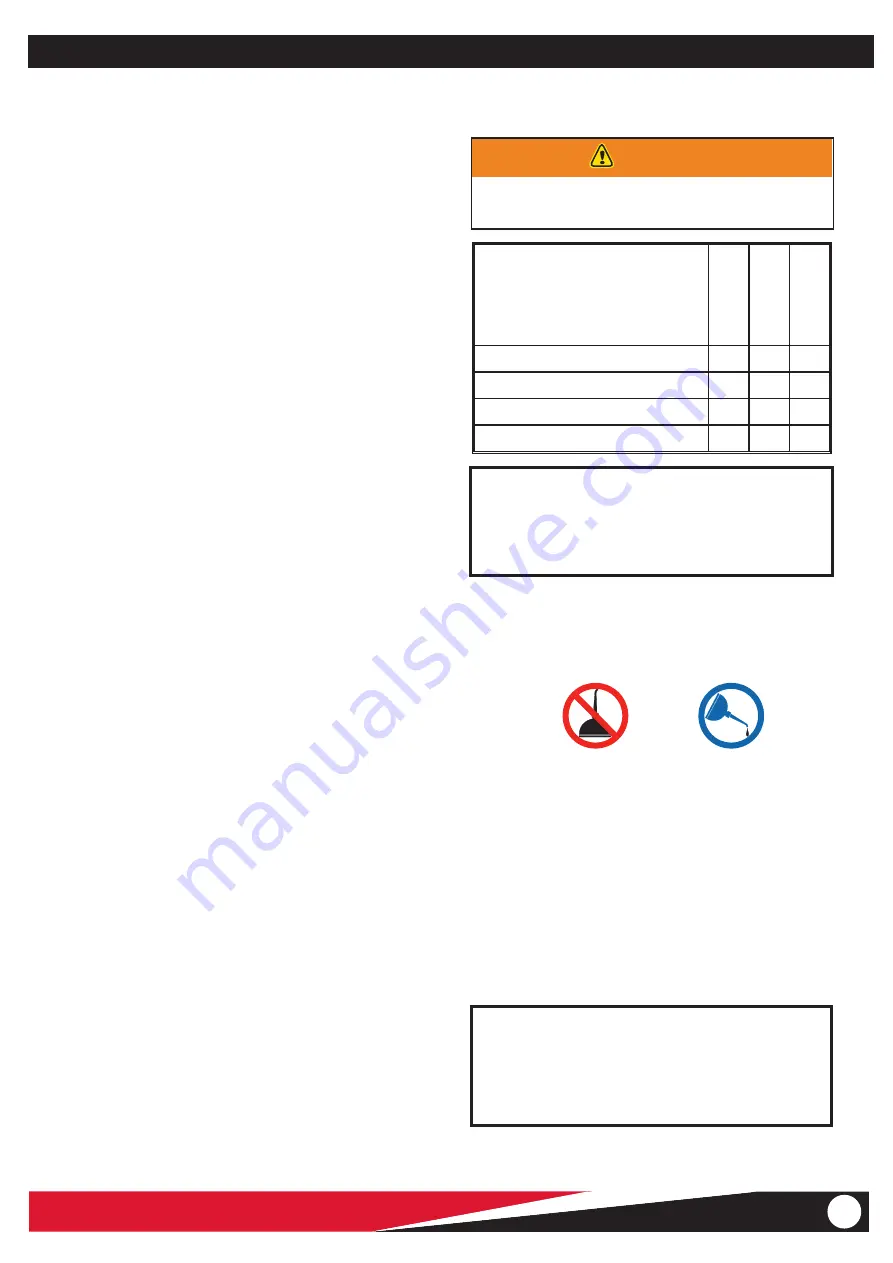

The Uni-ClipDoc and Ambulance trolley used both require regular

preventative maintenance. Set up and follow a maintenance

schedule. The table at right/below represents minimum intervals

for maintenance.

It is suggested that the Ambulance trolley and UNI-ClipDoc used

for a transportation is visually inspected after every completed

patient transfer.

Keep maintenance records. A sample maintenance record sheet is

provided at the end of this manual.

When using maintenance products, follow the manufacturers’

directions and read the manufacturers’ material safety data sheets.

You can purchase a recommended disinfectant from your Ferno

distributor or Ferno UK Service Department.

7.2 - Disinfection of UNI-ClipDOC

Clean the unit and component parts regularly using warm water

and a mild soap or detergent.

Do not use high pressure washers

Wipe all surfaces with disinfectant. Follow the disinfectant

manufacturer’s instructions for application method and contact

time. Ferno recommends you inspect the equipment for damage

as you clean or disinfect it.

Minimum

Maintenance Intervals

Each U

se

A

s N

eeded

Each M

on

th

Disinfecting

•

Cleaning

•

Inspecting

•

•

Lubricating (trolley)

•

IMPORTANT

Disinfectants and cleaners containing bleach, phenolic, or

iodine can cause damage. Do not use products containing

these chemicals.

7.3 - Cleaning the Ambulance Trolley

Regular cleaning helps reduce the risk of transmitting disease and

enables equipment to function at its optimum.

Steam cleaning or power washing of the trolley with a suitable

cleaning additive is the most effective method of cleaning.

Although sealed to IPX6 rating, avoid spraying directly onto

the electrical components. When using a steam cleaner or jet

wash, ensure to operate at a safe working distance and with the

cleaning nozzle at all times positioned at least 8inch / 20cm from

the surface being cleaned, using water at a temperature no more

than 60

º

C / 140

º

F.

Wipe all surfaces with disinfectant. Follow the disinfectant

manufacturer’s instructions for application method and contact

time. Ferno recommends you inspect the trolley for damage as

you clean and disinfect it.

1. Remove the mattress, restraints and any accessories.

2. Hand clean all surfaces of the trolley with warm water and a

mild detergent.

3. Rinse with warm, clear water. Dry the trolley with a towel

and allow it to air-dry thoroughly, replacing the mattress and

harness/restraints prior to storage.

Once cleaned, dry the trolley with a soft towel, paying particular

attention to swivel and sliding joints. If a compressed air hose is

available, you may find that compressed air jets are more effective

in drying the hard-to-reach places.

7.4 - Reattachment of Mattress and

Restraints after using UNI-ClipDoc

Ensure that the mattress and trolley patient restraints are placed

back on the trolley after each patient transfer using UNI-ClipDoc

has been completed. Take extra care to ensure that the restraint

straps are correctly re-attached to the trolley.

7.5 - Lubrication of Trolley parts

Disinfect and clean the trolley before applying lubricant. Use

the lubricants designated below to lubricate the trolley. Do not

lubricate points marked with the “do not lubricate” symbol.

Your Ferno Trolley will work efficiently and safely only when it is

lubricated. You MUST lubricate all moving and sliding parts after

every inspection or preventative maintenance programme, or if

there is inadequate lubrication for the moving parts to operate

easily and quietly.

In general terms, almost all sliding and moving parts may be

lubricated with light duty grease. A penetrating fluid lubrication

is used on some sliding parts of the trolley. However, when a

penetrating fluid lubricant is used, all excess

MUST

be wiped

away, to prevent any build-up of dust or grime which can clog up

working parts and impede movement.

Do Not Lubricate

Lubricate

IMPORTANT

Lubricating parts that should not be lubricated allows

dirt and foreign particles to collect on those parts,

resulting in damage. Lubricate

only

the numbered

reference points shown.

WARNING

Improper maintenance can cause injury. Maintain the

trolley and UNI-ClipDoc only as described in this manual.