FERNO/MAN/0721/220-R2/UK

7

3 - ABOUT THE UNI-CLIPDOC

About the UNI-ClipDoc

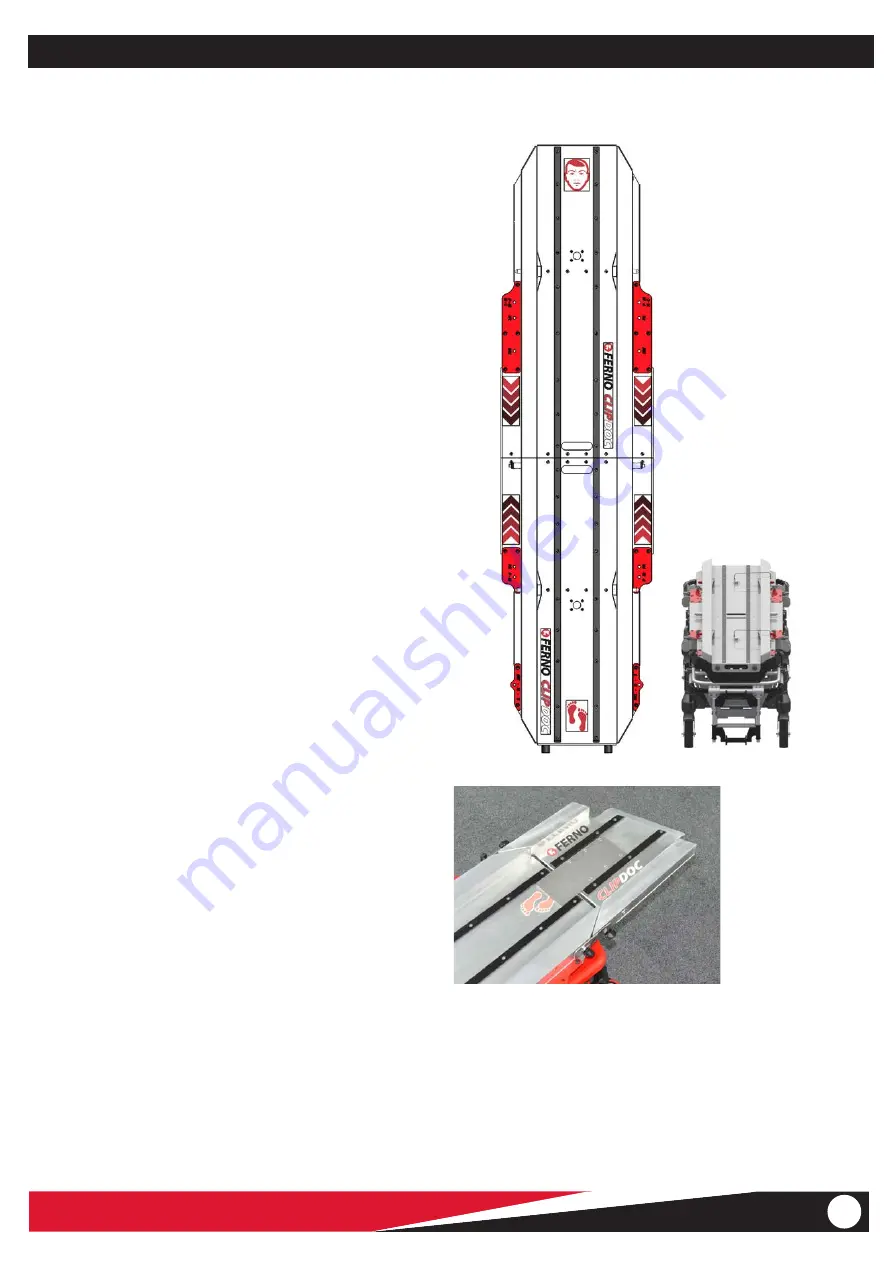

3.1 - Product Overview

UNI-ClipDoc is an interface designed to allow patient-carrying

equipment such as incubators and patient platforms like the

LifePort AeroSled TS to be transferred from a helicopter or aircraft

onto an ambulance trolley, providing a secure system to hold the

patient on the trolley, to then directly transfer into an Ambulance

for the remainder of the journey, thereby providing a safe and

seamless transport of patients by air and by road.

UNI-ClipDoc consists of two plates which attach together to

form a platform which can be attached to any of Ferno's range

of ambulance trolleys. The platform emulates the locking

mechanism on the floor of the air ambulance, thereby allowing

any patient platform that is used in an aircraft to be also locked

onto the top of an ambulance trolley.

The product is supplied with 2 different sets of "cross-member"

fixing brackets, the first set incorporating a ratchet mechanism,

allowing the UNI-ClipDoc to be attached to trolleys that have a

top-frame to attach to, such as Ferno's Pegasus, Megasus and

Harrier and Stryker's PowerPro TL.

The second fixing bracket set incorporates a clamping mechanism

which allows the UNI-ClipDoc to be clamped to the integral

siderail interface on both PowerX and iNX trolleys, providing a

safe and quick method of attachment and detachment.

Assembly and attachment of the UNI-ClipDoc using the supplied

two sets of brackets is explained in detail later in this manual.

Procedure for attachment of the incubator or patient platform

to the UNI-ClipDoc follows the similar method of attaching to

the aircraft floor. Details of the platform locking mechanism are

explained in more detail.

All components are supplied in storage bags with carry handles,

allowing for easy storage, moving and access of the product as

and when required.

3.2 - Auxiliary Bridging plate (Optional)

Also available as an option for UNI-ClipDoc is a bridging plate, to

bridge the gap between aircraft floor and trolley where the trolley

cannot be brought directly up to the aircraft, facilitating transfer

directly from aircraft floor to UNI-ClipDoc without the need to lift

the patient platform. The bridging pate is available in different

lengths according to the gap that needs to be bridged.

Instructions on using the optional bridging plate are included

in a separate instruction sheet supplied with the bridging plate

itself as this may differ according to requirements.